Novel preparation method of nanometer self-cleaning glass

A nano self-cleaning and self-cleaning technology, applied in the field of functional materials, can solve the problems of low light transmittance and self-cleaning effect to be improved, achieve low refractive index, enhance superhydrophilicity and anti-fog performance, and have wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

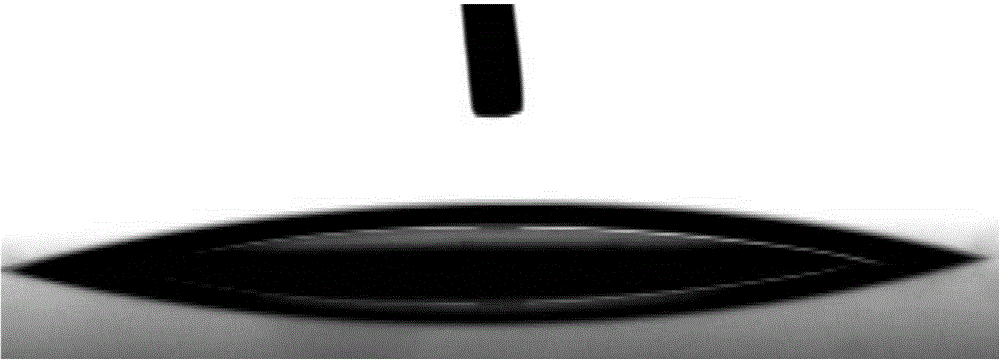

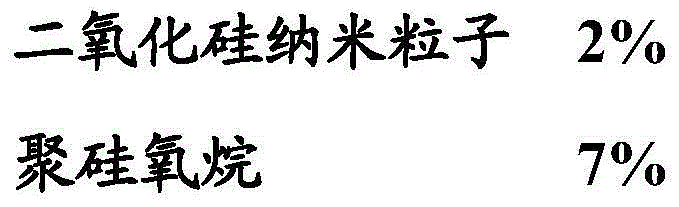

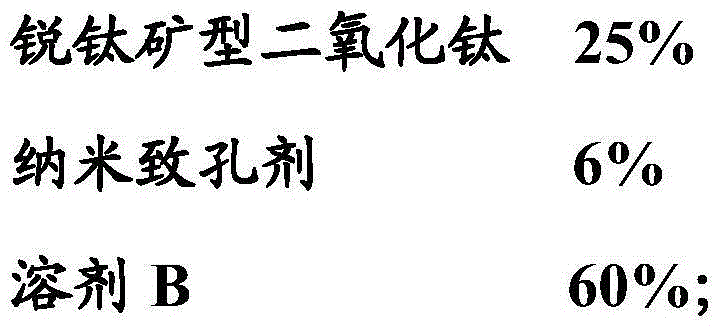

Embodiment 1

[0067] Use 400-mesh glass polishing powder to polish the glass surface with a rotating disk, then rinse the dirt and polishing powder on the glass surface with water, dry it naturally in a clean place, and spray the nano self-cleaning coating evenly on the glass surface with a spray gun (speed 1.2 m / s), stand at room temperature for 5 minutes, and a self-cleaning glass coated with a self-cleaning film can be obtained. The self-cleaning glass surface is sprayed with solvent A, left to stand, the solvent A in which the nano-porogen is dissolved is removed, and dried to form a nano-concave-convex structure on the film layer. Then the prepared self-cleaning glass was tempered at 700°C for 650 seconds. The treated self-cleaning glass not only maintained good superhydrophilic properties, but also the crystal form of titanium dioxide on the glass surface did not change. Strength and hardness are improved. After testing, the light transmittance of the glass is 95%, its contact angle ...

Embodiment 2

[0073] Two pieces of 5cm*5cm are taken from the self-cleaning glass (95% light transmittance) in Example 1, soaked in a methylene blue solution with a concentration of 1mmol / l for 1 hour, take it out, dry the back, and place it vertically in a dark place. After the methylene blue solution is naturally dried, put it under the ultraviolet lamp (45W) for half an hour, and then test the light transmittance of the glass to 95%, indicating that the methylene blue on the glass surface has been completely decomposed, and the self-cleaning glass has better light catalytic performance.

Embodiment 3

[0075] Continue to irradiate the self-cleaning glass with ultraviolet light for half an hour in Example 2 under a 500W ultraviolet lamp for 24 hours, observe its surface state, and there is no discoloration or pulverization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com