Patents

Literature

32results about How to "Improve solder joint rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing target material assembly

InactiveCN108149203AIncrease roughnessReduce surface tensionVacuum evaporation coatingSputtering coatingNiobiumEngineering

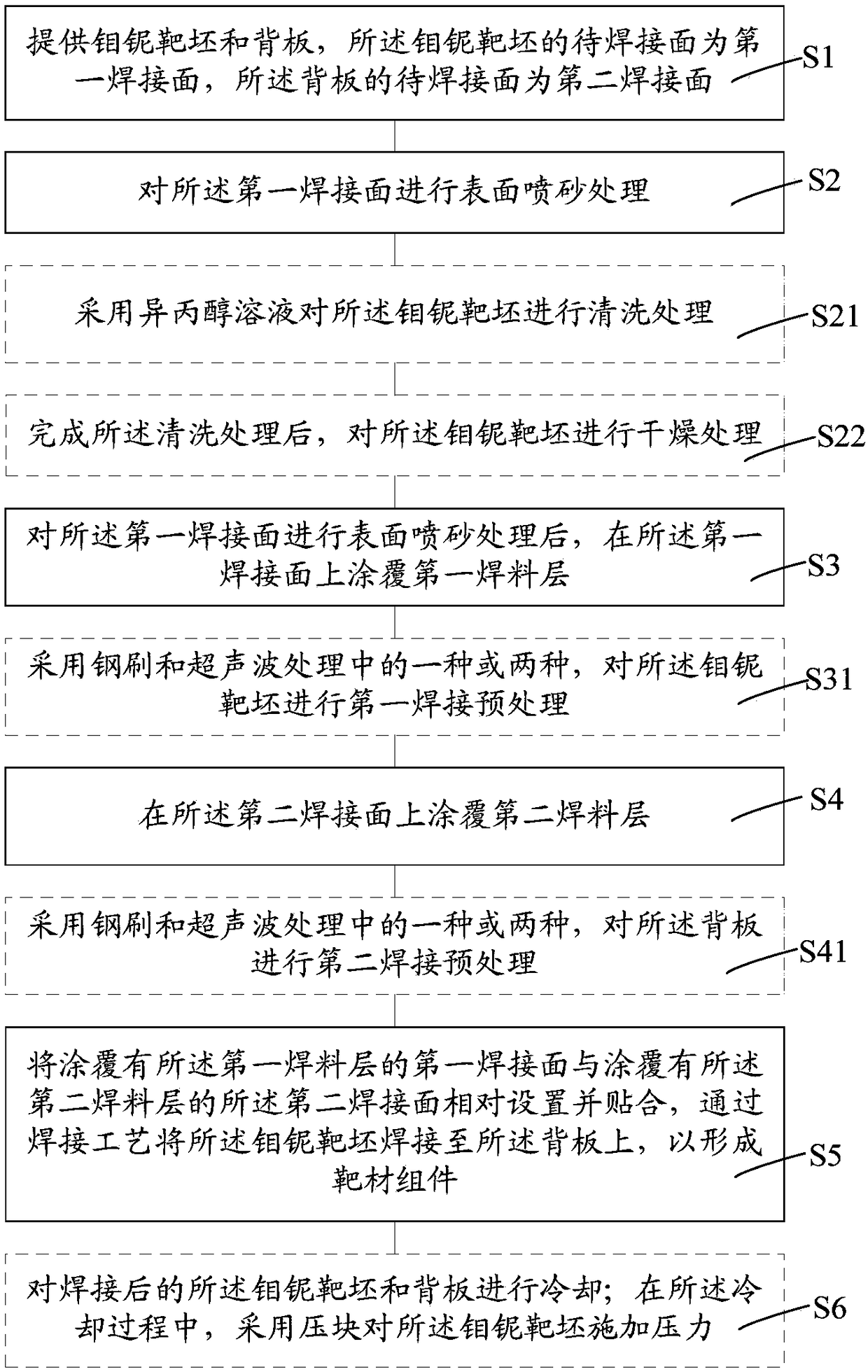

The invention provides a method for manufacturing a target material assembly. The method comprises the steps that a molybdenum-niobium target blank and a back plate are provided, the to-be-welded faceof the molybdenum-niobium target blank is the first welding face, and the to-be-welded face of the back plate is the second welding face; the first welding face is subjected to surface sandblasting treatment; the first welding face after surface sandblasting treatment is coated with a first solder layer; the second welding face is coated with a second solder layer; and the first welding face coated with the first solder layer and the second welding face coated with the second solder layer are oppositely arranged and attached, and the molybdenum-niobium target blank is welded to the back platethrough the welding technology to form the target material assembly. According to the method, after surface sandblasting treatment, the first welding face is coated with the first solder layer, the roughness of the first welding face can be improved through sandblasting treatment, thus the wettability of the first solder layer on the molybdenum-niobium target blank is improved, and then the subsequent welding structure rate of the molybdenum-niobium target blank and the back plate is increased and can reach 95% or above.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

