Coating composition and usage thereof

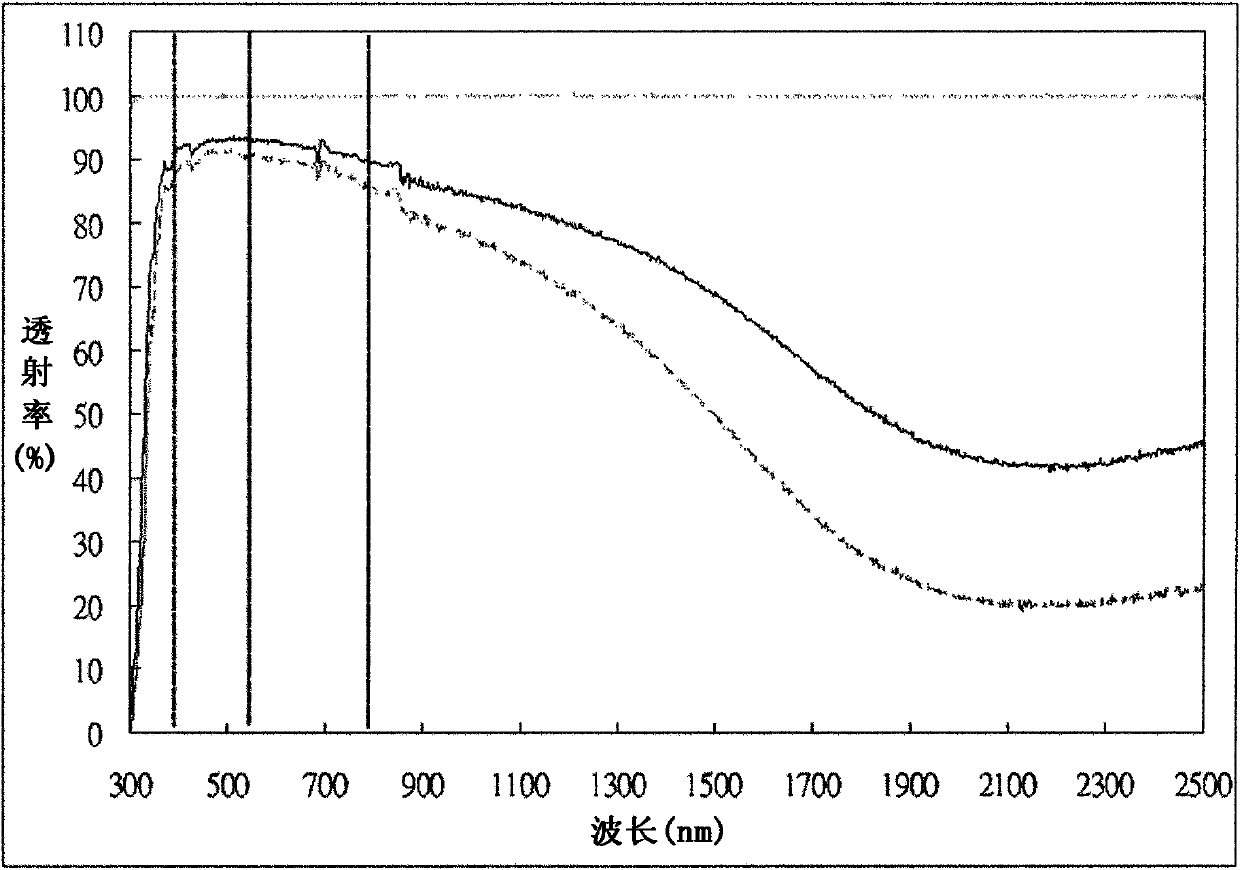

A composition and coating technology, applied in reflection/signal coatings, radiation-absorbing coatings, coatings, etc., can solve the problems of high manufacturing cost and complicated manufacturing process, and achieve the effect of simple manufacturing process and reduced transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the silicone resin used in the present invention is not particularly limited, and according to a preferred embodiment of the present invention, the silicone resin is formed by a sol-gel (sol gel) method. The raw material of the sol-gel method is about hundreds of nanometer-sized solid particles (usually inorganic metal salts) suspended in a liquid. In a typical sol-gel method, the reactants undergo a series of hydrolysis reactions and polymerization reactions to form a colloidal suspension, and the substances in it will condense into a new phase-a solution containing solid polymers, which is gel. The properties of the prepared sol-gel are affected by the type of raw material, type and concentration of catalyst, pH value, temperature, content of solvent, and type and concentration of alcohols and salts.

