Preparation method of compound material with super-hydrophilic polyvinylidene fluoride@dopamine@silicon dioxide

A technology of polyvinylidene fluoride and polyvinylidene fluoride membrane, which is applied in the field of preparation of superhydrophilic polyvinylidene fluoride@dopamine@silicon dioxide composite materials, which can solve problems such as blocking sunlight, low separation efficiency, and endangering human health , to achieve the effect of improving hydrophilic performance, improving rough structure and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

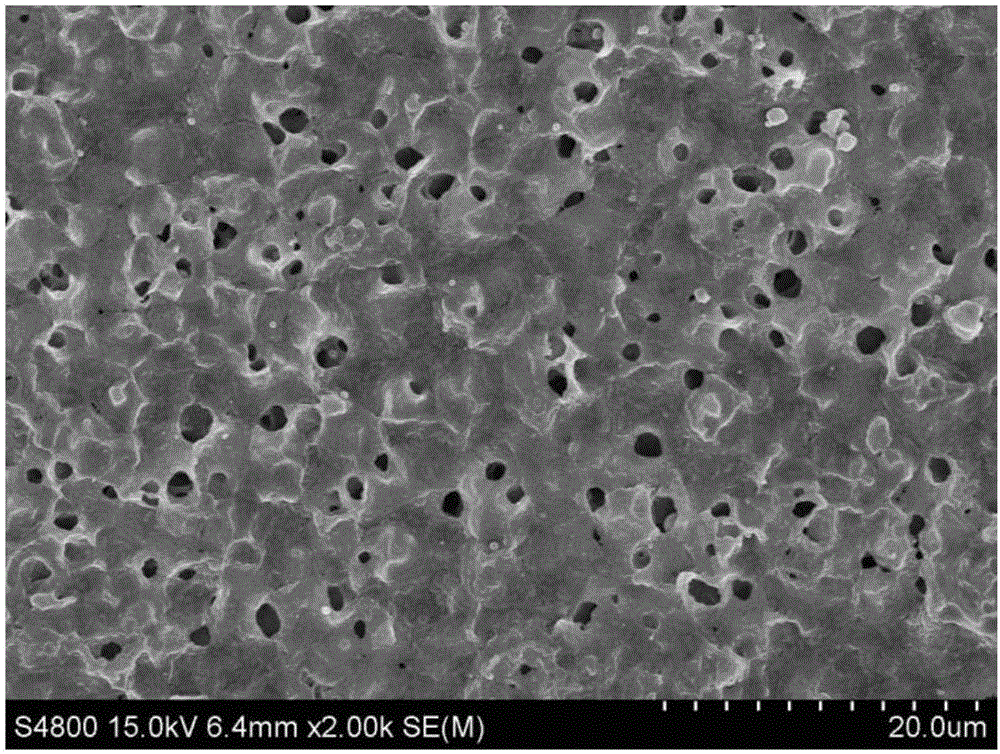

Embodiment 1

[0027] (1) Preparation of polyvinylidene fluoride film: Dissolve 3g of polyvinylidene fluoride powder in 40mL of N-methylpyrrolidone, stir mechanically in a water bath at 40°C for 12 hours, and then stand in a water bath at 40°C for 12 hours to obtain polyvinylidene fluoride For casting solution, apply the casting solution on a glass plate at a uniform speed with a scraper, and then place it in a coagulation bath (deionized water). solvent, washed with distilled water and dried at 40°C.

[0028] (2) Preparation of polyvinylidene fluoride@dopamine: Add 200 mg of dopamine to 100 mL of 10 mM Tris-HCl solution and mix evenly in the solution. Take a polyvinylidene fluoride membrane with a size of 3 × 3 cm and immerse it in a mixed solution with a pH of 8.5 and room temperature. Shake in a shaker for 12 hours (80-120 rpm) under certain conditions, wash with water and dry at 40°C.

[0029] (3) Preparation of superhydrophilic polyvinylidene fluoride@dopamine@silica composite film: 0....