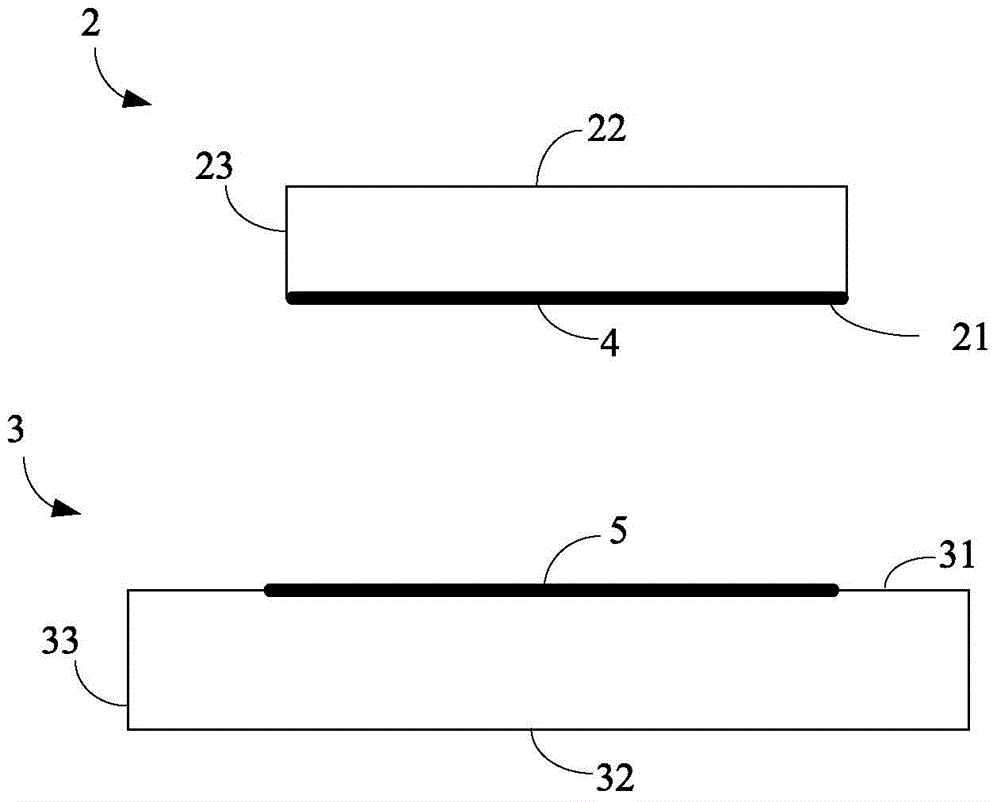

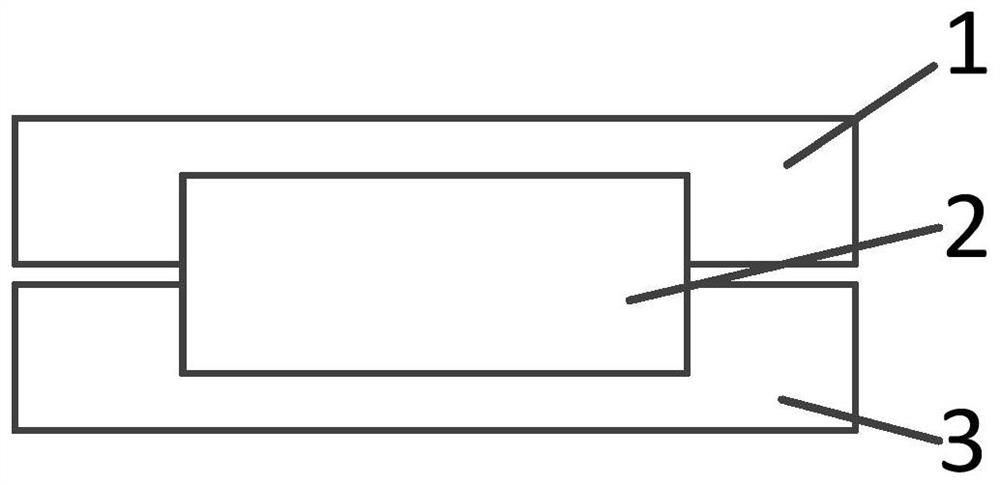

Manufacturing method for target material assembly

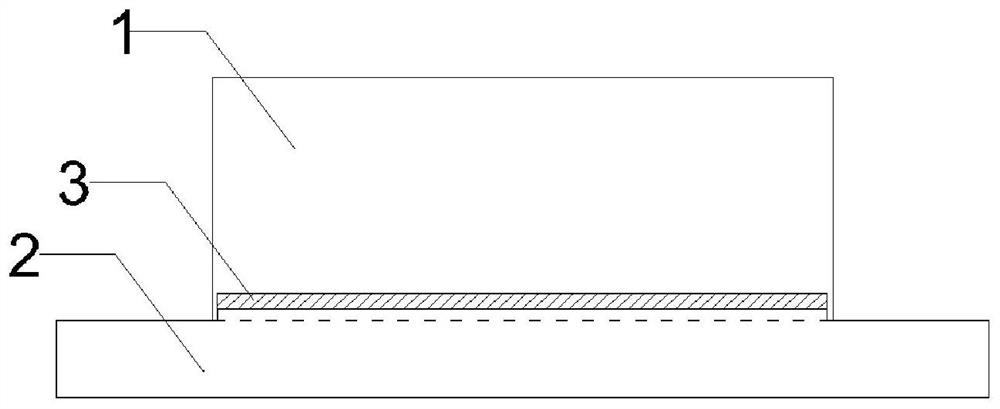

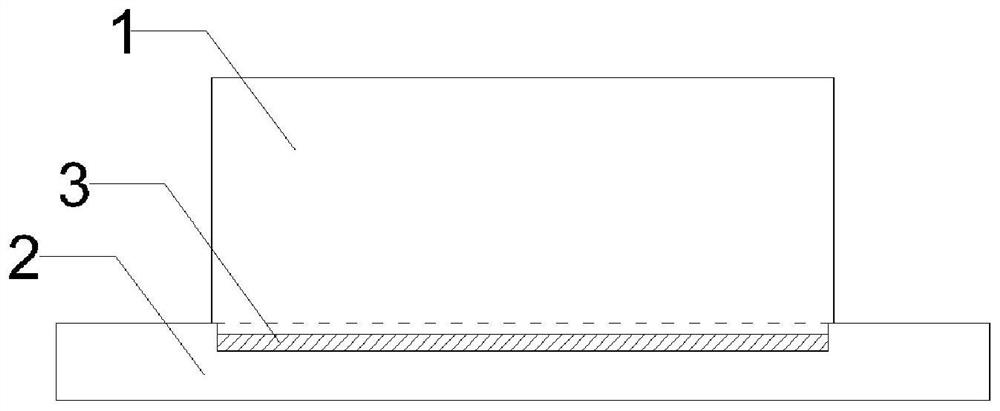

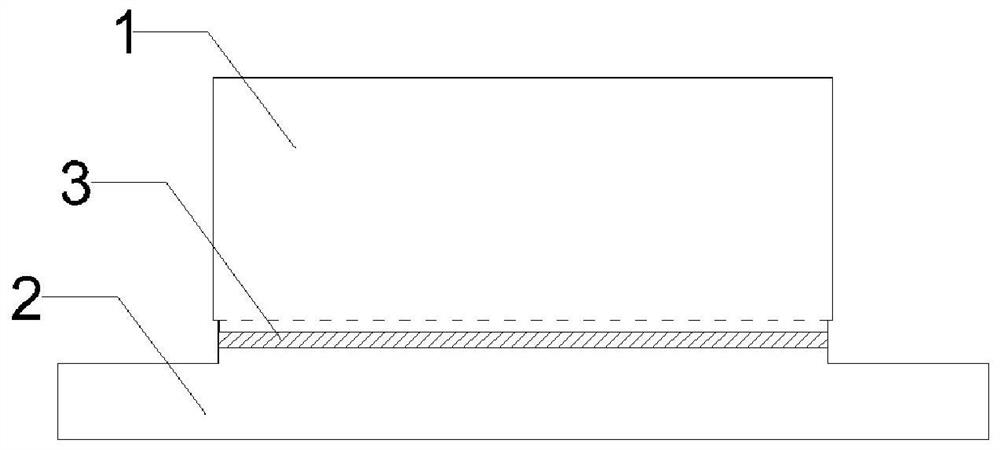

InactiveCN108067723AGood diffusion welding effectImprove solder joint rateWelding/soldering/cutting articlesNon-electric welding apparatusMetallurgySemiconductor

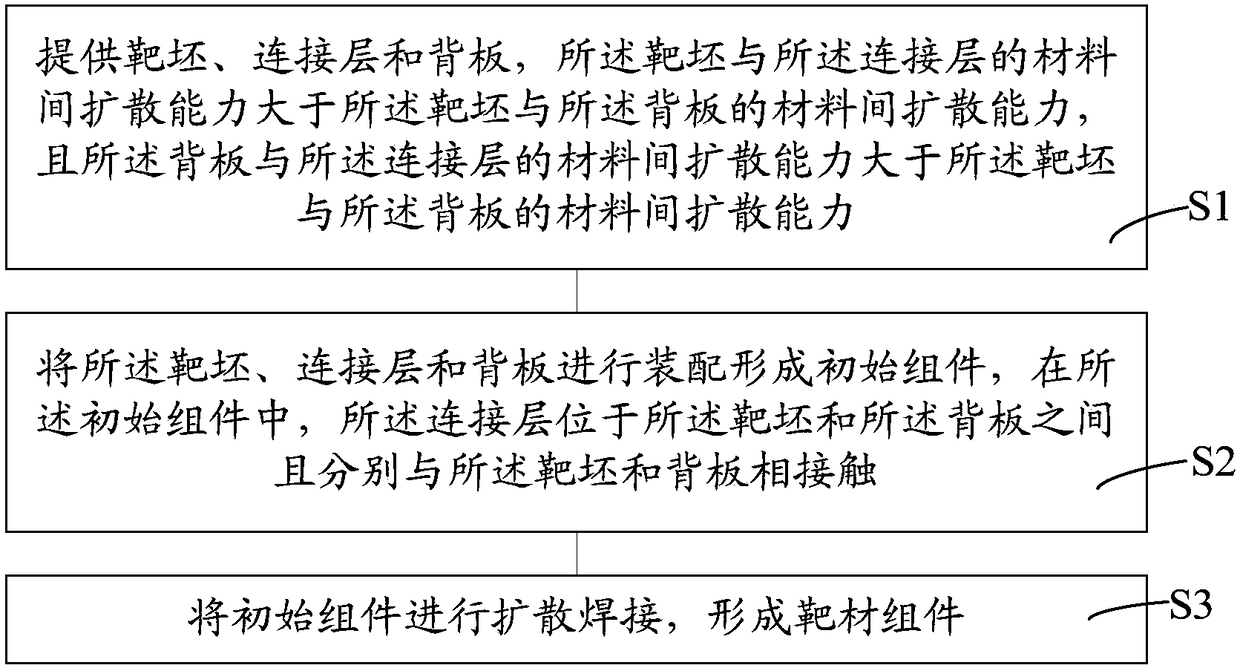

The invention provides a manufacturing method for a target material assembly. The manufacturing method comprises the steps that a target billet, a connecting layer and a backboard are provided, the diffusion ability between materials of the target billet and the connecting layer is larger than the diffusion ability between materials of the target billet and the backboard, and the diffusion abilitybetween materials of the backboard and the connecting layer is larger than the diffusion ability between the materials of the target billet and the backboard; the target billet, the connecting layerand the backboard are assembled to form an initial assembly, and the connecting layer is located between the target billet and the backboard and makes contact with the target billet and the backboard;and the initial assembly is subjected to diffusion welding, and the target material assembly is formed. The connecting layer, the target billet and the backboard all have a good diffusion welding effect, therefore the manufacturing method can increase the welding bonding rate of the target billet and the backboard, the welding bonding rate reaches 99.9% or above accordingly, and the formed targetmaterial assembly meets using requirements of a semiconductor sputtering target material.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

