Method for preparing multi-grade antimonytelluride nano wire harness array by adopting physical vapour deposition

A physical vapor deposition and antimony subtelluride nanotechnology, which is applied in chemical instruments and methods, polycrystalline material growth, ion implantation plating, etc., can solve the problem of general electrical performance of thermal antimony telluride nanowires and difficulty in achieving micro-cooling The linear density requirements of the device and the difficulty of large-scale production have achieved the effects of easy large-scale production, high cooling power density, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Physical Vapor Deposition of Antimony Telluride Nanowire Arrays on Glass Substrates

[0038] (A) Pressing antimony telluride powder with a mass percent purity of 99.999% into an antimony telluride block under a pressure of 8 MPa; the average particle size of the antimony telluride powder is less than 50 μm;

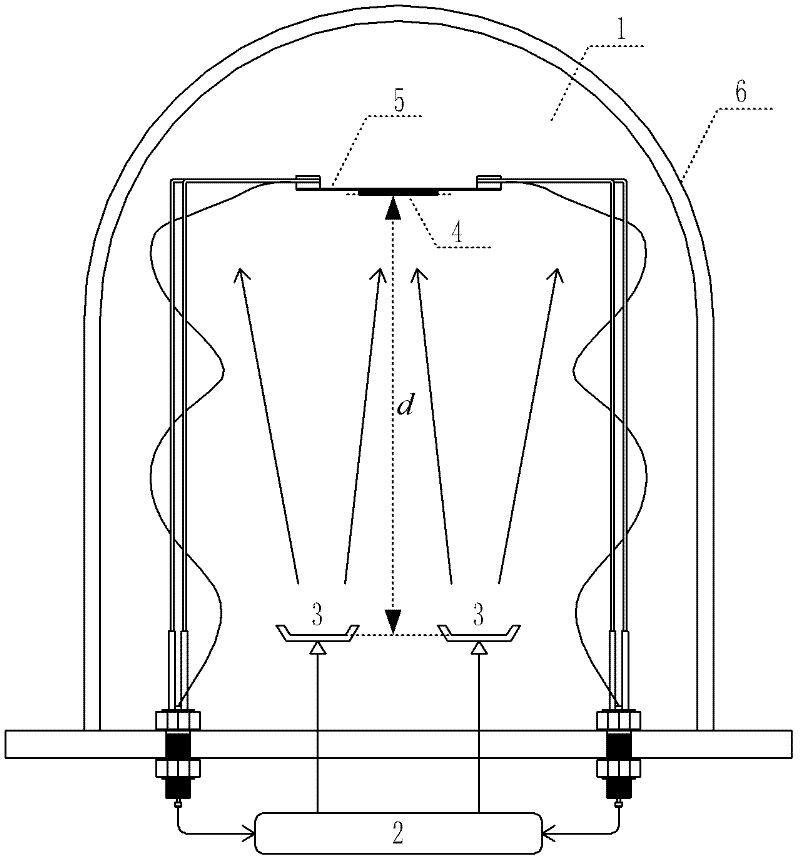

[0039] (B) Put the antimony telluride block into the tungsten boat 3 in the vacuum chamber 1 of the vacuum coating machine, place the glass substrate 4 (or glass plate) on the sample stage 5, and adjust the relationship between the glass substrate 4 and the tungsten boat 3 Distance d=4cm;

[0040](C) Fill the vacuum chamber 1 with nitrogen gas (high-purity nitrogen gas, mass percent purity 99.999%) for 3 minutes and then stop, then fill with nitrogen gas for 3 minutes and then stop, then vacuumize the vacuum chamber 1 to make the vacuum chamber 1 vacuum. up to 2.0×10 -4 Pa;

[0041] (D) Set deposition rate 18nm / min on PID controller 2, deposition ti...

Embodiment 2

[0046] Example 2: Physical Vapor Deposition of Antimony Telluride Nanowire Arrays on CPU Processors

[0047] (A) Pressing antimony telluride powder with a mass percent purity of 99.999% into an antimony telluride block under a pressure of 10 MPa; the average particle size of the antimony telluride powder is less than 50 μm;

[0048] (B) Put the antimony telluride block into the tungsten boat 3 of the vacuum chamber 1 of the vacuum coating machine, place the CPU processor on the sample stage 5, adjust the distance d=6cm between the CPU processor and the tungsten boat 3;

[0049] (C) Fill the vacuum chamber 1 with nitrogen gas (high-purity nitrogen gas, mass percent purity 99.999%) for 5 minutes and then stop, then vacuumize the vacuum chamber 1 so that the vacuum degree in the vacuum chamber 1 reaches 2.0×10 -4 Pa;

[0050] (D) Set deposition rate 15nm / min on PID controller 2, deposition time 5h;

[0051] (E) Turn on the AC power supply and adjust the output current to 170A...

Embodiment 3

[0056] Example 3: Physical Vapor Deposition of Antimony Telluride Nanowire Arrays on Glass Substrates

[0057] (A) Pressing antimony telluride powder with a mass percentage purity of 99.999% into an antimony telluride block under a pressure of 9 MPa; the average particle size of the antimony telluride powder is less than 50 μm;

[0058] (B) Put the antimony telluride block into the tungsten boat 3 of the vacuum chamber 1 of the vacuum coating machine, place the glass substrate 4 on the sample stage 5, and adjust the distance d=8cm between the glass substrate 4 and the tungsten boat 3;

[0059] (C) Fill the vacuum chamber 1 with nitrogen gas (high-purity nitrogen gas, mass percent purity 99.999%) for 3 minutes and then stop, then vacuumize the vacuum chamber 1 so that the vacuum degree in the vacuum chamber 1 reaches 2.5×10 -4 Pa;

[0060] (D) Set deposition rate 10nm / min on PID controller 2, deposition time 7h;

[0061] (E) Turn on the AC power supply, adjust the output cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com