Method for preparing self-cleaning antifogging coating film

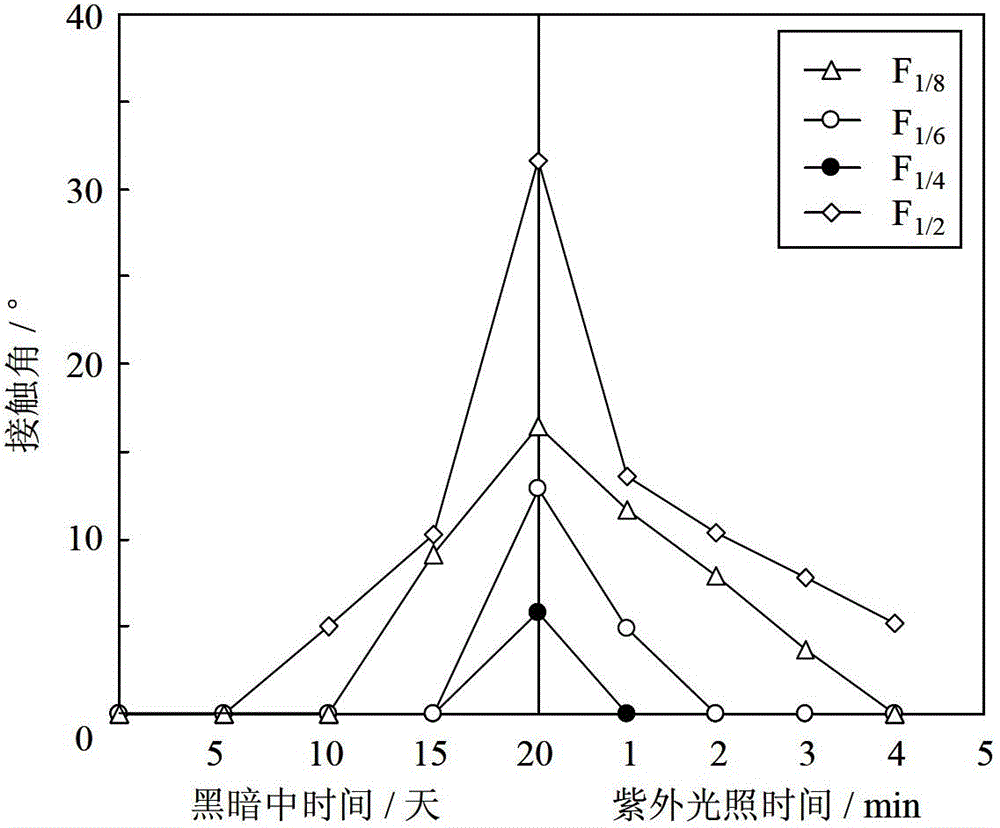

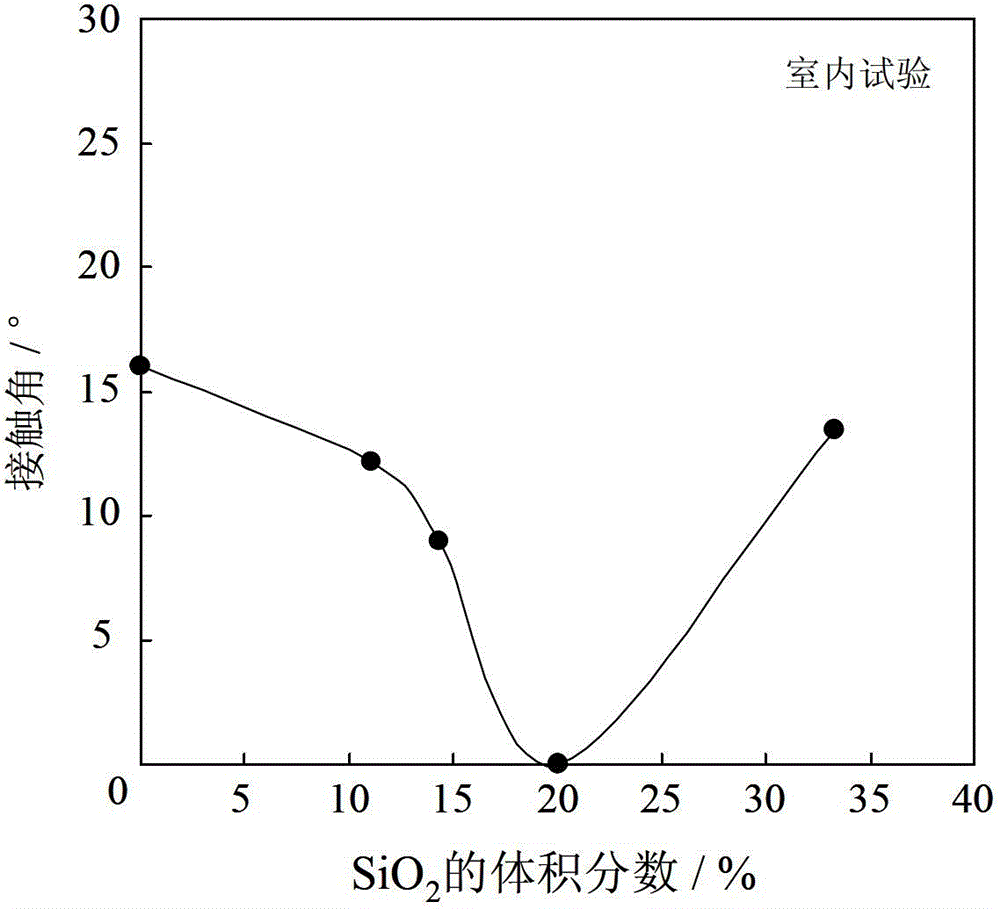

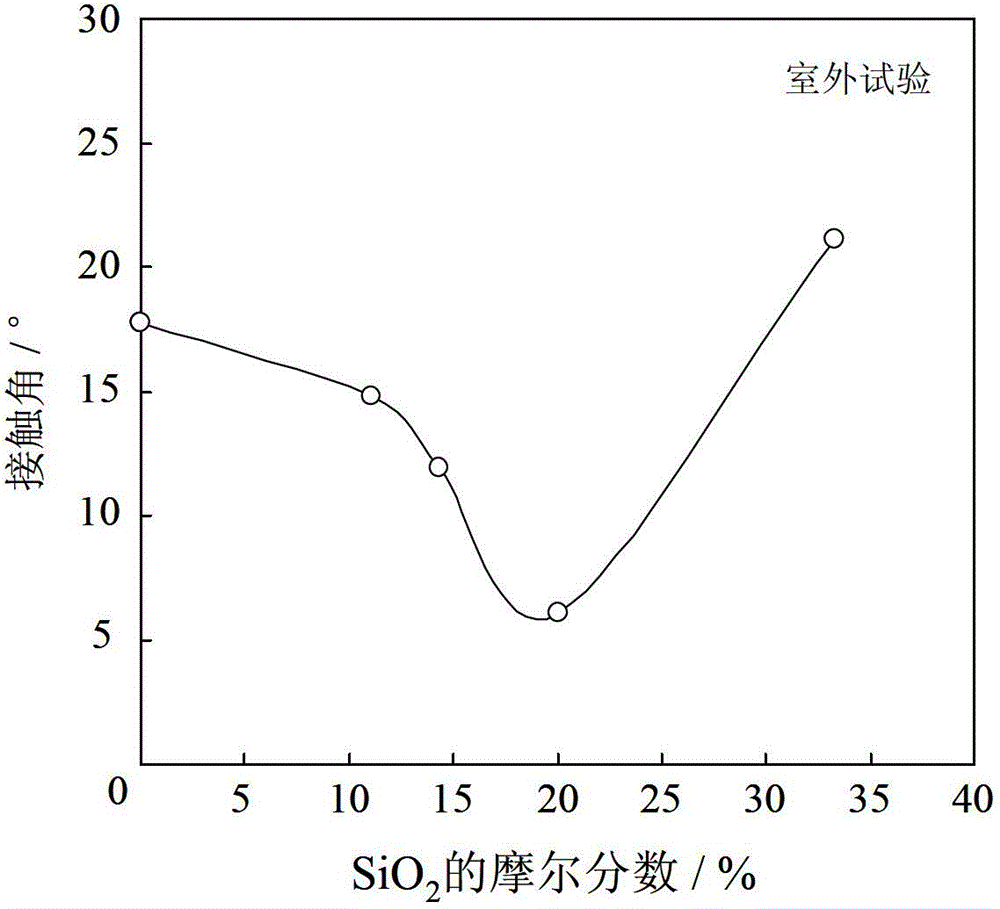

An anti-fog coating and self-cleaning technology, applied in the field of thin films, can solve problems such as pollution, achieve the effects of reducing apparent contact angle, improving water wetting performance, and good superhydrophilic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Nano-TiO 2 Preparation of granules:

[0038] (1) Mix 5 mL of n-butyl titanate (TBOT) with 2 mL of acetylacetone (ACAC), stir for 10 min, add 2 mL of cyclohexane, and continue stirring for 30 min to obtain solution A.

[0039] (2) Prepare 40 mL of double-distilled aqueous solution B of 800 mg / L dodecylbenzenesulfonic acid.

[0040](3) Add solution B to solution A under magnetic stirring, and keep stirring for 20 min to obtain the emulsion of TBOT.

[0041] (4) Add 40 mL of absolute ethanol to the formed emulsion and continue stirring for 30 min to obtain a clear and transparent microemulsion.

