Method for preparing super-hydrophilic polyvinylidene fluoride membrane

A polyvinylidene fluoride membrane, super-hydrophilic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of nano-TiO easy to fall off, unstable super-hydrophilic performance, weak adsorption force, etc. problems, to achieve the effects of easy operation and implementation, improved mechanical properties and heat resistance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The steps of the preparation method of superhydrophilic polyvinylidene fluoride membrane are as follows:

[0018] 1) Polyvinylidene fluoride with a mass percentage of 10% to 20%, a copolymer containing maleic anhydride with a mass percentage of 2 to 4%, a pore size regulator with a mass percentage of 1 to 2% and a mass percentage of 74% ~87% of the solvent is mixed and stirred evenly under the protection of an inert gas, and the film-forming liquid is obtained after vacuum defoaming;

[0019] 2) Use ethanol as the coagulation bath to obtain the polyvinylidene fluoride film through solution phase inversion;

[0020] 3) Soak the polyvinylidene fluoride membrane in the aminosilane solution for 4 to 6 days, take it out and dry it to obtain a superhydrophilic polyvinylidene fluoride membrane.

[0021] The described copolymer containing maleic anhydride is styrene / maleic anhydride copolymer, methyl methacrylate / maleic anhydride or vinyl acetate / maleic anhydride copolymer. T...

Embodiment 1

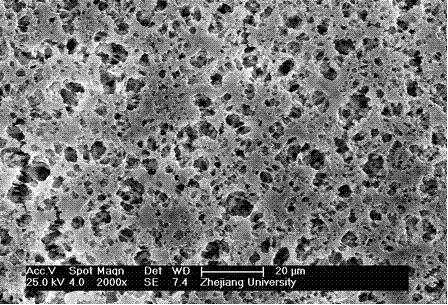

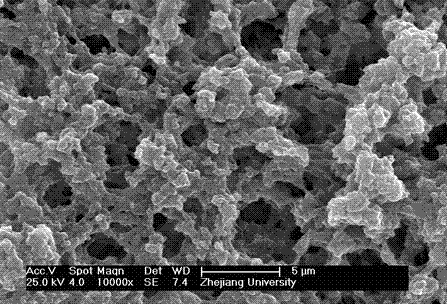

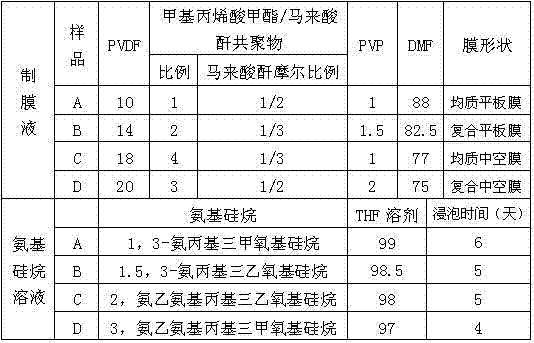

[0026] Example 1. The preparation of PVDF and styrene / maleic anhydride copolymer blended super-hydrophilic membrane, the specific steps are: 1) the mass percentage is 10% PVDF, and the mass percentage is 2% styrene / maleic anhydride The copolymer, the pore size regulator PVP with a mass percentage of 1% and the solvent DMF with a mass percentage of 87% were mixed and stirred evenly under the protection of an inert gas, and the film-forming liquid was obtained after vacuum defoaming; 2) the obtained in 1) 3) Immerse the PVDF membrane obtained in 2) in the tetrahydrofuran (THF) solution of aminosilane for 4-6 days, take out Dry to obtain superhydrophilic PVDF membrane. Table 1 shows the components, mass content and film types in the film-making solution and aminosilane solution.

[0027] Table 1

[0028]

Embodiment 2

[0029] Embodiment 2. The preparation of PVDF and methyl methacrylate / maleic anhydride copolymer blending super-hydrophilic membrane, concrete steps are with embodiment 1. Table 2 shows the components, mass content and film types in the film-making solution and aminosilane solution.

[0030] Table 2

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com