Preparation method of anticorrosive coating capable of self-repairing rapidly at room temperature

An anti-corrosion coating and self-healing technology, applied in anti-corrosion coatings, microsphere preparation, epoxy resin coatings, etc., can solve problems such as unsatisfactory repair effect and weak micro-crack capillary siphon effect, and increase repair efficiency and production cost. Low, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

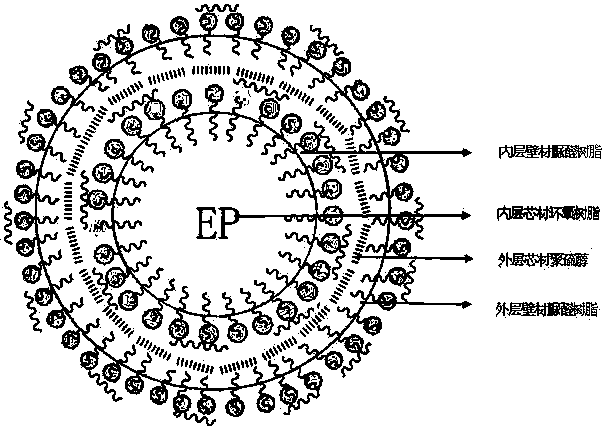

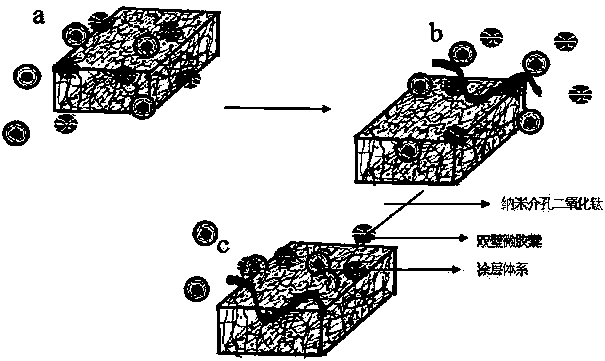

[0022] The preparation process of the method of the present invention: Weigh 1-10 parts of nanometer mesoporous silica particles, add 1-5 parts of dispersant and mix evenly; add 5-10 parts of solvent, 0-10 parts of dibutyl phthalate , in a mixture of 60-100 parts of film formers; after grinding and dispersing for 30-90 minutes at normal temperature and pressure, add 1-10 parts of double-walled microcapsules to make a paint mother liquor; the prepared mother liquor is used in the same way as ordinary paint , the mother liquor is mixed with the curing agent, and brushed to make a coating. The self-healing microcapsules with double-wall sandwich structure are made of repairing agent (epoxy resin and its diluent) as the inner layer core material, urea-formaldehyde resin as the inner layer wall material, polythiol type curing agent as the outer layer core material, and urea-formaldehyde resin as the outer layer core material. Outer wall material. The film former is bisphenol A or ...

Embodiment 1

[0026] (1) Using in-situ polymerization to prepare single-wall microcapsules coated with epoxy resin by urea-formaldehyde resin by a two-step synthesis method;

[0027] (2) Synthesis of self-healing microcapsules with double-wall sandwich structure: Mix epoxy resin room temperature rapid curing agent polythiol type curing agent with single-coated microcapsules at a mass ratio of 1:3~1 in a small beaker. Add 80ml of deionized water, 0.45g of curing agent resorcinol, 0.45g of pH regulator ammonium chloride, 1~2 drops of defoamer n-octanol, a certain quality of emulsifier and urea into the diluted epoxy resin disperse for about 30 minutes at an emulsification speed of 6000~10000r / min to form a stable oil-in-water (O / W) emulsion, transfer the emulsion to a three-necked bottle, add a certain amount of formaldehyde, and adjust the initial pH of the system with dilute hydrochloric acid The value is about 3, the temperature of the water bath is raised slowly, and the temperature o...

Embodiment 2

[0029] Coating formula: (weight percentage meter)

[0030] Nano-mesoporous silica particles: 5 parts (particle size is 60~80nm);

[0031] Dispersant: 0.5 parts;

[0032] Dibutyl phthalate: 5 parts;

[0033] Xylene: 20 parts;

[0034] 10 parts of double-walled microcapsules;

[0035] Epoxy (using E-44): balance.

[0036] Its dispersant composition (weight percent):

[0037] Sodium oleate 10%;

[0038] Disperbyk-160 80%;

[0039] Toluene 10%;

[0040] The dispersant is prepared by first mixing sodium oleate and toluene at 25 °C and 1 atm to fully dissolve sodium oleate in toluene, then slowly adding the Disperbyk-160 component and mixing evenly.

[0041] Coating preparation method:

[0042] Weigh 5 parts of nanometer mesoporous silica powder, mix it evenly with the dispersant, add it to the epoxy resin mixed with other additives, grind and disperse for 30 minutes at normal temperature and pressure, and add 10 parts The double-walled microcapsules were used to prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com