Preparation method for scale-adjustable nano porous metal material

A technology of nanoporous and metal materials, applied in the field of preparation of nanoporous metal materials, can solve the problems of high cost, lack of multi-scale features, complex preparation of template method, etc., and achieve the effect of low cost, reliable strength and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

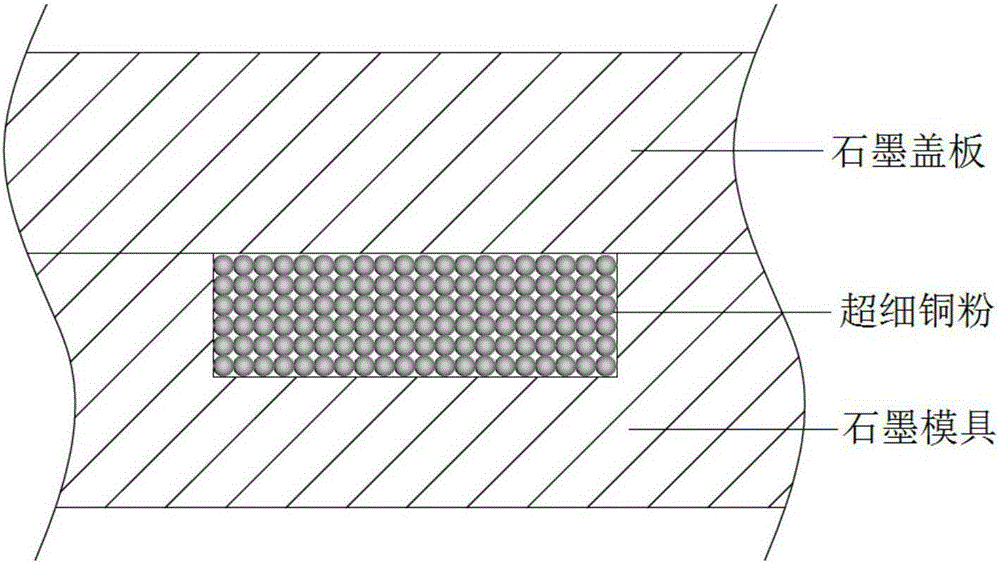

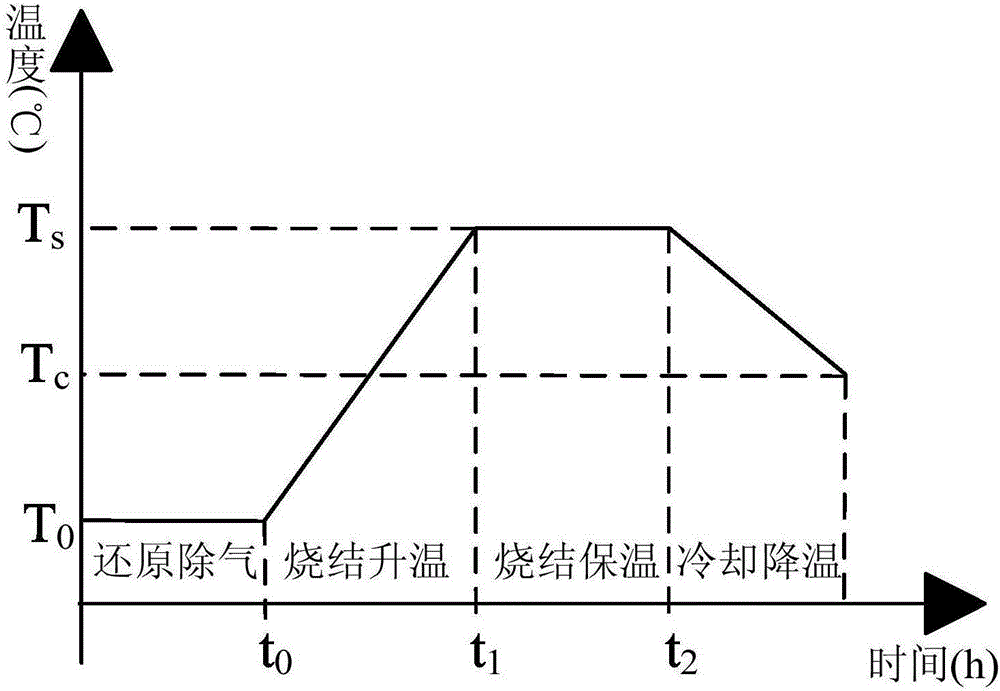

[0033] Example 1: Using pure copper powder with an average particle size of 400nm, uniformly mixed with Na with a particle size of 75 μm to 106 μm 2 CO 3 powder, where Na 2 CO 3 The mass content of powder is 11%. Spread the mixed powder evenly in the graphite mold, press the graphite cover plate, and send them into the sintering furnace for sintering. The heating time is 3h, and the sintering temperature T S The temperature is 650°C, and the holding time is 1h.