[0042] (5) Transfer the microemulsion to a reactor with a polytetrafluoroethylene inner cup, and react at a temperature of 150 °C for 24 h to obtain TiO 2 suspension.

[0043] 2. TiO 2 Film preparation:

[0044] (1) The glass substrate will be washed successively with ethanol, acetone and water, and then dried at 100°C for 30 min.

[0045] (2) Dip the dried glass subst...

Embodiment 2

[0056] 1. Nano-TiO 2 Preparation of granules:

[0057] (1) Mix 5 mL of n-butyl titanate (TBOT) with 2 mL of acetylacetone (ACAC), stir for 10 min, add 2 mL of cyclohexane, and continue stirring for 30 min to obtain solution A.

[0058] (2) Prepare 40 mL of double-distilled aqueous solution B of 72 mg / L dodecylbenzenesulfonic acid.

[0059] (3) Add solution B to solution A under magnetic stirring, and keep stirring for 20 min to obtain the emulsion of TBOT.

[0060] (4) Add 40 mL of absolute ethanol to the formed emulsion and continue stirring for 30 min to obtain a clear and transparent microemulsion.

[0061] (5) Transfer the microemulsion to a reactor with a polytetrafluoroethylene inner cup, and react at a temperature of 150 °C for 24 h to obtain TiO 2 suspension.

[0062] 2. SiO 2 Sol configuration:

[0063] (1) Add 5 mL ethyl orthosilicate to 75 mL ethanol, and stir magnetically at room temperature for 2 min to obtain ethyl orthosilicate solution C.

[0064] (2) ...

Embodiment 3

[0080] 1. Nano-TiO 2 Preparation of granules:

[0081] (1) Mix 5 mL of n-butyl titanate (TBOT) with 2 mL of acetylacetone (ACAC), stir for 10 min, add 2 mL of cyclohexane, and continue stirring for 30 min to obtain solution A.

[0082] (2) Prepare 40 mL of double-distilled aqueous solution B of 72 mg / L dodecylbenzenesulfonic acid.

[0083] (3) Add solution B to solution A under magnetic stirring, and keep stirring for 20 min to obtain the emulsion of TBOT.

[0084] (4) Add 40 mL of absolute ethanol to the formed emulsion and continue stirring for 30 min to obtain a clear and transparent microemulsion.

[0085] (5) Transfer the microemulsion to a reactor with a polytetrafluoroethylene inner cup, and react at a temperature of 150 °C for 24 h to obtain TiO 2 suspension.

[0086] 2. SiO 2 Sol configuration:

[0087] (1) Add 5 mL ethyl orthosilicate to 75 mL ethanol, and stir magnetically at room temperature for 2 min to obtain ethyl orthosilicate solution C.

[0088] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com