Application of super hydrophilicity and/or super lipophilicity nano pore material

A nanoporous material and super-hydrophilic technology, which is applied in the field of superhydrophilic and/or super-lipophilic nanoporous materials to achieve the effects of improved affinity properties, fast spreading speed, and excellent filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

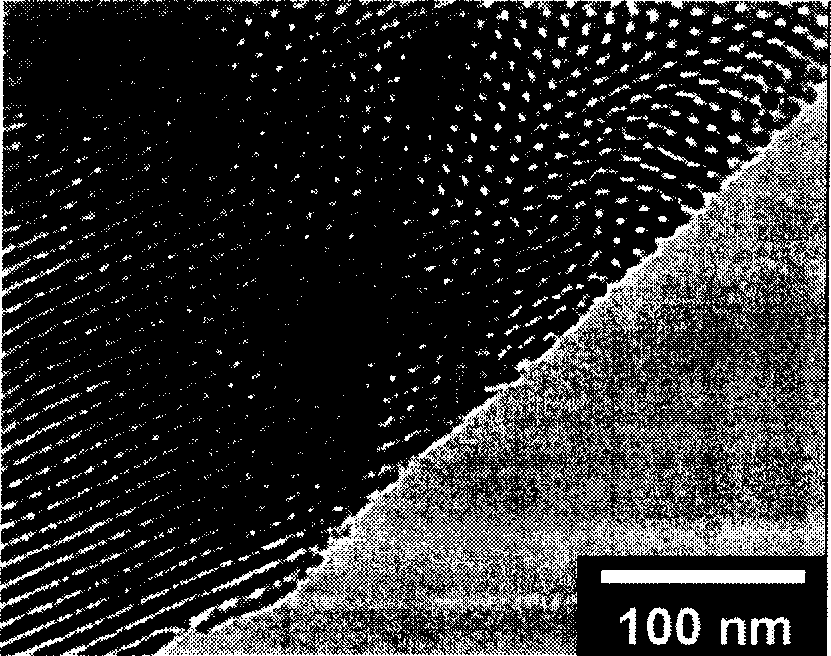

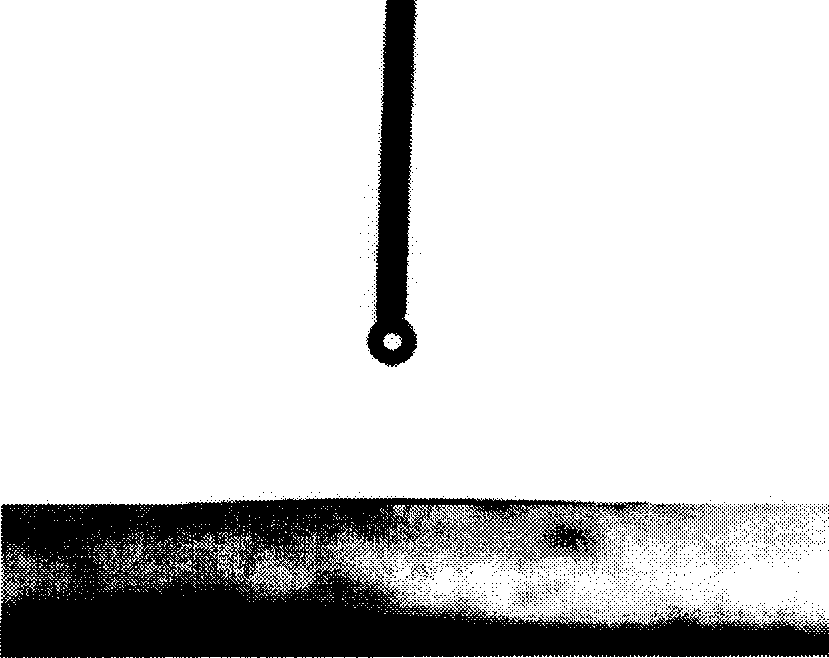

[0040] Example 1: Use of superhydrophilic and / or superlipophilic nanoporous silica in anti-fog aspects. 208 parts by weight of tetraethyl orthosilicate, 260 parts by weight of ethanol, 36 parts by weight of water, and 0.63 parts by weight of nitric acid , block copolymer Pluronic-127{PEO 20 -PPO 106 -PEO 20}84 parts by weight were mixed evenly, and refluxed at 60° C. for 90 minutes under electromagnetic stirring to obtain a colorless and transparent silica sol. Apply the obtained sol to glass, pottery, stone or metal at a lifting speed of 30 cm / min to form a thin film by dipping into the pulling coating method. After drying at room temperature, the obtained film material was immersed in ethanol for 2 hours to dissolve the block copolymer to obtain a nanoporous material with a superhydrophilic and / or superlipophilic surface. The results of transmission electron microscopy show that the nanopores are arranged in a hexagonal manner, and the size of the pores is about 10 nanome...

Embodiment 2

[0041] Example 2: Use of superhydrophilic and / or superoleophilic nanoporous silica composites in self-cleaning

[0042] In the silica sol obtained in Example 1, add 10 parts by weight of titanium dioxide nanoparticles P25 or zinc oxide nanoparticles (average particle diameter 20 nanometers), and obtain a composite sol after ultrasonic dispersion is uniform. The sol is coated on a glass sheet to obtain a nanoporous silica composite material with self-cleaning function. The static contact angles of water and hexadecane on its surface are 4.8° and 0°, respectively, indicating superamphiphilic properties. The coating has the properties of decomposing organic matter, anti-fouling, anti-fog, sterilization and deodorization due to photocatalysis under light irradiation, and has self-cleaning properties. It can be used to manufacture medical materials, wall tiles, glass, etc. with sterilization and disinfection functions, and has the effect of purifying air.

Embodiment 3

[0043] Example 3: Use of superhydrophilic and / or superoleophilic nanoporous titanium dioxide in self-cleaning

[0044] 250 parts by weight of tetrabutyl titanate, 450 parts by weight of ethanol, 18 parts by weight of nitric acid, and 75 parts by weight of glucose were uniformly mixed, and refluxed at 60° C. for 2 hours under electromagnetic stirring to obtain a colorless and transparent titanium dioxide sol. The resulting sol was coated on a flat glass slide at a speed of 2500 rpm by spin coating to form a thin film. After drying at room temperature, place the obtained film material in a sintering furnace, and ventilate the air, heat up to 500°C at a rate of 2°C / min and burn for 2 hours to remove glucose and obtain self-cleaning superhydrophilic, super Lipophilic nanoporous titanium dioxide. Transmission electron microscope results show that the nanopores are arranged in a hexagonal manner, and the size of the pores is about 2 nanometers. The static contact angles of water a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com