Method for preparing hydrophilic/oleophobic oil-water separation stainless steel net films

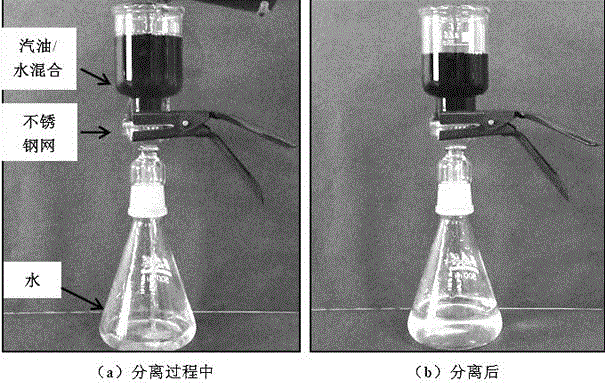

An oil-water separation, stainless steel mesh technology, applied in separation methods, liquid separation, semi-permeable membrane separation, etc., can solve the problems of membrane surface and pore fouling, blocking water flux, low separation efficiency, poor stability, etc. High separation effect, adjustable aperture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

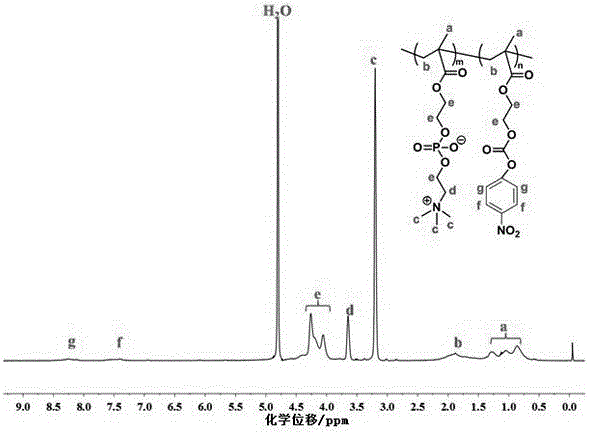

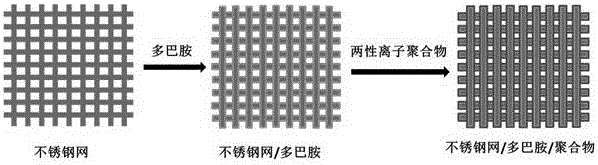

[0031] (2) Preparation of zwitterionic polymers containing active esters;

[0032] (3) With stainless steel mesh as the substrate and polydopamine as the mediating layer, the active ester group of the zwitterionic polymer and the amino group of polydopamine undergo amidation reaction to construct a hydrophilic / oleophobic oil-water separation membrane.

Embodiment 1

[0034] Example 1 Construction of polydopamine mediation layer by spraying method

[0035] (1) Use acetone and absolute ethanol to ultrasonically clean the 1000-mesh (pore size 13 μm) stainless steel mesh to be modified in an ultrasonic cleaner for 15 minutes, then ultrasonically clean it with 5% sodium hydroxide solution for 15 minutes, and then use Rinse with deionized water, dry with nitrogen gas for later use;

[0036] (2) Under the condition of pH=6.8, prepare a dopamine solution containing ammonium persulfate, the concentration of ammonium persulfate is 2 mg / mL, and the concentration of dopamine is 4 mg / mL;

[0037] (3) Evenly spray the prepared dopamine solution on the surface of the stainless steel mesh to be modified;

[0038] (4) Place the sprayed stainless steel mesh in a water vapor atmosphere at a heating temperature of 120°C and a heating time of 4 h to speed up the construction of the polydopamine-mediated layer;

[0039] (5) Rinse the surface of the stainless ...

Embodiment 2

[0040] Example 2 Construction of polydopamine mediation layer by dip coating method

[0041] (1) Clean the 1000-mesh (pore size 13 μm) stainless steel mesh to be modified with acetone and absolute ethanol in an ultrasonic cleaner for 15 minutes, then ultrasonically clean it with 5% sodium hydroxide solution for 15 minutes, and then Rinse with deionized water and dry with nitrogen gas for later use;

[0042] (2) Under the condition of pH=7.8, prepare a dopamine solution containing ammonium persulfate, the concentration of ammonium persulfate is 1 mg / mL, and the concentration of dopamine is 2 mg / mL;

[0043] (3) Immerse the stainless steel mesh in the above-prepared dopamine solution for 4 h;

[0044] (4) After 4 hours, the stainless steel mesh was taken out of the dopamine solution and heated at 140°C for 1 hour;

[0045] (5) Rinse the surface of the stainless steel mesh and the polydopamine that is not firmly combined with the mesh with distilled water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com