Polished rod sealing device

A polished rod sealer and polished rod technology, which is applied in sealing/packing, engine sealing, wellbore/well parts, etc., can solve the problem of not being able to better seal the wellhead of the pumping well, the lower part cannot be temporarily sealed, and there is no broken rod Blowout prevention and other issues to achieve the effect of avoiding crude oil loss, preventing blowout phenomenon, and reducing eccentric wear of packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

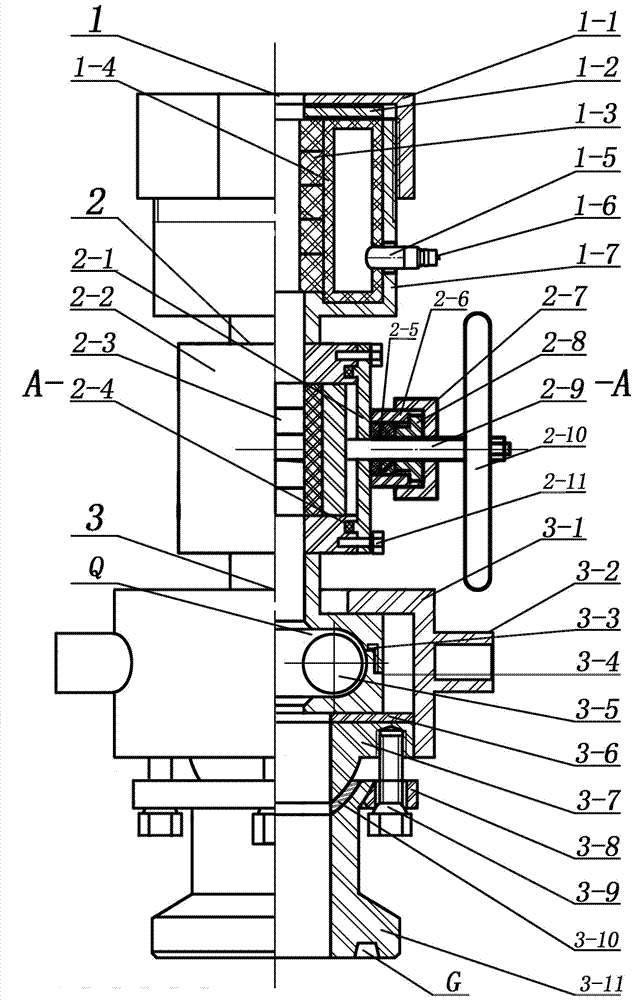

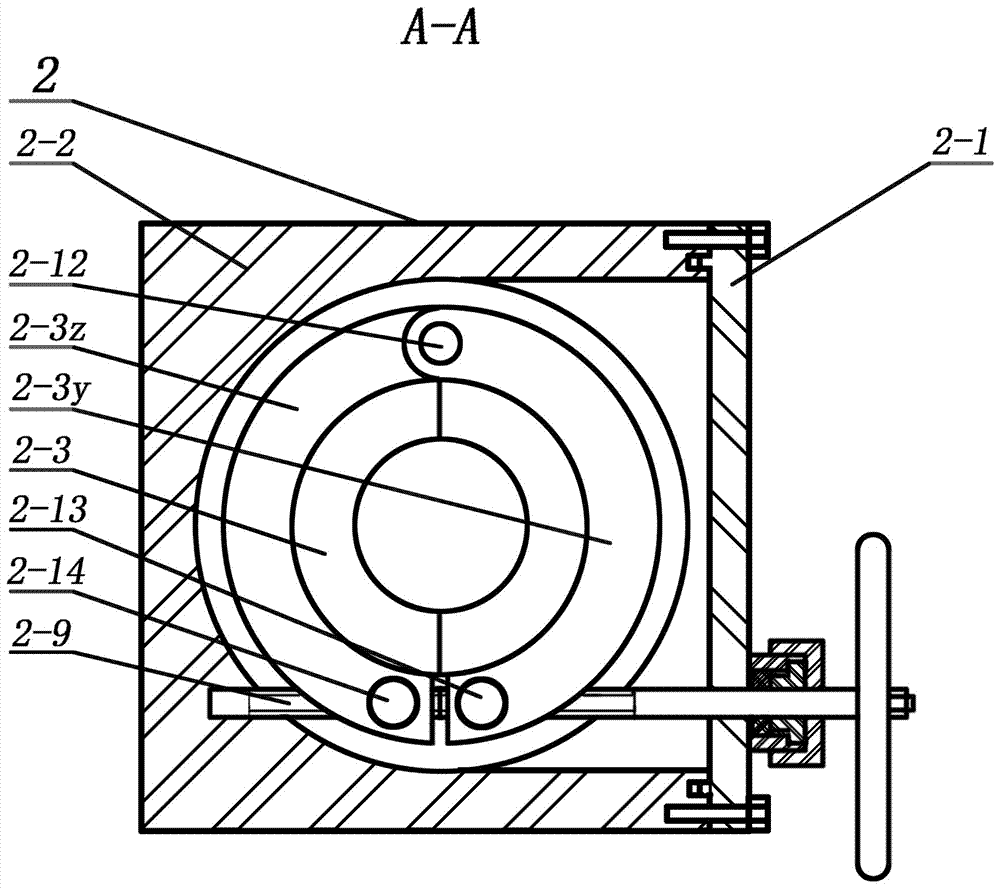

[0027] The present invention will be further described below in conjunction with accompanying drawing:

[0028] Such as figure 1 , figure 2 As shown, a polished rod sealer includes: a primary seal assembly 1, a secondary seal assembly 2, and a deflection adjustment blowout prevention assembly 3. It is characterized in that: the main sealing assembly 1 is located at the upper part, the main sealing cavity 1-7 of the main sealing assembly 1 is provided with a main sealing packing 1-3, and a pressure bag 1 is arranged around the main sealing packing 1-3 -4, the lower part of the pressure bag 1-4 is provided with an inlet pipe 1-5, the inlet pipe 1-5 passes through the main sealing chamber 1-7, and the inlet pipe 1-5 is provided with a quick male plug 1 with a check valve -6, the upper part of the main sealing packing 1-3 and the pressure bag 1-4 is provided with a pressing plate 1-2, an upper pressing cap 1-1, and the upper pressing cap 1-1 is threadedly connected with the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com