Super-hydrophilic particle hybridized super-hydrophobic coating and preparation method thereof

A super-hydrophobic coating and super-hydrophilic technology, applied in the direction of coating, etc., can solve the problems of complex preparation process and method, unsuitable for large-area application, and limited single substrate, so as to increase the adhesion of droplets and promote the collection Water efficiency, easy desorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a superhydrophobic coating hybridized with superhydrophilic particles, the steps are:

[0035] (1) Pre-treatment: The metal substrate is polished with 800#, 1000#, 1500# sandpaper in sequence, mechanically polished, and then ultrasonically cleaned with acetone, absolute ethanol and deionized water for 15 minutes, and dried with cold air for later use. The substrate can be a copper sheet , nickel sheet, aluminum sheet, stainless steel sheet and other metal substrates, or inorganic materials such as glass and ceramics, or polymer materials such as polypropylene, polyethylene, polyurethane, etc. The shape can be flat surface, curved surface or special shape surface;

[0036] (2) Preparation of superhydrophobic coating solution:

[0037]Under the condition of water bath at 20-40°C, add 50-100 parts of absolute ethanol, 1-5 parts of ammonia water, and 5-10 parts of deionized water into the reaction kettle, stir at a speed of 1500r / min, and add 0.5- 5...

Embodiment 1

[0040] Example 1 Preparation of Nano-SiO by Copper Substrate Substrate Spraying Method 2 superhydrophobic coating

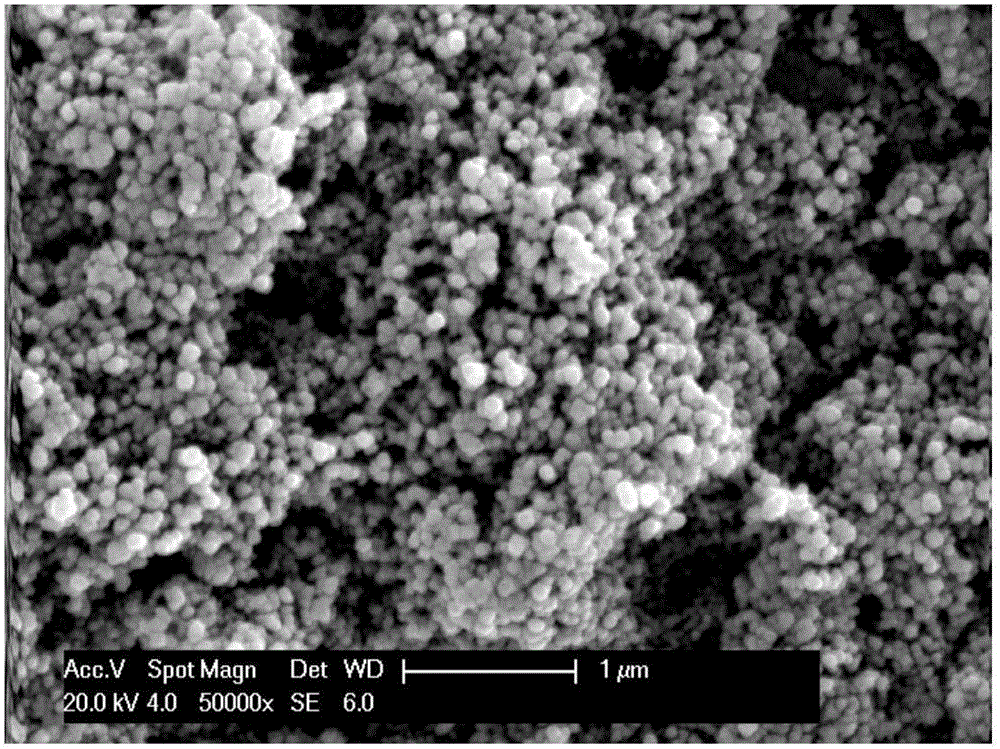

[0041] Under the condition of water bath at 20°C, add 50 parts of absolute ethanol, 1 part of ammonia water, and 5 parts of deionized water into the reaction kettle, stir at a speed of 1500r / min, and add 0.5 parts of chain-type nano-SiO2 dropwise. 2 Sol, after stirring for 30 minutes; add 0.5 parts of tetraethyl orthosilicate dropwise into the solution, and react for 10 minutes; finally, add 2 parts of fluorosilane dropwise into the solution, stir for 24 hours to obtain a superhydrophobic coating solution, and spray the solution On the cleaned copper substrate, drying can obtain nano-SiO 2 Superhydrophobic coating, surface morphology such as figure 1 As shown, nano-SiO 2 The superhydrophobic coating is evenly covered on the substrate, and the chains are intertwined with each other to form a nano-cavity structure. Nano-SiO 2 The particle size of the particles ...

Embodiment 2

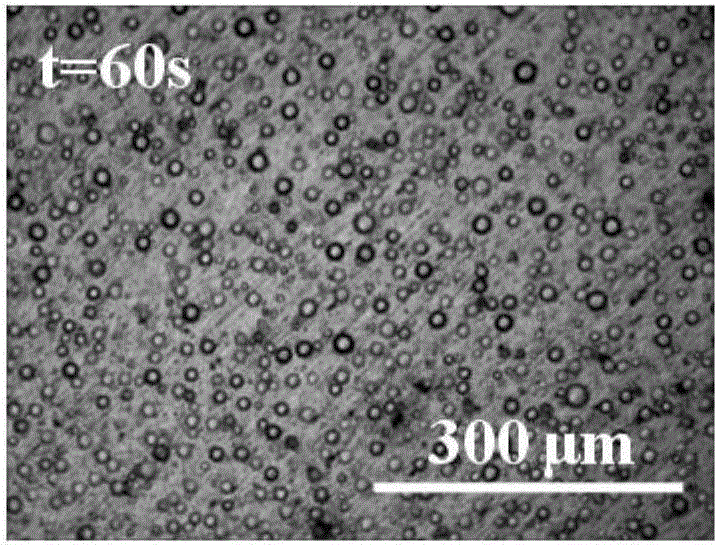

[0042] Example 2 Glass substrate brushing method to prepare hybrid superhydrophobic coating with glass beads

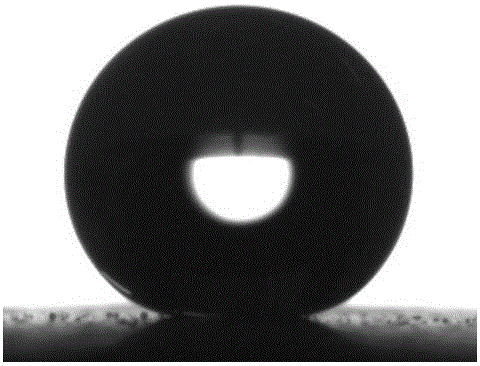

[0043] Under the condition of 30°C water bath, add 80 parts of absolute ethanol, 5 parts of ammonia water, and 7 parts of deionized water into the reaction kettle, stir at a speed of 1500r / min, and add 3 parts of chain nano-SiO2 dropwise. 2 sol, after stirring for 30 minutes; add 1 part of tetraethyl orthosilicate dropwise into the solution, and react for 30 minutes; Add microbeads (10 μm) superhydrophilic particles into the prepared superhydrophobic coating solution, continue to stir for more than 1 hour until the mixed solution is evenly dispersed, brush on the cleaned glass substrate, and obtain glass microbeads after drying Particle-hybrid superhydrophobic coatings, on which the static contact of water droplets is as image 3 As shown, the contact angle is 159.2°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com