[0029] The coating composition of the present invention may add nanoscale inorganic particles as appropriate, and coat the surface of the phot...

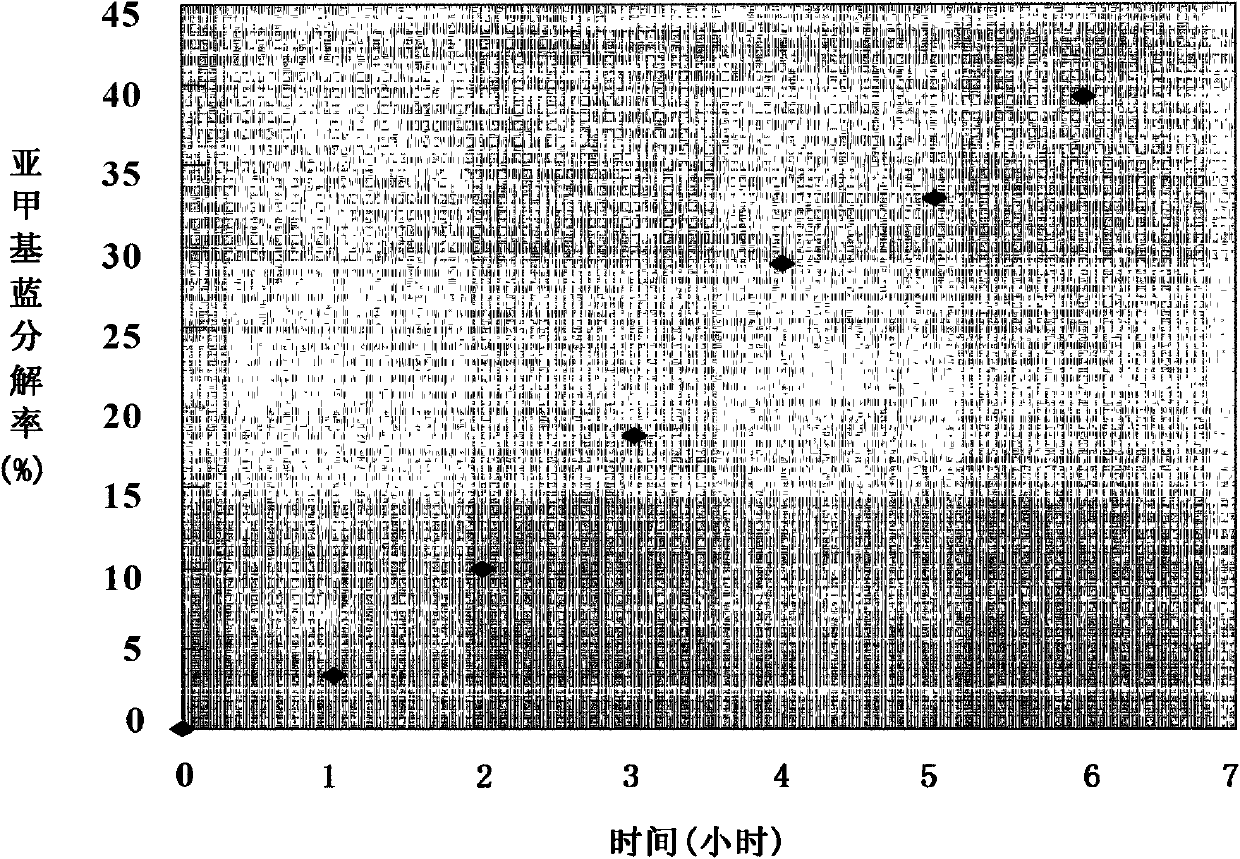

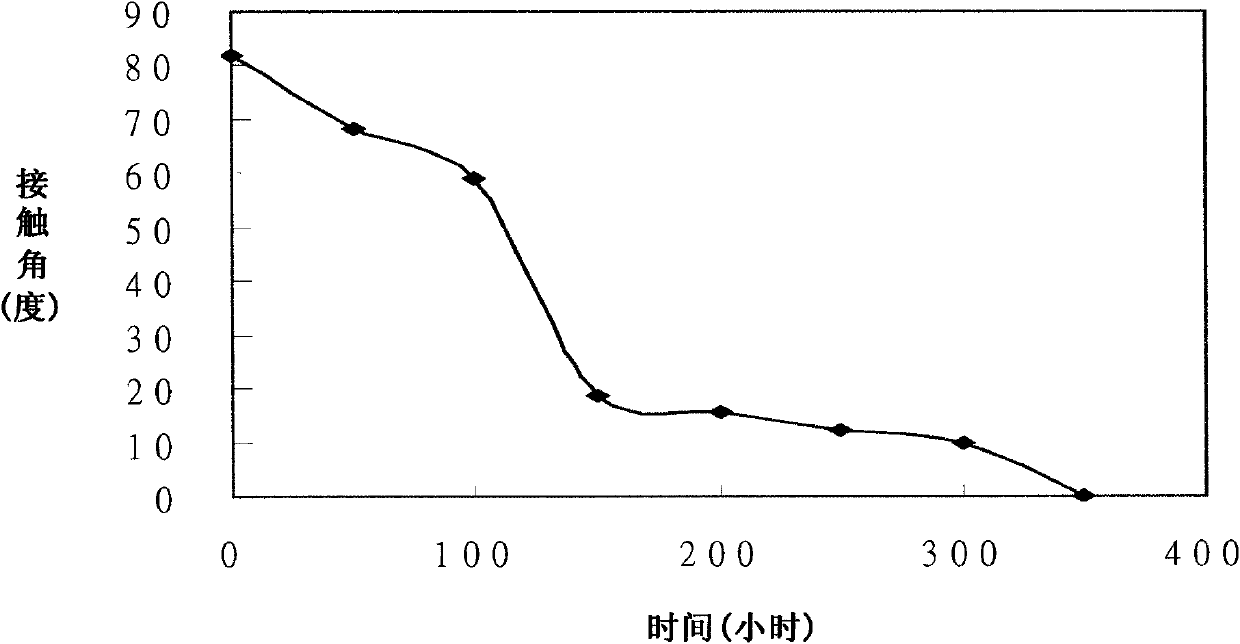

Embodiment 1

[0047] Take 200ml of 3.9M titanium tetrachloride aqueous solution, add water to dilute to a total volume of 2000ml, drop into 500ml (5M) of ammonia water, filter the white titanium dioxide hydrate produced, wash three times with 200ml of deionized water, remove excess water, Titanium hydroxide hydrate [TiO(OH) can be obtained in the form of white gel 2 】.

[0048] Add 100-150g of concentrated sulfuric acid (18M) to the above 250g of titanium hydroxide hydrate, stir for 30 minutes to obtain a transparent and clear titanium sulfate solution, put the titanium sulfate solution in the reaction kettle, and add 32.2g of SiO 2 Aqueous solution (20%) was stirred at room temperature for 4 hours, then heated to 100° C., and reacted for 2 hours. 100 g of ITO aqueous solution (10%) was added and stirred at normal temperature for 2 hours to obtain a mixture.

[0049] Add 600ml (5M) aqueous sodium hydroxide solution dropwise to the mixture and adjust the pH value to neutral. After filterin...

Embodiment 2

[0056] Take 3.9M 200ml titanium tetrachloride aqueous solution, add water to dilute to a total volume of 2000ml, add 500ml (5M) ammonia water dropwise, filter the white titanium dioxide hydrate produced, wash three times with 200ml deionized water, remove excess water, Titanium hydroxide hydrate [TiO(OH) can be obtained in the form of white gel 2 】.

[0057] Add 100-150g of concentrated sulfuric acid (18M) to the above 250g of titanium hydroxide hydrate, stir for 30 minutes to obtain a transparent and clear titanium sulfate solution, put the titanium sulfate solution in the reaction kettle, and add 32.2g of SiO 2 Aqueous solution (20%) was stirred at room temperature for 4 hours, then heated to 100° C., and reacted for 2 hours. 100 g of ATO aqueous solution (15%) was added and stirred at normal temperature for 2 hours to obtain a mixture.

[0058] In the mixture, drop 600ml (5M) sodium hydroxide aqueous solution and adjust the pH value to neutrality. After filtering, washing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com