Preparation method for super-hydrophobic and super-hydrophilic electrostatic spinning nanofiber composite membranes

A nanofiber and electrospinning technology, which is applied in fiber treatment, fiber type, textile and papermaking, etc., to achieve the effect of fine fiber diameter, simple preparation method and stable spinning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

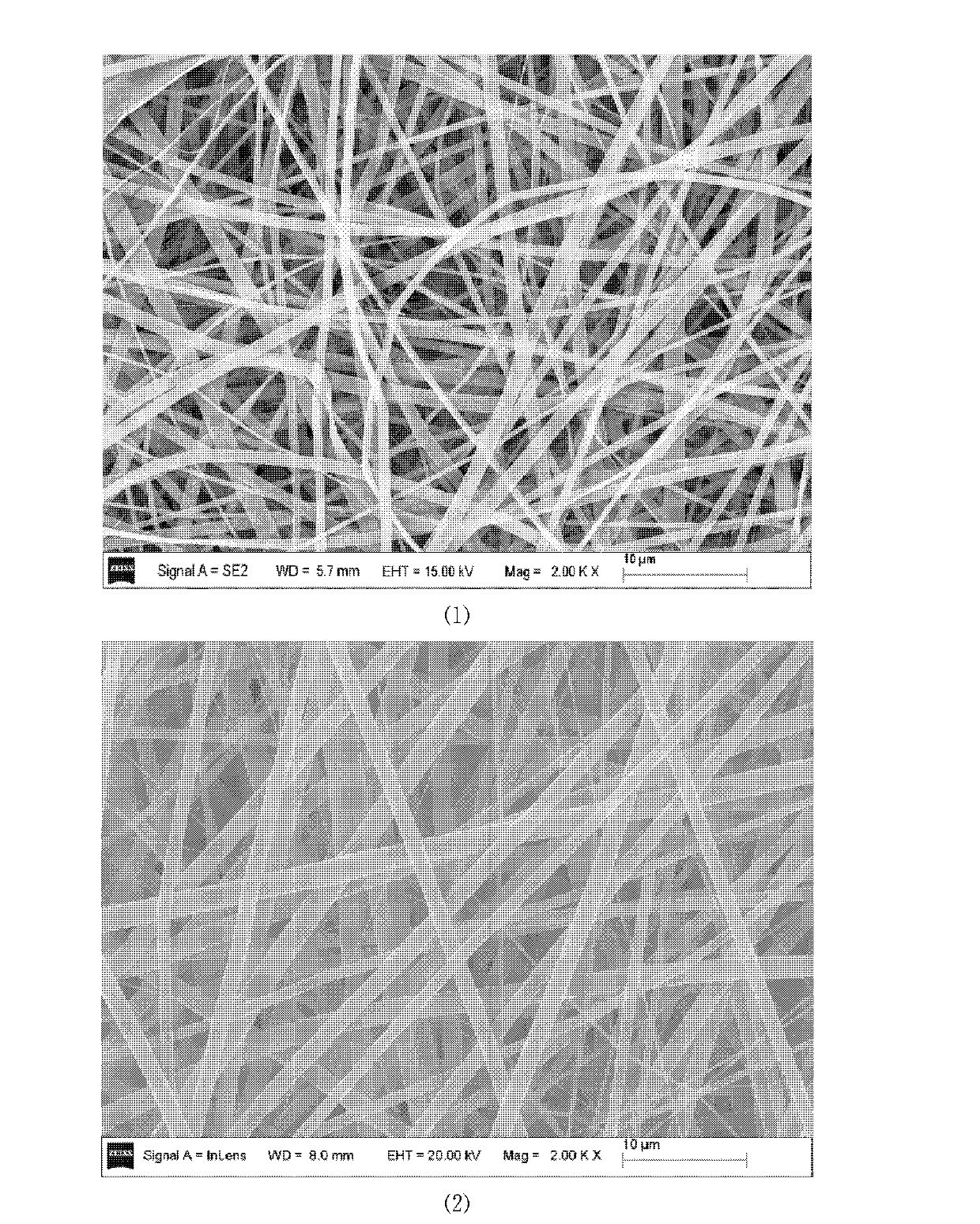

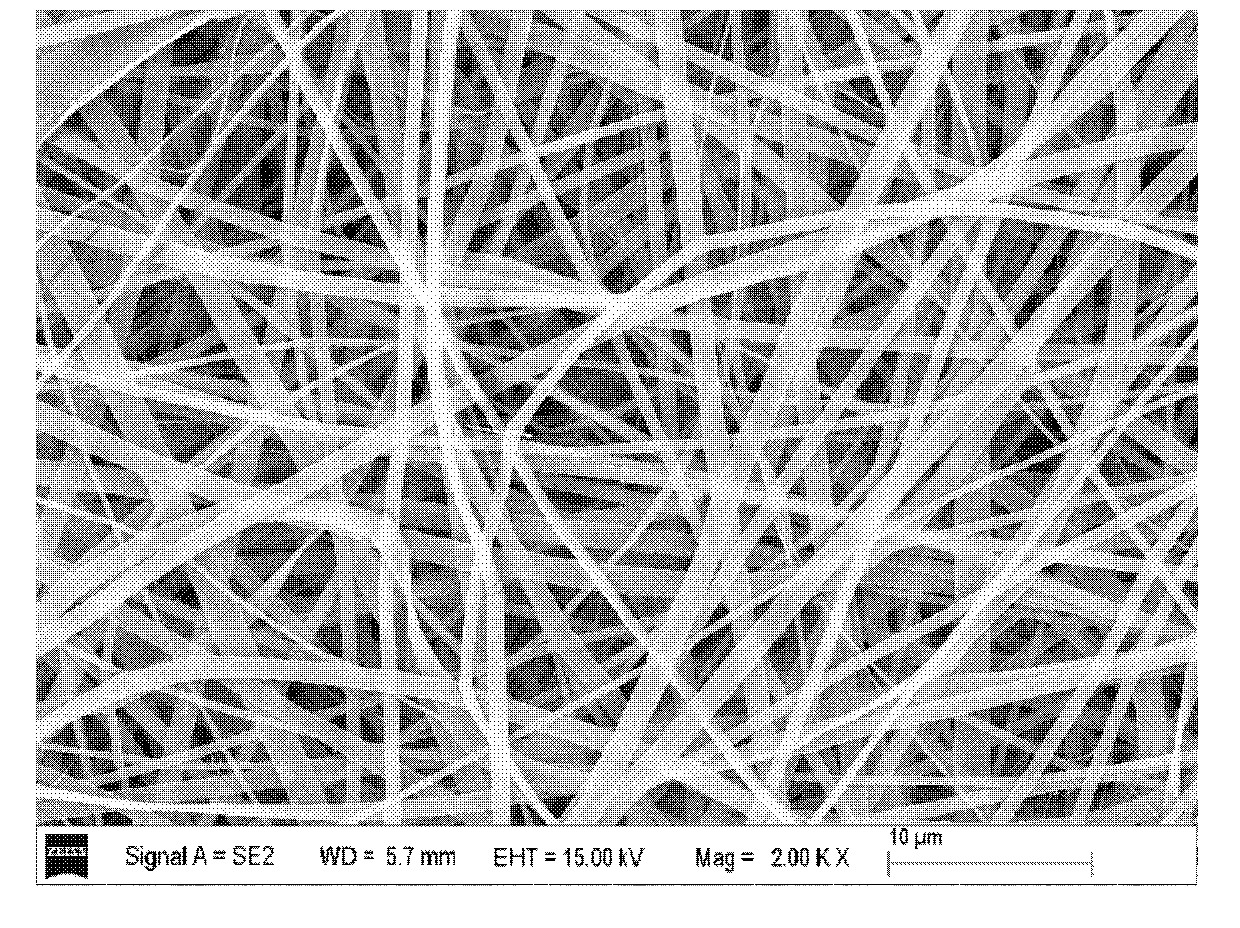

[0025] The preparation of superhydrophobic nanofiber composite film: polyethylene terephthalate PET / polyvinyl alcohol PVA mass ratio is 1 / 1, and the degree of alcoholysis of PVA is 88%, trifluoroacetic acid and dichloromethane 20mL (volume than 9 / 1) as a mixed solvent. A solution with a concentration of 15 wt % was prepared, stirred by magnetic force, dissolved at a temperature of 15° C., and dissolved for 20 hours, and left to stand to obtain a uniform and transparent mixed solution. Inject into the syringe of the electrospinning equipment, the spinning temperature is 30°C, the propulsion speed of the spinning solution is 0.002mm / min, the spinning voltage is 20kV, and the distance from the spinning needle to the receiving plate is 15cm, through the electrospinning instrument Prepare the film. Then the composite film was heat treated at a temperature of 120° C. for 5 hours. Then the composite film was dried in a vacuum oven for 24 hours at a temperature of 25°C. The treated...

Embodiment 2

[0029] The preparation of superhydrophobic nanofiber composite film: polyethylene terephthalate PET / polyvinyl alcohol PVA mass ratio is 1 / 2, and the degree of alcoholysis of PVA is 88%, trifluoroacetic acid and dichloromethane 20mL (volume than 9 / 1) as a mixed solvent. A solution