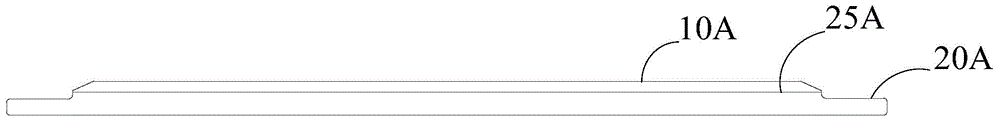

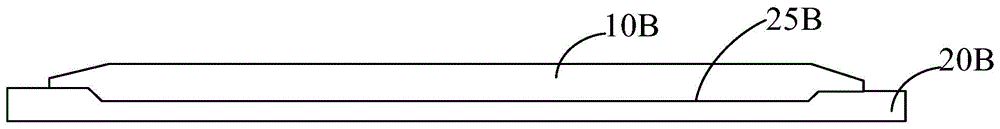

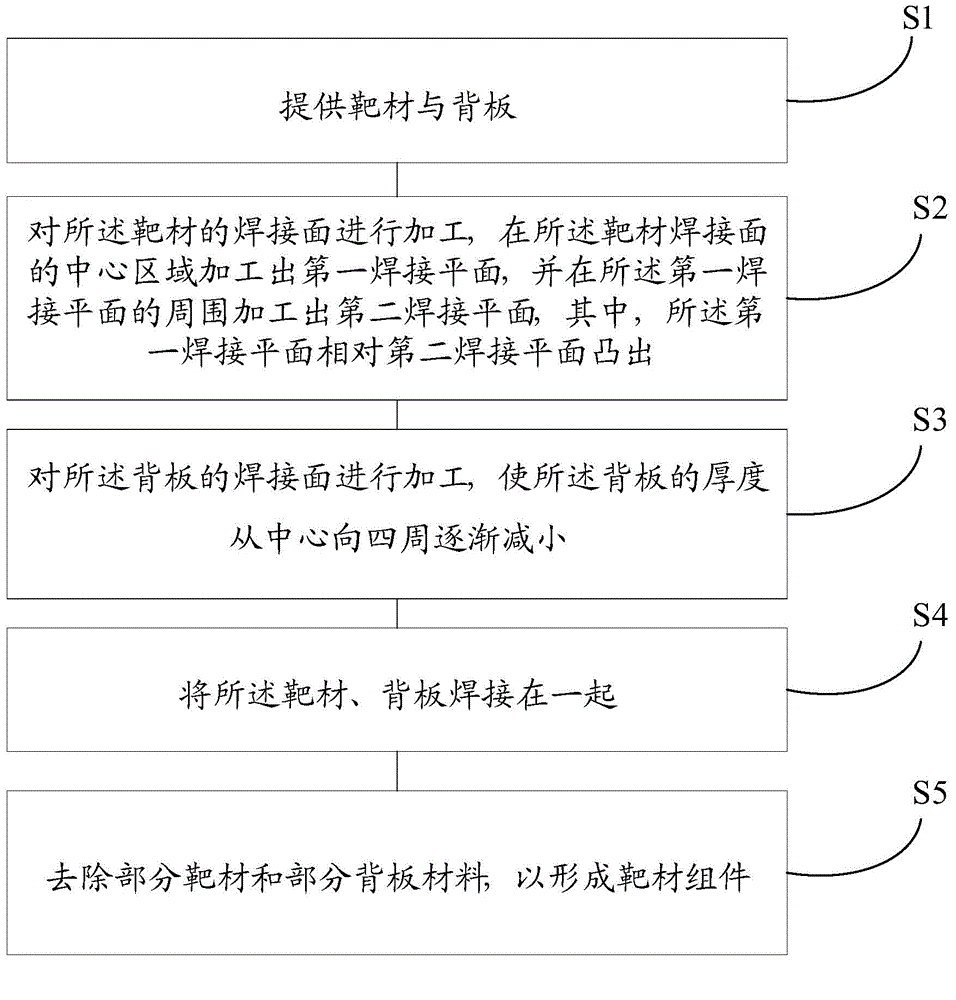

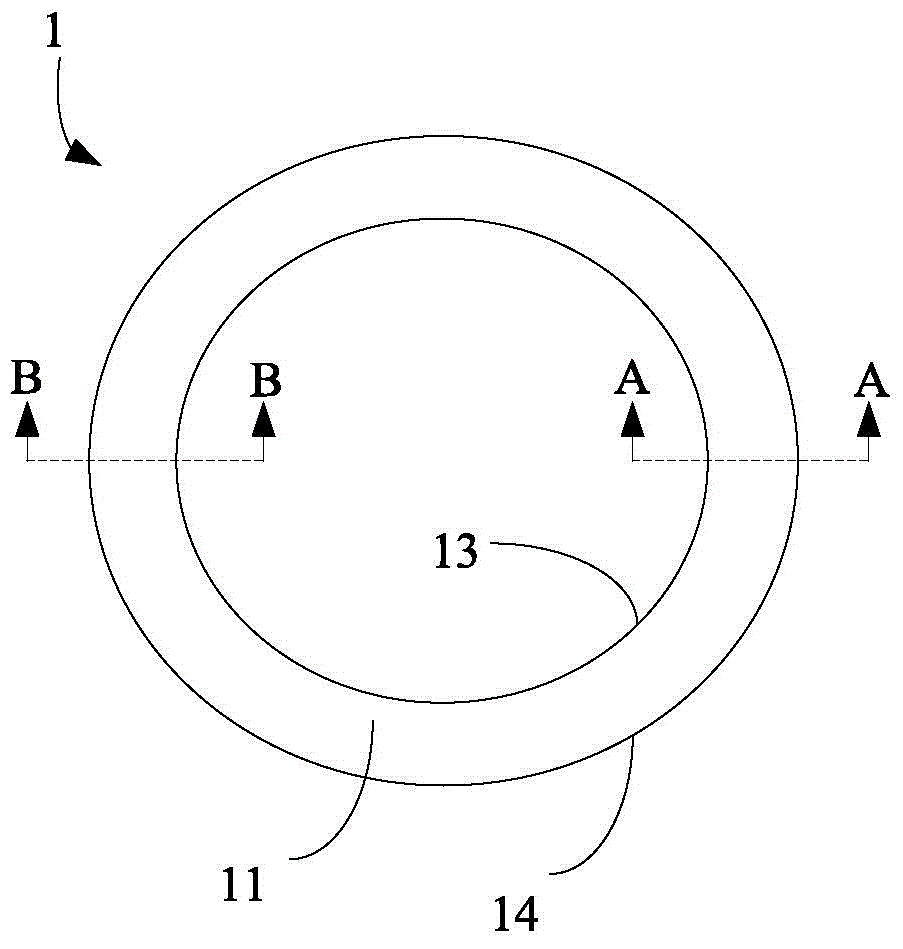

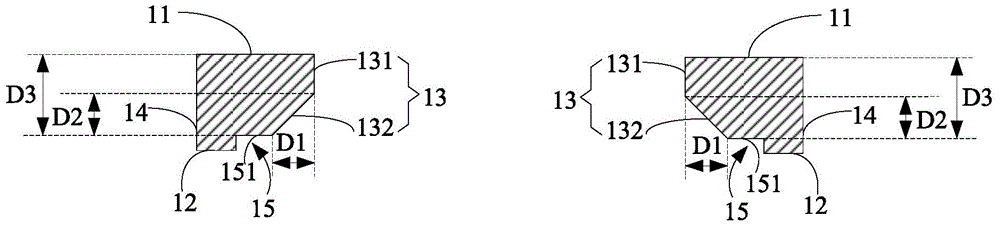

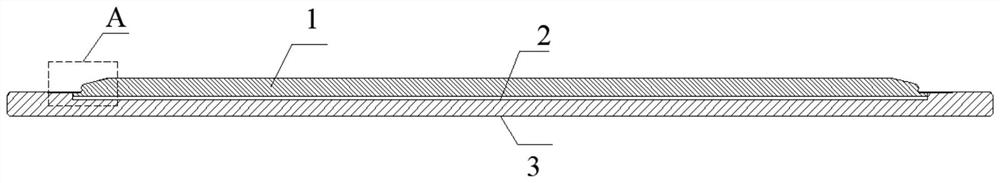

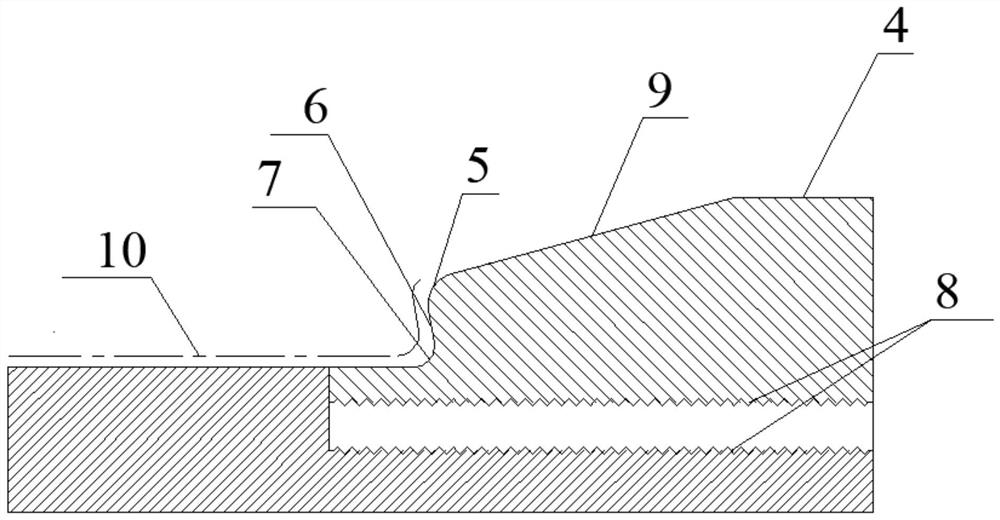

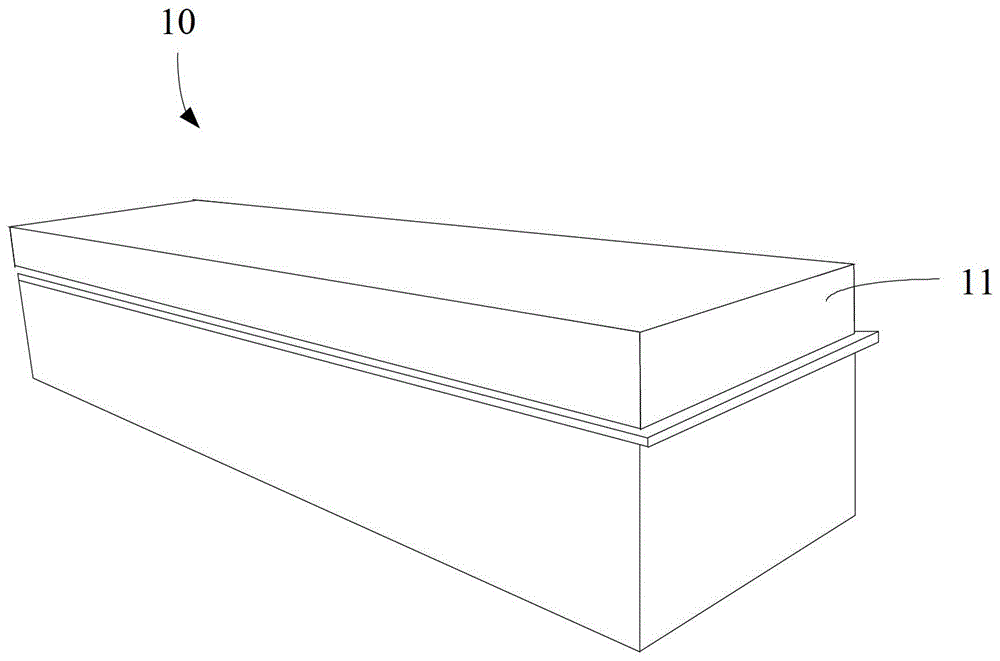

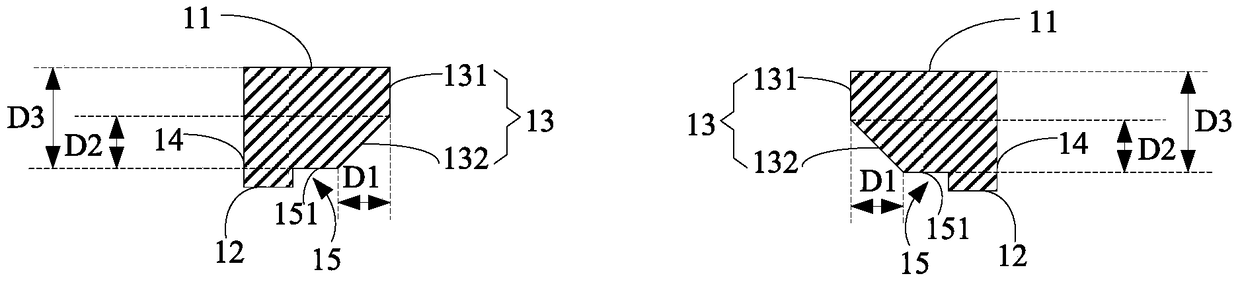

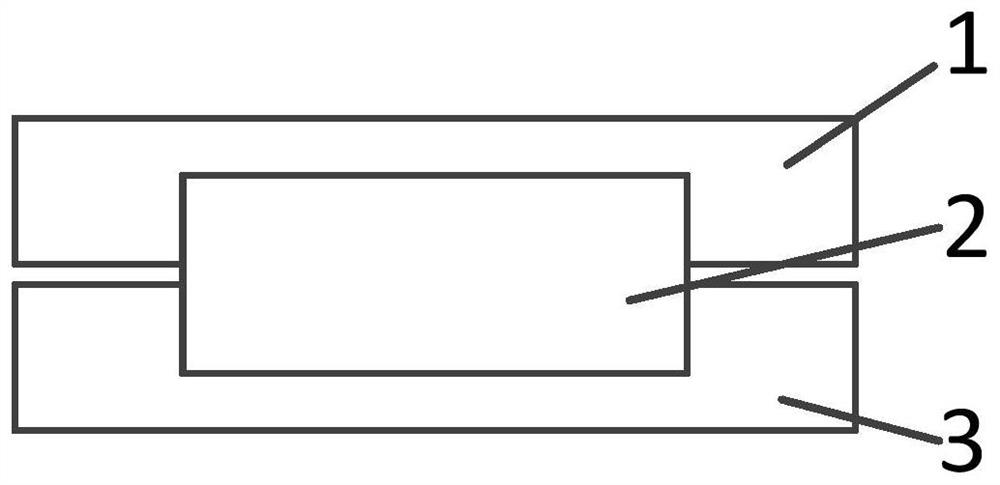

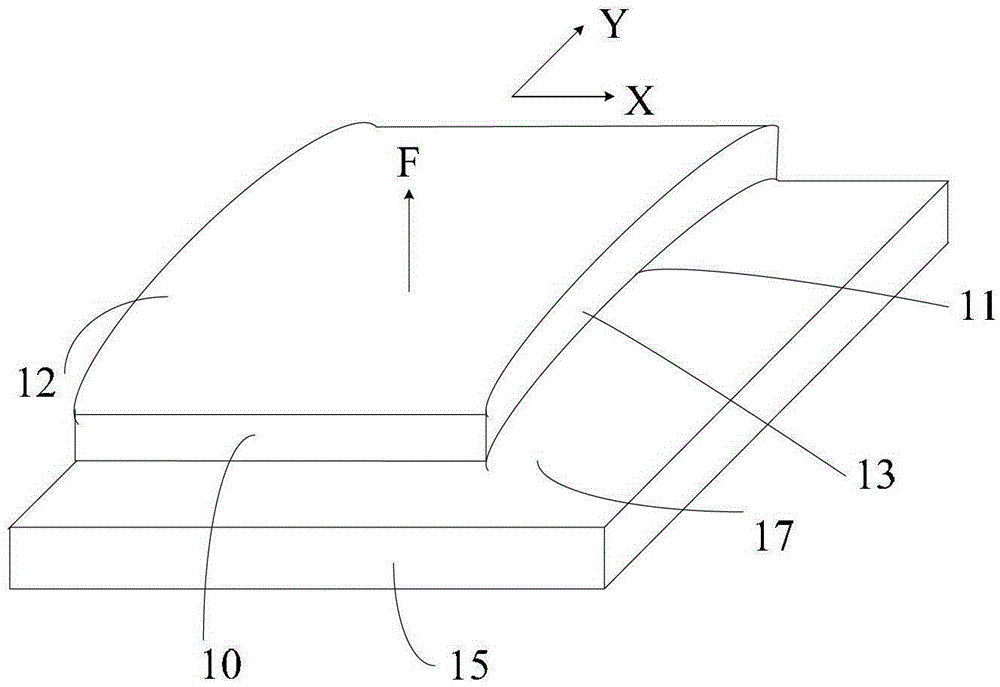

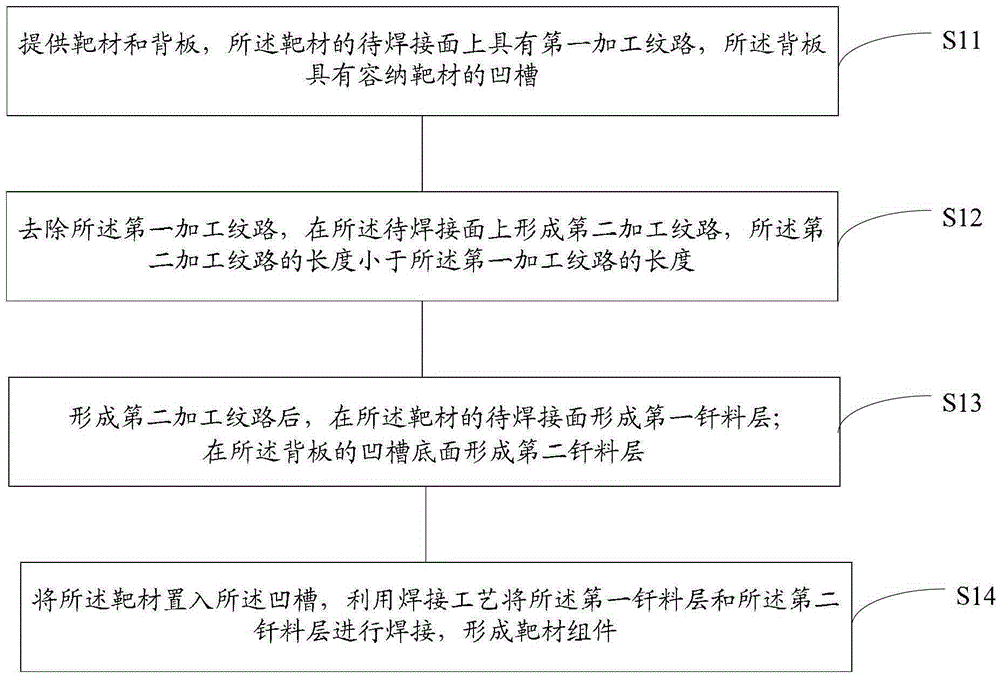

Target assembly and manufacturing method thereof

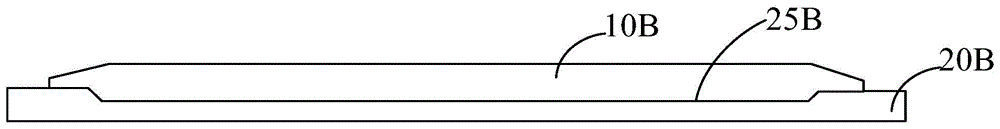

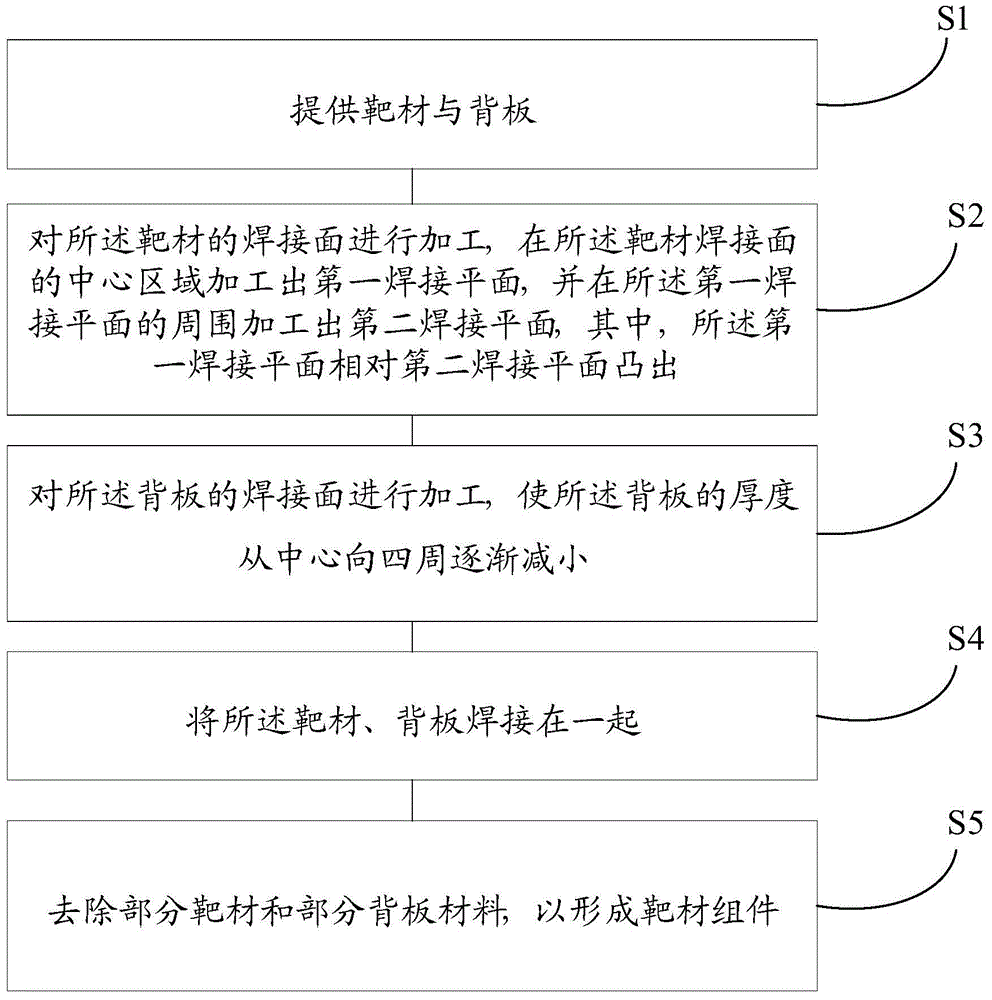

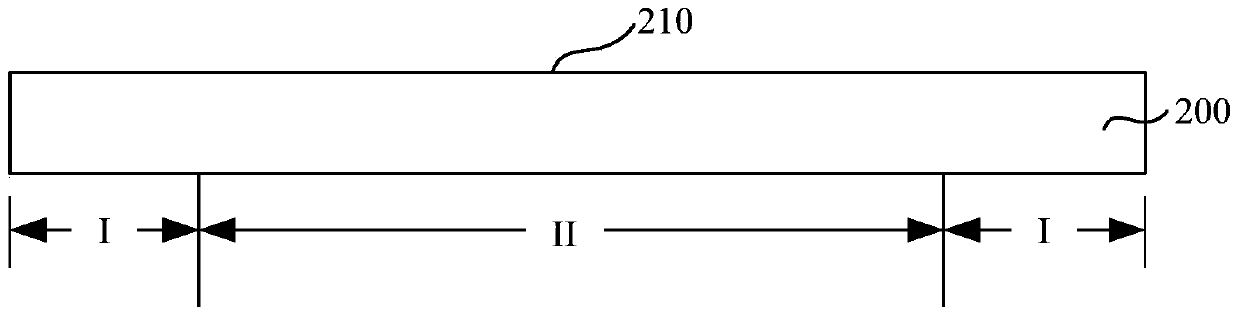

ActiveCN104416281AEasy dischargeAvoid residueVacuum evaporation coatingSputtering coatingMechanical engineeringCentral region

The invention discloses a manufacturing method for a target assembly. The manufacturing method comprises the following steps: providing a target and a back plate; processing a welding surface of the target, processing a first welding plane in a central region of the welding surface of the target, and processing a second welding plane around the first welding plane, wherein the first welding plane is protruded relative to the second welding plane; processing a welding surface of the back plate to enable the thickness of the back plate to be gradually reduced from the center to the surrounding; welding the target and the back plate together; removing part of a material of the target and part of a material of the back plate so as to form the target assembly. The invention also provides a target assembly. The target assembly comprises the target and the back plate; the welding surface of the target is embedded into the welding surface of the back plate. According to the method provided by the invention, retained gas between the target and the back plate is further exhausted, so that the target yield is increased. Furthermore, the invention also provides the target assembly obtained by the method.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

