Nanocrystalline metal oxide array with under-oil super-hydrophobicity and super-hydrophilicity reversible transition function and preparation method thereof

A nano-metal and nano-tube array technology, applied in nanotechnology, electrolytic inorganic material coating, electrolytic coatings, etc., can solve problems such as rare research, and achieve the effect of broadening the application scope of intelligent transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A specific embodiment of a nanometer metal oxide array with the reversible transformation function of superhydrophobic and superhydrophilic under oil is as follows:

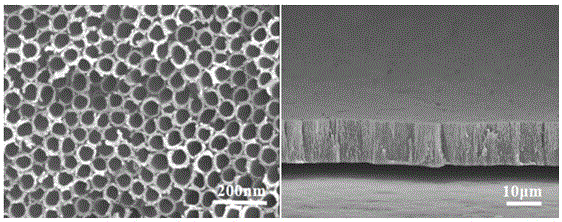

[0033] 1. Preparation of nano-metal oxide arrays: the ratio of ethylene glycol, ammonium fluoride and deionized water is 98vol%: 0.3wt%: 2vol% mixed electrolyte, the metal Ti sheet is used as the anode, and the platinum sheet is used as the cathode. The anodic oxidation voltage is 30V, and the oxidation time is 3h to obtain TiO 2 arrays of nanotubes, such as figure 1 shown.

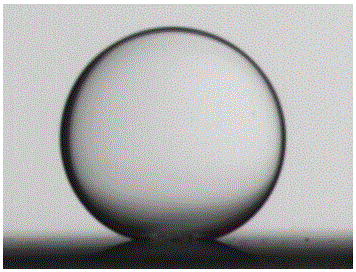

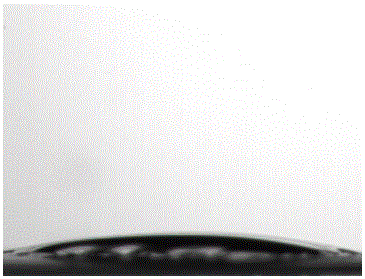

[0034] Second, the prepared TiO 2 The nanotube array was heat-treated at 120°C for 4 hours, and the static contact angle of water in the n-hexane oil phase was greater than 150°, with superhydrophobic properties, such as figure 2 shown.

[0035] In this step, in addition to n-hexane, the heat-treated TiO 2 The static contact angles of nanotube arrays in oil phases such as toluene, benzene, petroleum ether, cyclohexane, diesel oi...

Embodiment 2

[0045] A specific embodiment of a nanometer metal oxide array with the reversible transformation function of superhydrophobic and superhydrophilic under oil is as follows:

[0046] 1. Preparation of nano-metal oxide arrays: the ratio of ethylene glycol, ammonium fluoride and deionized water is 98vol%: 0.3wt%: 2vol% mixed electrolyte, the metal Ti sheet is used as the anode, and the platinum sheet is used as the cathode. Using secondary anodic oxidation, the oxidation voltage of each time is 50V, and the oxidation time is 1h to obtain TiO 2 arrays of nanotubes, such as figure 1 shown.

[0047] Second, the prepared TiO 2 The nanotube array was heat-treated at 350°C for 1 hour, and the static contact angle of water in the n-hexane oil phase was greater than 150°, with superhydrophobic properties, such as figure 2 shown.

[0048] In this step, in addition to n-hexane, the heat-treated TiO 2 The static contact angles of nanotube arrays in oil phases such as toluene, benzene, ...

Embodiment 3

[0058] A specific embodiment of a TiO2 nanotube array with sub-oil superhydrophobic and superhydrophilic reversible transformation functions is as follows:

[0059] 1. Preparation of nano-metal oxide arrays: Ammonium fluoride (0.3wt%) and ammonium sulfate mixed electrolyte was used, metal tungsten sheet was used as anode, platinum sheet was used as cathode, anodic oxidation voltage was 40V, and oxidation time was 2h. WO 3 array of nanotubes.

[0060] 2. The prepared WO 3 The nanotube arrays were heat-treated at 350°C for 1 hour, and the static contact angle of water in the n-hexane oil phase was greater than 150°, with superhydrophobic properties, such as figure 2 shown.

[0061] In this step, in addition to n-hexane, the heat-treated WO 3 The static contact angles of nanorod arrays in oil phases such as toluene, benzene, petroleum ether, cyclohexane, diesel oil, and n-heptane are all greater than 150°, realizing superhydrophobic properties in complex environments of diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com