Superhydrophilic/underwater superoleophobic coating material and preparation method thereof

An underwater superoleophobic, coating material technology, applied in antifouling/underwater coatings, coatings, biocide-containing paints, etc., can solve the problem of poor water resistance, low coating transparency, poor mechanical properties, etc. problems, to achieve the effect of good mechanical properties of the coating, high transparency of the coating, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

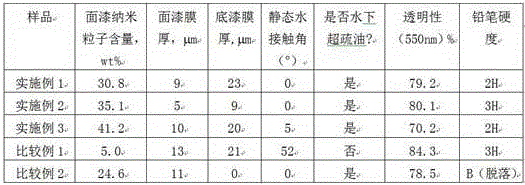

Examples

Embodiment 1

[0034] Dissolve 5g of polyvinyl alcohol (PVA) 1788 with a degree of alcoholysis of 88% with 50g of hot water, and add 2.5g of SiO with a particle size of 12nm 2 , made of PVA / SiO 2 / 33% dispersion. 2g of hydroxyacrylic resin and 0.2g of fully etherified melamine were dissolved in 5g of butyl acetate, and 0.01g of p-toluenesulfonic acid was added. The solution was rolled onto a standard glass slide with a 120 μm wire bar. After the solvent is fully volatilized and the coating film loses its fluidity, a layer of PVA / SiO is coated on it with a 120 μm wire rod. 2 / 33% dispersion. After the upper liquid film is dried at room temperature, the uncrosslinked double-layer coating is placed in an oven at 70° C. for 0.5-5 hours. After taking it out, cool it to room temperature, put it into 5 vol% formaldehyde aqueous solution (adjust the pH to 2 with sulfuric acid), soak and solidify for 0.1-3 hours, rinse and dry. Finally, the double-layer coating is heat-treated at 120° C. for 0.1...

Embodiment 2

[0036] Dissolve 5g of polyvinyl alcohol Mowiol 117 with a degree of alcoholysis of 98% in 50g of hot water, and add 5.0g of SiO with a particle size of 20nm 2 , and drop 0.02g defoamer BYK021 to make PVA / SiO 2 / 50% water dispersion. 2g of hydroxyacrylic resin and 0.5g of partially methylated melamine were dissolved in 2g of butyl acetate, and 0.01g of p-toluenesulfonic acid was added. The solution was rolled onto a standard glass slide with a 30 μm wire bar. After the solvent is fully volatilized and the coating film loses its fluidity, spray a layer of PVA / SiO on it 2 / 17% dispersion. The uncrosslinked double-layer coating is placed in an oven at 90° C. for 0.1-2 hours. After taking it out, cool it to room temperature, put it into 2.5vol% glutaraldehyde aqueous solution (adjust the pH to 2 with hydrochloric acid) and soak for 0.1-3 hours, rinse and dry. Finally, the double-layer coating is heat-treated at 140° C. for 0.1-0.5 hours to fully cross-link the primer. The coa...

Embodiment 3

[0038] Dissolve 5 g of polyvinyl alcohol 1788 with an alcoholysis degree of 88% in 50 g of hot water, and add 3.5 g of ZnO with a particle size of 20 nm to make a PVA / ZnO / 41% dispersion. 2g of hydroxyacrylic resin and 0.2g of fully etherified melamine were dissolved in 5g of butyl acetate, and 0.01g of p-toluenesulfonic acid was added. The solution was rolled onto a standard glass slide with a 120 μm wire bar. After the solvent is fully volatilized and the coating film loses its fluidity, a layer of PVA / ZnO / 41% dispersion is coated on it with a 120 μm wire rod. After the upper liquid film is dried at room temperature, the uncrosslinked double-layer coating is placed in an oven at 70° C. for 0.5-5 hours. After taking it out, cool it to room temperature, put it into 5 vol% formaldehyde aqueous solution (adjust the pH to 2 with sulfuric acid), soak and solidify for 0.1-3 hours, rinse and dry. Finally, the double-layer coating is heat-treated at 120° C. for 0.1-0.5 hours to full...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com