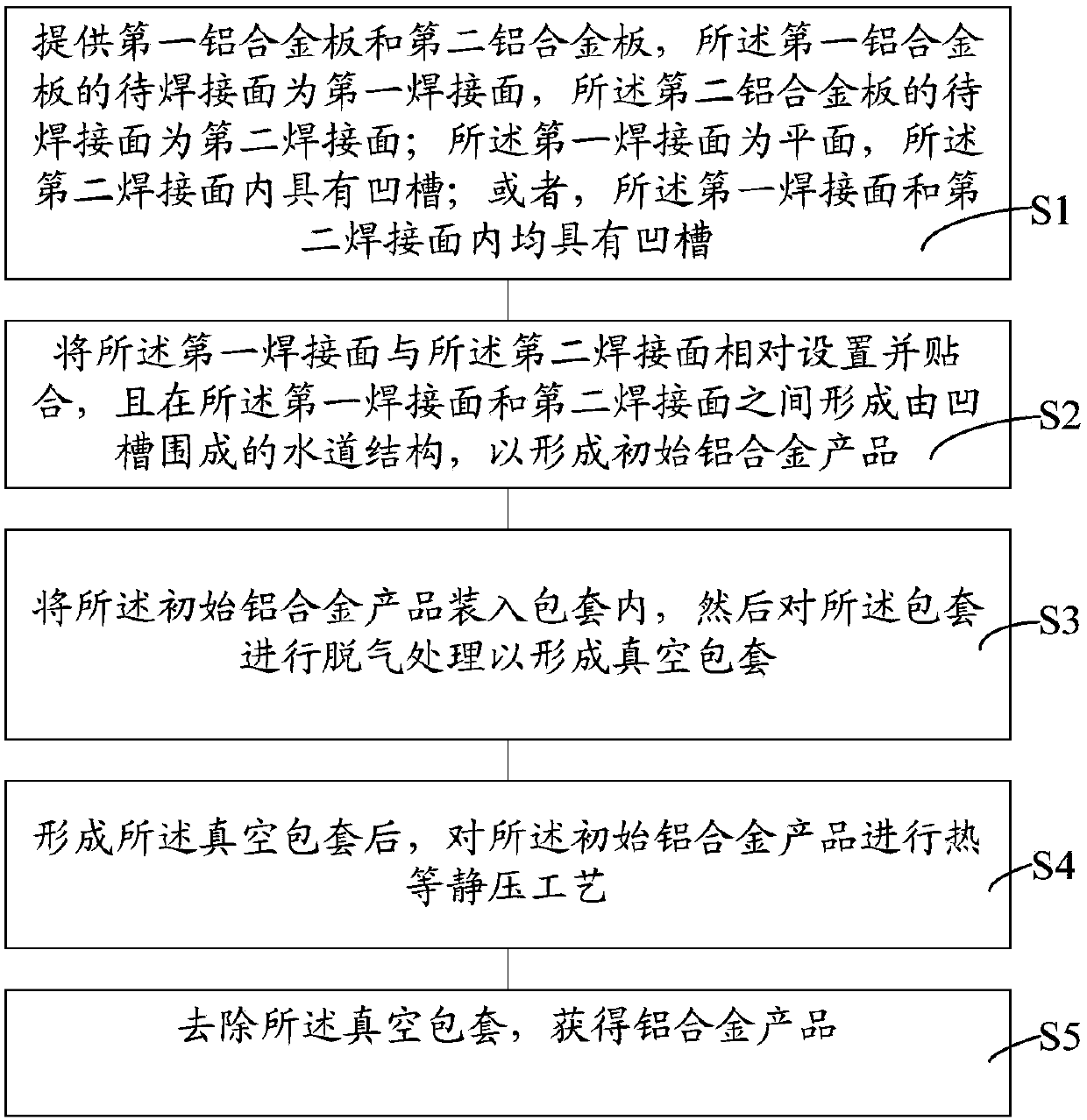

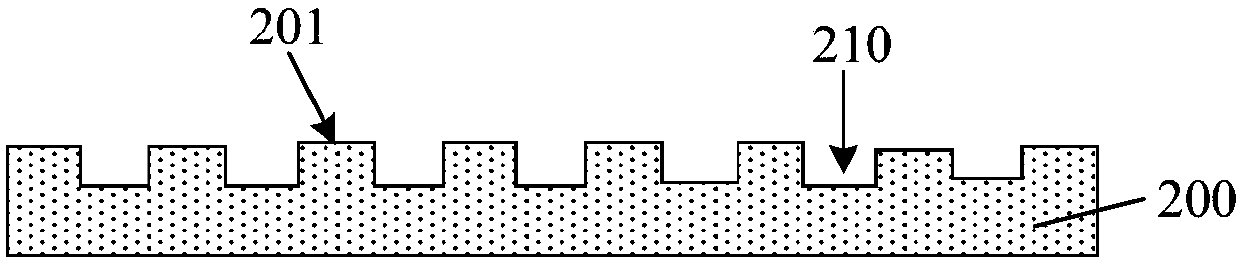

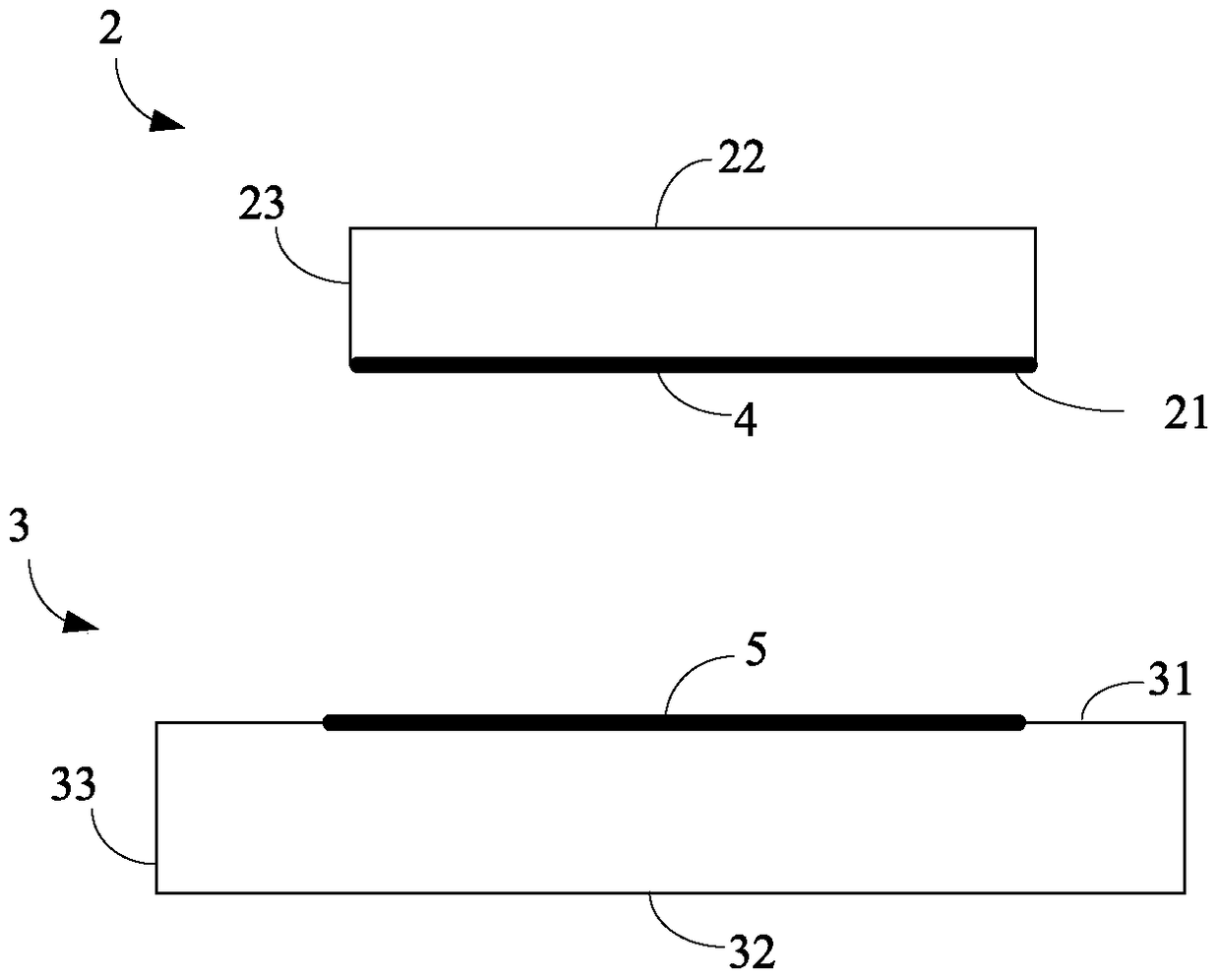

Manufacturing method of aluminum alloy product

InactiveCN107662045AImprove welding strengthAvoid deformation or even blockageNon-electric welding apparatusHot isostatic pressingWeld strength

The invention provides a manufacturing method of an aluminum alloy product. The manufacturing method of the aluminum alloy product comprises the following steps: a first aluminum alloy plate and a second aluminum alloy plate are provided, wherein a surface to be welded of the first aluminum alloy plate is a first welded surface, and a surface to be welded of the second aluminum alloy plate is a second welded surface; the first welded surface is a plane, and a groove is formed in the second welded surface; or grooves are formed in the first welded surface and the second welded surface; the first welded surface and the second welded surface are oppositely arranged and bonded, and a water way structure, surrounded by the grooves, is formed between the first welded surface and the second welded surface to form an initial aluminum alloy product; the initial aluminum alloy product is filled in a cover; the cover is degassed to form a vacuum cover; then, a hot isostatic pressing process is performed on the initial aluminum alloy product; and the vacuum cover is removed to obtain the aluminum alloy product. As the hot isostatic pressing process is applied on the initial aluminum alloy product, the welding strength of the formed aluminum alloy product is improved, and meanwhile, deformation or even blockage of the water way structure is prevented.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

