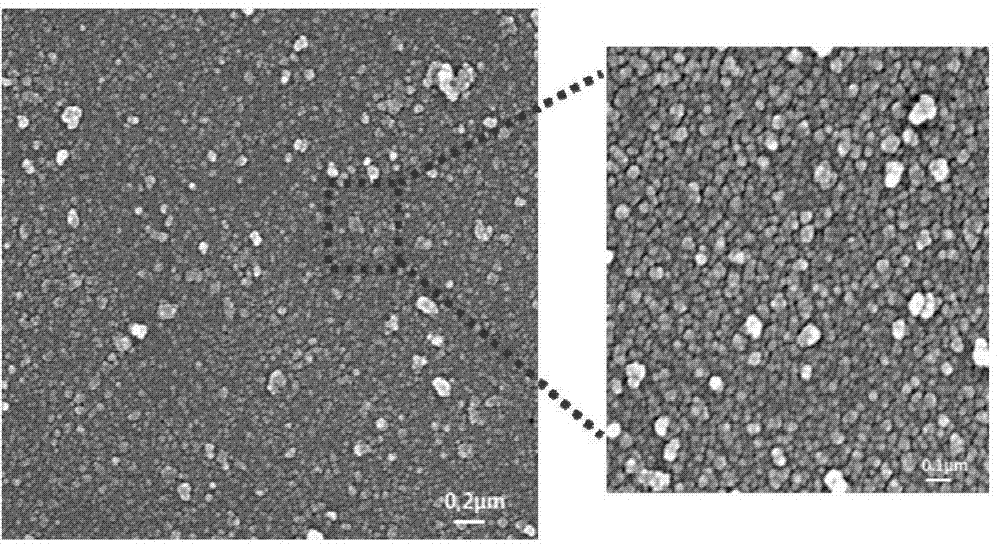

Preparation method of superhydrophilic/superhydrophobic composite nanofiltration membrane

A composite nanofiltration membrane, super-hydrophobic technology, applied in the field of membrane separation, can solve the problems of no super-hydrophilic/super-hydrophobic, single function, etc., achieve good organic solvent resistance nanofiltration effect, wide source, high retention rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An organic-inorganic composite nanofiltration membrane with superhydrophilicity and superhydrophobicity and a preparation method thereof, comprising the following steps:

[0030] (1) Take the polyvinylidene fluoride ultrafiltration membrane as the base membrane, treat it with 4mol / L sodium hydroxide alkali solution at 50°C for 40min, and rinse the membrane surface with deionized water until the pH is neutral; (2) The pretreated polyvinylidene fluoride-based membrane was immersed in 8g / L polydimethyldiallylammonium chloride polyelectrolyte solution, and was taken out after 30min, and the excess polyelectrolyte on the membrane surface was rinsed with deionized water; (3) ( 2) Immerse the membrane in 4g / L sodium polystyrene sulfonate polyelectrolyte solution, take it out after 30min, and rinse the excess polyelectrolyte on the surface of the membrane with deionized water; (4) Repeat steps (2) and (3) to assemble twice , to obtain a dense pre-separation layer; (5) immerse t...