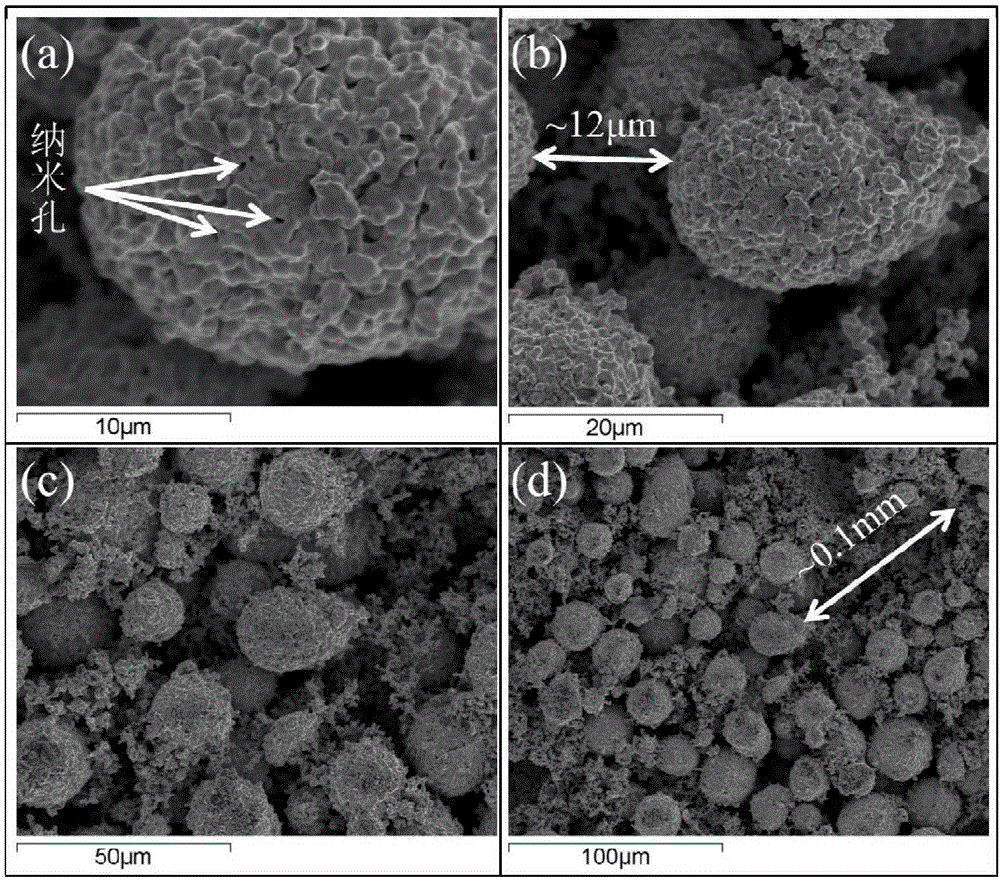

[0034] The morphology of the porous body is obtained as image 3 shown. During the sintering process, due to the agglomeration of the powder, agglomerated balls are formed inside the porous body, and the balls contain a large number of nanopores with a pore size between 100nm and 500nm. There are also pores between the balls, and the pore diameter is between 5 and 25 μm. At the same time, due to Na 2 CO 3 Due to the action of the powder, a long moat with a length of about 0.1mm is also produced in the porous ...

Embodiment 2

[0035] Example 2: Pure copper powder with an average particle size of 400 nm is used, and NaCL powder with a particle size of 75 μm˜106 μm is uniformly mixed in, wherein the mass content of NaCL powder is 15%. Spread the mixed powder evenly in the graphite mold, press the graphite cover plate, and send them into the sintering furnace for sintering. The heating time is 3h, and the sintering temperature T S The temperature is 700°C, and the holding time is 1h.

[0036] The morphology of the porous body is obtained as Figure 4 shown. can be seen, with image 3 In contrast, there are no nanopores on the agglomerated spheres, and there are mainly two pore scales of micron and millimeter in the porous body.

Embodiment 3

[0037] Example 3: Pure copper powder with an average particle size of 400 nm is used, and KCL powder with a particle size of 75 μm˜106 μm is evenly mixed in, wherein the mass content of the KCL powder is 5%. Spread the mixed powder evenly in the graphite mold, press the graphite cover plate, and send them into the sintering furnace for sintering. The heating time is 3h, and the sintering temperature T S The temperature is 600℃, and the holding time is 1h. After the heat preservation is over, when the temperature drops to 300°C, open the valve to oxidize.

[0038] The morphology of the porous body is obtained as Figure 5 shown. can be seen, with image 3 In contrast, the porous body obtained in this example not only retains the nano-micro-milliscale pore structure, but also significantly increases the roughness of the metal substrate surface, so that the surface wettability of the porous body can be further adjusted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com