Structure and method for welding target material and backboard

A welding method and backplane technology, applied in welding equipment, non-electric welding equipment, metal material coating process, etc., can solve the problems of low bonding strength, solder melting, large difference in melting point, etc. The effect of metal oxidation and bond strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

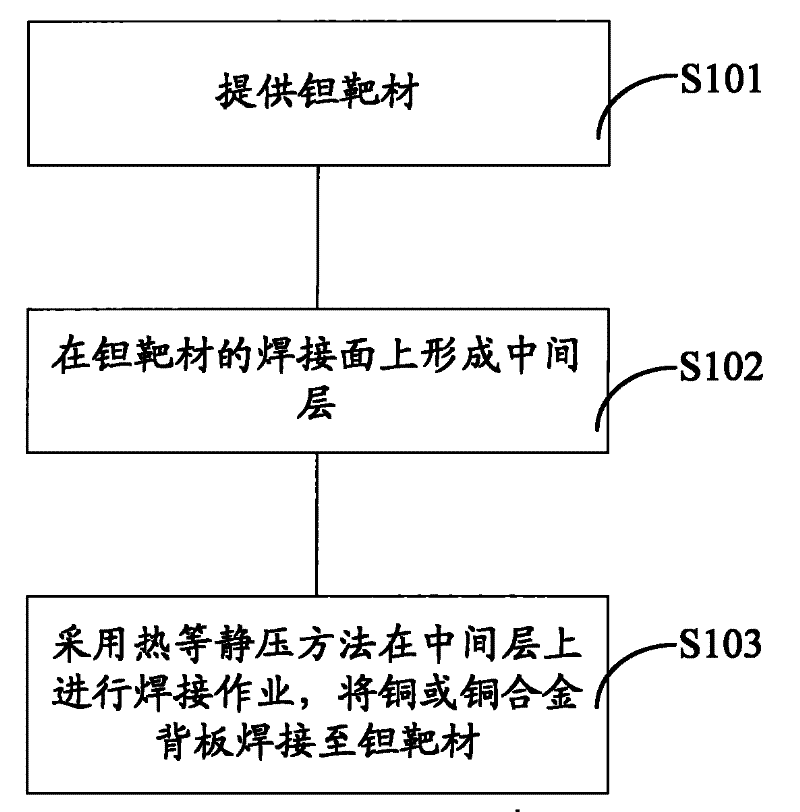

[0020] figure 1 It is a flow chart of a specific embodiment for making the welding structure of the target and the back plate according to the present invention. Such as figure 1 As shown, step S1 is performed to provide a tantalum target;

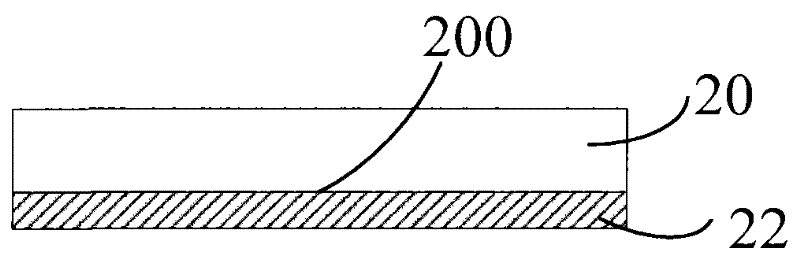

[0021] Execute step S2 to form an intermediate layer on the welding surface of the tantalum target;

[0022] Before forming the intermediate layer, further steps are included: machining the tantalum target material; cleaning the surface of the tantalum target material.

[0023] Wherein, the cleaning of the surface of the tantalum target is specifically pickling with a solvent containing hydrofluoric acid.

[0024] Execute step S3, perform welding operation on the middle layer by hot isostatic pressing method, and weld the copper or copper alloy back plate to the tantalum target.

[0025] The welding structure of the target and the back plate formed based on the above-mentioned embodiment includes: a tantalum target; an intermediate lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com