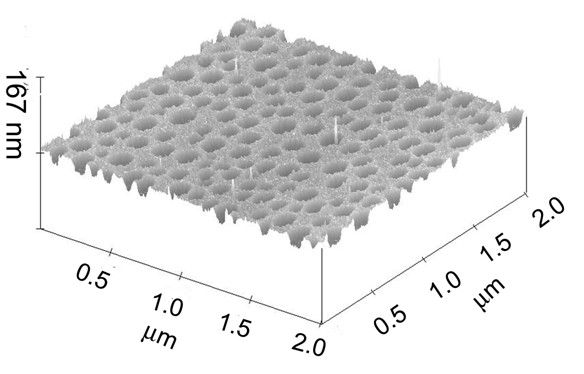

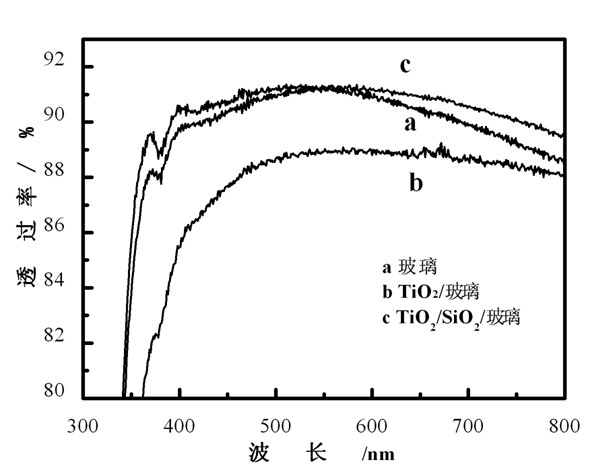

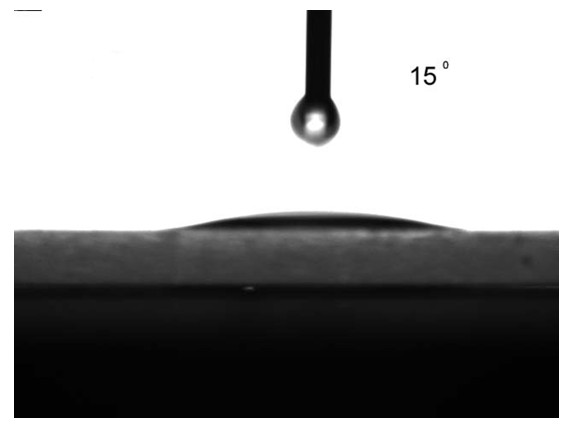

Preparation method of superhydrophilic TiO2/SiO2 porous bilaminar membrane

A technology of titanium dioxide and silicon dioxide, which is applied in the field of nanomaterials, can solve problems such as low transmittance and large refractive index, and achieve high transmittance and good anti-fog effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Ultrasonic cleaning of ordinary glass with acetone, absolute ethanol, and deionized water for 15 minutes in sequence.

[0025] (2) Add 10.0 m1 of Ti(OC 4 h 9 ) 4 (content ≥98%, density 0.999-1.003g / ml) dissolved in 350ml of absolute ethanol (analytical purity ≥99.7%, density 0.789-0.791g / ml); then add 14.5 ml of diethanolamine (analytical pure) , stirred vigorously on a constant temperature magnetic stirrer at room temperature for 2 hours; then added a volume ratio of H 2 O:C 2 h 5 OH=1.0ml:10.0 ml mixed solution, continue to stir for about 10 minutes to obtain a uniform, transparent light yellow sol; age at room temperature for 48 hours to obtain a uniform and stable titanium dioxide sol; add polymer polyethylene glycol 2000, A mixed solution of polyethylene glycol 2000 and titanium dioxide was obtained (the mass percentage of polyethylene glycol 2000 was 0.45 %).

[0026] (3) Mix 7.0ml of deionized water and 40.0ml of absolute ethanol, use magnetic stirring ...

Embodiment 2

[0031] (1) Ultrasonic cleaning of ordinary glass with acetone, absolute ethanol, and deionized water for 15 minutes in sequence.

[0032] (2) 12.0 m1 of Ti(OC 4 h 9 ) 4 (content ≥98%, density 0.999-1.003g / ml) dissolved in 400ml of absolute ethanol (analytical purity ≥99.7%, density 0.789-0.791g / ml), then add 15.2 ml of diethanolamine (analytical pure) , stirred vigorously on a constant temperature magnetic stirrer for 2 hours at room temperature, and then added a volume ratio of H 2 O:C 2 h 5 0H=1.08ml: 10.8 ml mixed solution, continue stirring for about 20 minutes, obtain uniform, transparent light yellow sol; aging at room temperature for 50 hours, obtain uniform and stable titanium dioxide sol; add polymer polyethylene glycol 2000 , to obtain a mixture of polyethylene glycol 2000 and titanium dioxide (mass percentage of polyethylene glycol 2000 is 0.5%).

[0033] (3) Mix 9.0ml of deionized water and 40.0ml of absolute ethanol, use magnetic stirring for 25 minutes, and...

Embodiment 3

[0038] (1) Ultrasonic cleaning of ordinary glass with acetone, absolute ethanol, and deionized water for 15 minutes in sequence.

[0039] (2) 12.0 m1 of Ti(OC 4 h 9 ) 4 (content≥98%, density 0.999-1.003g / ml) dissolved in 450ml of absolute ethanol (analytical purity≥99.7%, density 0.789-0.791g / ml), then add 15.5 ml of diethanolamine (analytical pure) , stirred vigorously on a constant temperature magnetic stirrer for 2 hours at room temperature, and then added a volume ratio of H 2 0:C 2 h 5 0H=1.06ml: 10.8 ml mixed solution, continue to stir for 30 minutes, obtain uniform, transparent light yellow sol; Aging at room temperature for 50 hours, obtained uniform and stable titanium dioxide sol; Add polymer polyethylene glycol 2000, obtain A mixed solution of polyethylene glycol 2000 and titanium dioxide (0.5% by mass of polyethylene glycol 2000).

[0040] (3) Mix 10.0ml of deionized water and 45.0ml of absolute ethanol, use magnetic stirring for 35 minutes, and record it as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com