with a concentration of 15 wt % was prepared, stirred by magnetic force, dissolved at a temperature of 15° C., and dissolved for 20 hours, and left to stand to obtain a uniform and transparent mixed solution. Inject into the syringe of the electrospinning equipment, the spinning temperature is 30°C, the propulsion speed of the spinning solution is 0.002mm / min, the spinning voltage is 20kV, and the distance from the spinning needle to the receiving plate is 15cm, through the electrospinning instrument Prepare the film. Then the composite film was heat treated at a temperature of 120° C. for 5 hours. Then the composite film was dried in a vacuum oven for 24 hours at a temperature of 25°C. The treated...

Embodiment 3

[0033]The preparation of superhydrophobic nanofiber composite film: polyethylene terephthalate PET / polyvinyl alcohol PVA mass ratio is 1 / 1, and the degree of alcoholysis of PVA is 88%, trifluoroacetic acid and dichloromethane 20mL (volume than 9 / 1) as a mixed solvent. A solution with a concentration of 12wt% was prepared, stirred by magnetic force, dissolved at a temperature of 15° C., dissolved for 20 hours, and left to stand to obtain a uniform and transparent mixed solution. Inject into the syringe of the electrospinning equipment, the spinning temperature is 30°C, the propulsion speed of the spinning solution is 0.002mm / min, the spinning voltage is 20kV, and the distance from the spinning needle to the receiving plate is 15cm, through the electrospinning instrument Prepare the film. Then the composite film was heat treated at a temperature of 120° C. for 5 hours. Then the composite film was dried in a vacuum oven for 24 hours at a temperature of 25°C. The treated compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com