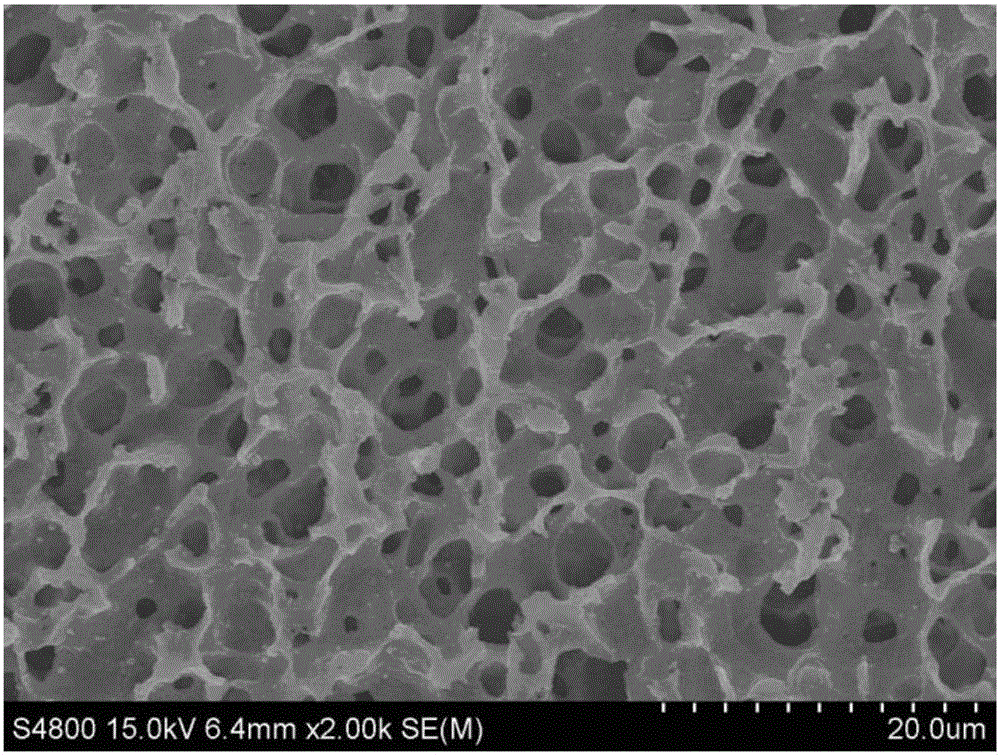

Embodiment 2

[0036] (1) Preparation of polyvinylidene fluoride film: Dissolve 4.5g of polyvinylidene fluoride powder in 40mL of N-methylpyrrolidone, mechanically stir in a water bath at 60°C for 8 hours, and then stand in a water bath at 60°C for 8 hours to obtain polyvinylidene fluoride Ethylene casting solution, apply the casting solution on the glass plate at a uniform speed with a scraper, and then place it in a coagulation bath (distilled water). solvent, washed with distilled water and dried at 40°C.

[0037](2) Preparation of polyvinylidene fluoride@dopamine: In 100mL10mM Tris-HCl solution, add 150mg dopamine in the solution and mix evenly, take a polyvinylidene fluoride film with a size of 3×3cm and immerse it in the mixed solution at room temperature of pH=8.5 Shake in a lower shaker for 8 hours (80-120 rpm), wash with water and dry at 40°C.

[0038] (3) Preparation of superhydrophilic polyvinylidene fluoride@dopamine@silica composite film: 0.2mol NH 3 , 0.27mol ethanol, 25mL de...

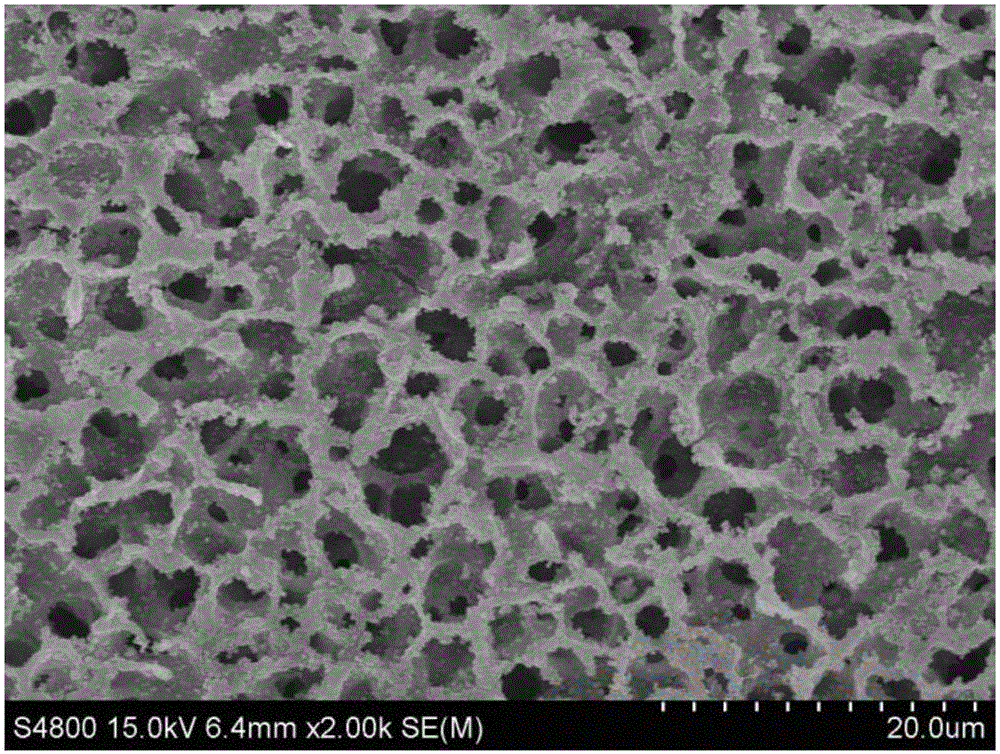

Embodiment 3

[0040] (1) Preparation of polyvinylidene fluoride film: Dissolve 6g of polyvinylidene fluoride powder in 40mL of N-methylpyrrolidone, mechanically stir in a water bath at 80°C for 6h, then stand in a water bath at 80°C for 6h to obtain polyvinylidene fluoride For casting solution, apply the casting solution on a glass plate at a uniform speed with a scraper, and then place it in a coagulation bath (deionized water). solvent, washed with distilled water and dried at 40°C.

[0041] (2) Preparation of polyvinylidene fluoride@dopamine: In 100mL10mM Tris-HCl solution, add 2mg / mL dopamine in the solution and mix evenly, take a polyvinylidene fluoride membrane with a size of 3×3cm and immerse it in the mixed solution pH=8.5 room temperature Shake in a shaker for 6 hours (80-120 rpm) under certain conditions, wash with water and dry at 40°C.

[0042] (3) Preparation of superhydrophilic polyvinylidene fluoride@dopamine@silica composite film: 0.2mol NH 3 , 0.27mol ethanol, 25mL deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com