Embodiment 2

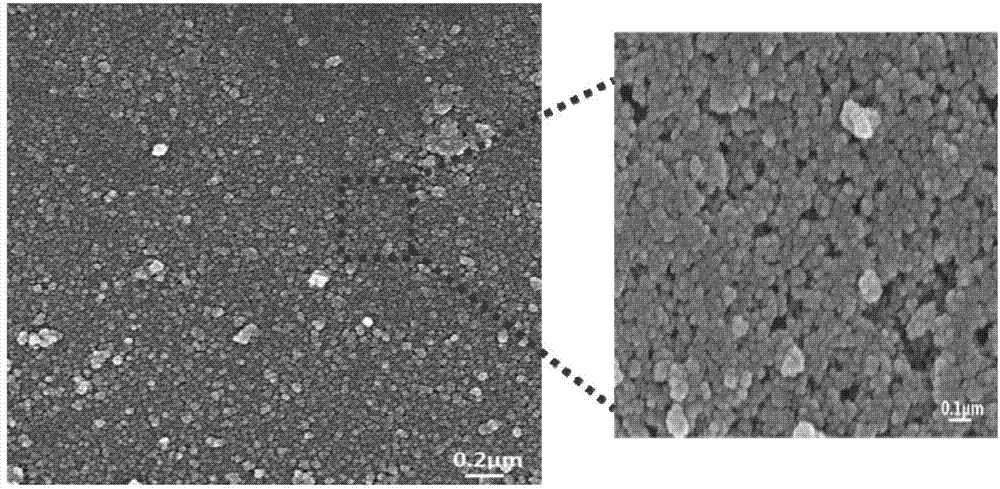

[0033] An organic-inorganic composite nanofiltration membrane with superhydrophilicity and superhydrophobicity and a preparation method thereof, comprising the following steps:

[0034] (1) Use polysulfone ultrafiltration membrane as the base membrane, treat it with 2mol / L sodium hydroxide lye at 30°C for 80min, wash the membrane surface with deionized water until the pH is neutral; (2) pretreat The final polysulfone-based membrane is immersed in 4g / L polyvinylamine polyelectrolyte solution, taken out after 60min, and the excess polyelectrolyte on the surface of the membrane is rinsed with deionized water; (3) The membrane of (2) is immersed in 1g / L seaweed Sodium acid polyelectrolyte solution, take it out after 60min, and rinse the excess polyelectrolyte on the surface of the membrane with deionized water; (4) Repeat steps (2), (3) to assemble twice to obtain a dense pre-separation layer; (5) ( 4) Immerse the membrane in 4g / L polyvinylamine polyelectrolyte solution containing...

Embodiment 3

[0037] An organic-inorganic composite nanofiltration membrane with superhydrophilicity and superhydrophobicity and a preparation method thereof, comprising the following steps:

[0038] (1) Take the polyacrylonitrile ultrafiltration membrane as the base membrane, treat it with 3mol / L sodium hydroxide alkali solution at 40°C for 60min, wash the membrane surface with deionized water until the pH is neutral; The treated polyacrylonitrile-based membrane was immersed in 5g / L polyethyleneimine polyelectrolyte solution, taken out after 40min, and the excess polyelectrolyte on the surface of the membrane was rinsed with deionized water; (3) the membrane of (2) was immersed in 1g / L polyelectrolyte solution. sodium acrylate polyelectrolyte solution, take it out after 40min, and rinse the excess polyelectrolyte on the surface of the membrane with deionized water; (4) repeat steps (2), (3) to assemble twice to obtain a dense pre-separation layer; (5) ( 4) The membrane is immersed in 5g / L ...

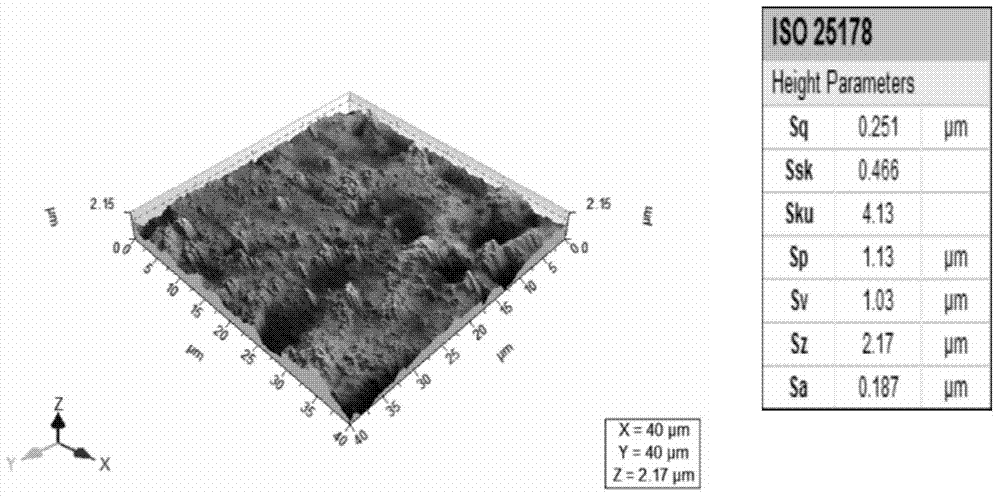

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com