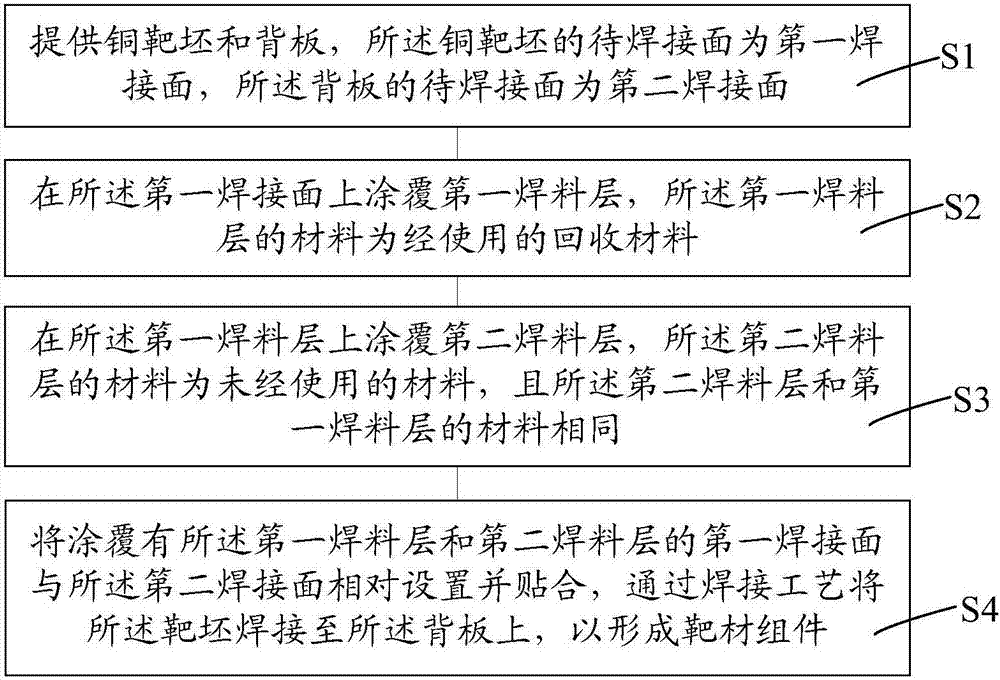

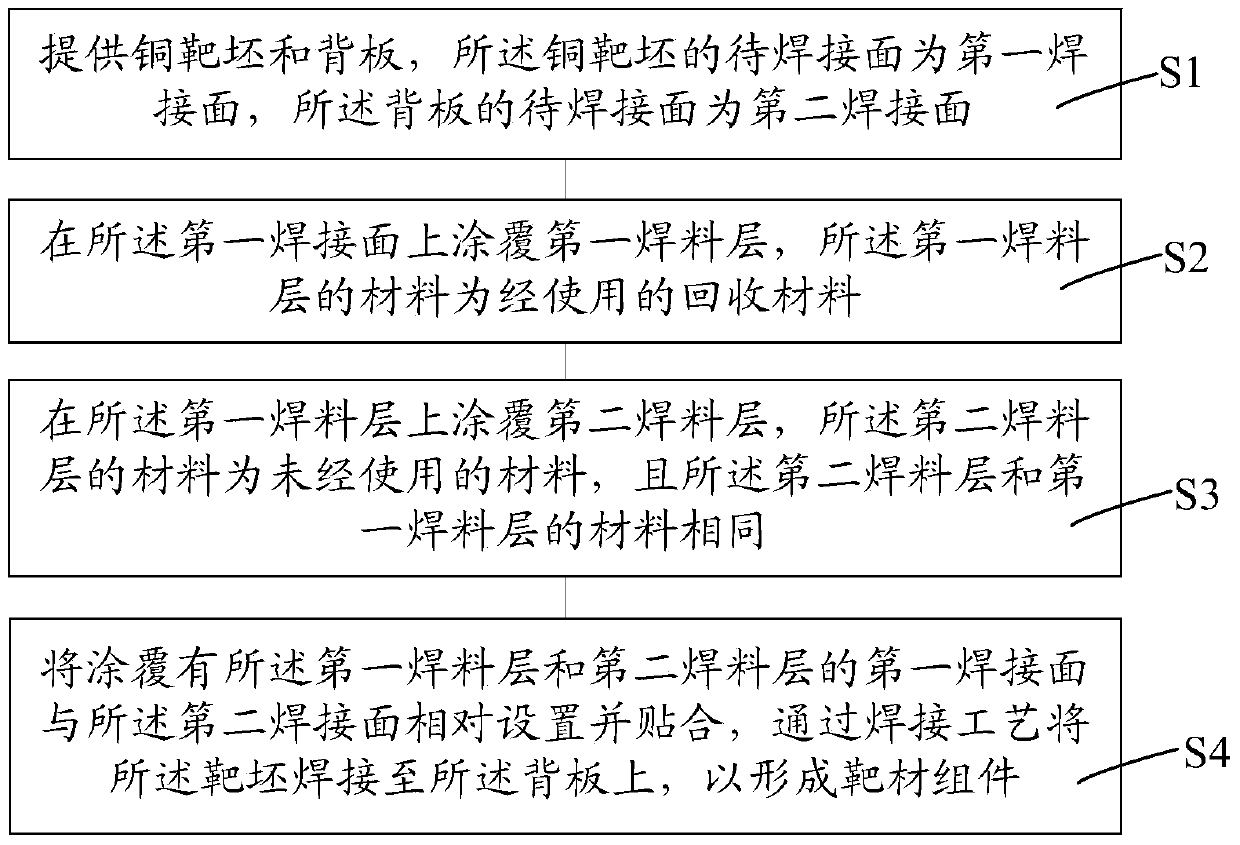

Manufacture method of target material assembly

ActiveCN107570905AImprove solder joint rateImprove wettabilityVacuum evaporation coatingSputtering coatingCopperBackplane

The invention provides a manufacture method of a target material assembly. The method comprises the following steps: providing a copper target blank and a back board, wherein a to-be-welded surface ofthe copper target blank is a first welding surface and a to-be-welded surface of the back board is a second welding surface; coating the first welding surface with a first solder layer, the materialof which is used recovery material; coating the first solder layer with a second solder layer, the material of which is not used, wherein the second solder layer and the first solder layer are the same in material; enabling the first welding surface coated with the first solder layer and the second welding surface coated with the second solder layer to be oppositely arranged and attached with eachother, welding the target blank to the back board by welding technology in order to form the target material assembly. The material of the first solder layer is used recovery material while the material of the second solder layer is not used. Compared with a scheme adopting only one solder layer, welding bonding efficiency of the target blank and the back board can be increased after mutual fusion between the first solder layer and the second solder layer.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

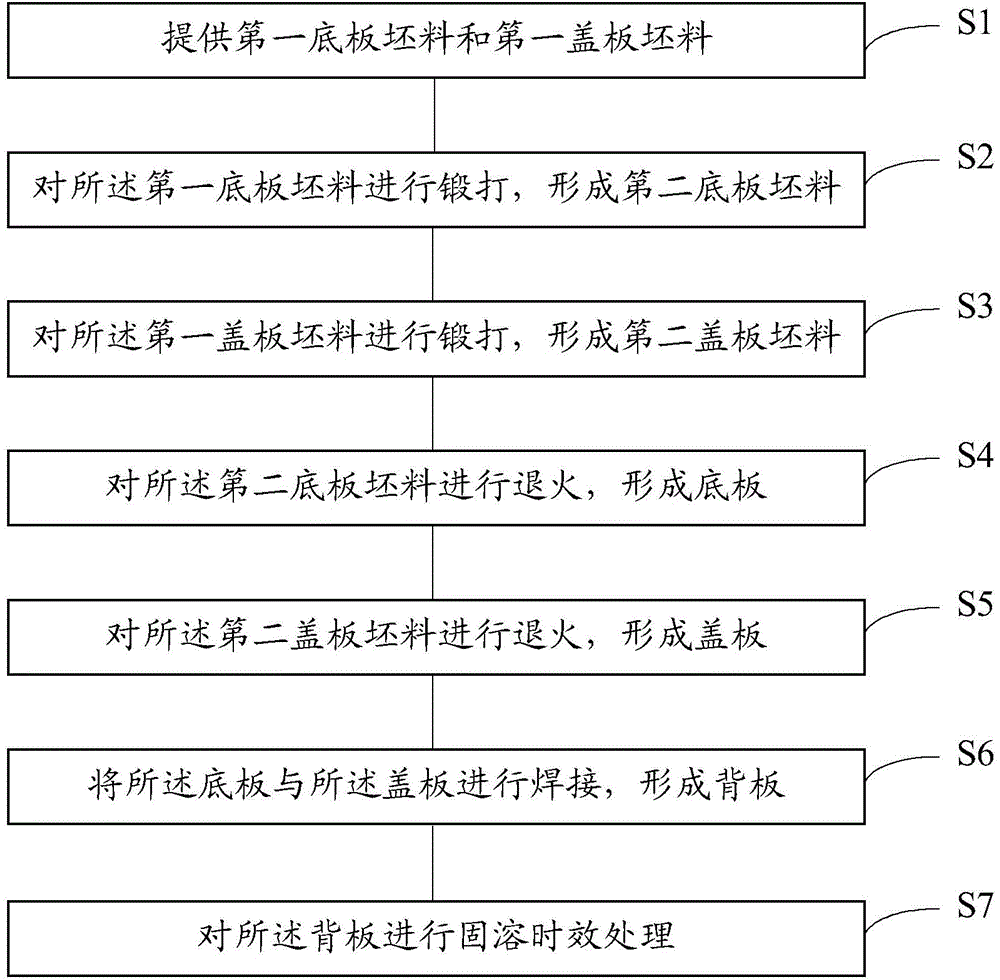

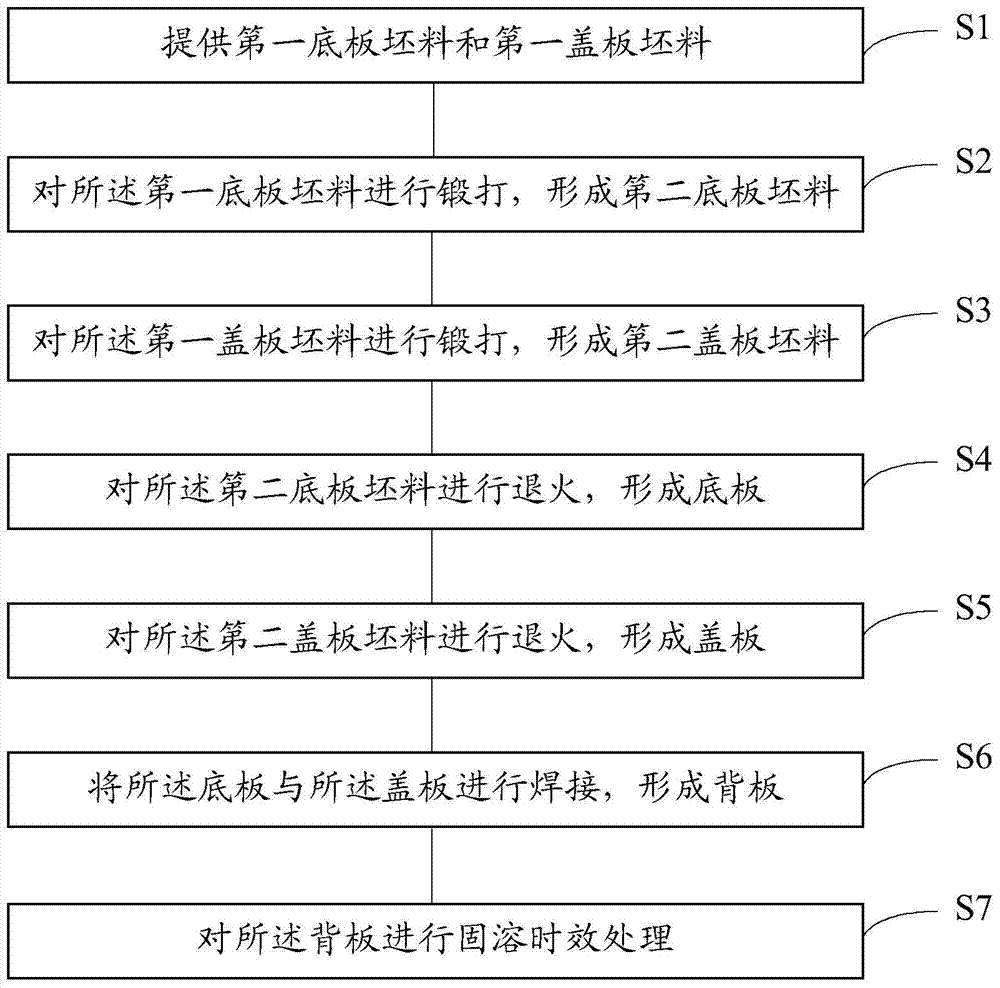

Method for forming back plate

ActiveCN104668897AConducive to the formation of segregationHigh hardnessVacuum evaporation coatingSputtering coatingEngineering

Disclosed is a method for forming a back plate. The method includes that a first bottom plate blank and a first cover plate blank are provided; the first bottom plate blank is subjected to forging to form a second bottom plate blank; the first cover plate blank is subjected to forging to form a second cover plate blank; the second bottom plate blank is subjected to annealing to form a bottom plate; the second cover plate blank is subjected to annealing to form a cover plate; the bottom plate and the cover plate are welded to form the back plate. By means of the method for forming the back plate, the back plate can be applied to a magnetron sputtering process, qualities of films formed on a substrate can be improved, and costs of the magnetron sputtering process are lowered.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Welding jig and manufacturing method for target assembly

ActiveCN105436649AHigh concentricityEasy alignmentWelding/cutting auxillary devicesAuxillary welding devicesWelding processBackplane

The invention discloses a welding jig and a manufacturing method for a target assembly. The manufacturing method for the target assembly includes the steps that a target, a back plate and the welding jig are provided; a first solder layer is formed on a face to be welded of the target through solder; a second solder layer is formed on a face to be welded of the back plate through solder; the target with the first solder layer and the back plate with the second solder layer are fixed to the welding jig; and the first solder layer and the second solder layer are combined through a welding process, so that the target assembly is formed. According to the target assembly formed by the manufacturing method for the target assembly, the requirements for stably producing and using the ceramic target for a long time can be met, and the service life of the target assembly can be greatly prolonged.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Brazing welding method for circular target material and back plate

PendingCN112958864AImprove solder joint rateReduce defective rateWelding/cutting media/materialsSoldering mediaCopper wireWelding

The invention relates to a brazing welding method for a circular target material and a back plate. The method comprises the following steps that the target material and the back plate with a groove are prepared firstly, the bottom surface of the groove is a back plate welding surface, welding flux is placed on a target material welding surface and the back plate welding surface respectively, the temperature is raised, and the molten welding flux is used for infiltration treatment; then, the welding flux is placed in the groove of the back plate subjected to infiltration treatment, copper wires with the diameter being 0.5-0.6 mm are arranged at equal intervals, and the treated back plate is obtained; and the treated target material and the treated back plate are buckled and assembled, a pressing block is placed on a sputtering face of the target material, cooling is conducted, and a circular target material assembly is obtained. According to the method, the diameter of the copper wires serving as supporting strips is limited to be 0.5-0.6 mm, compared with the diameter of copper wires in the prior art, the diameter of the copper wires is increased, a welding flux layer can be thickened, the welding binding rate is increased to be larger than or equal to 97%, and the single defect rate is reduced to be smaller than or equal to 1.5%.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Welding method of titanium target and copper back plate

InactiveCN112059349AImprove solder joint rateExtended service lifeSoldering apparatusMetal working apparatusSand blastingTitanium

The invention relates to a welding method for a titanium target and a copper back plate. The welding method comprises the following steps that (1), sand blasting and acid treatment are sequentially conducted on the welding face of the titanium target and the welding face of the copper back plate; and (2), welding flux is added to the welding faces of the titanium target and the copper back plate after acid treatment, and then brazing is conducted to obtain a titanium target assembly. According to the welding method, due to the fact that special treatment, namely sand blasting and acid treatment are sequentially adopted on the welding faces, the coupling effect between the sand blasting and the acid treatment is utilized, the welding bonding rate is remarkably increased, the welded productdoes not deform, and meanwhile the back plate can also be repeatedly used.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Target material assembly as well as preparation method and application thereof

ActiveCN113458728AAlleviate the problem of difficult diffusionImprove bindingVacuum evaporation coatingSputtering coatingSand blastingMaterial Crack

The invention provides a target material assembly as well as a preparation method and application thereof. The target material assembly comprises a target material main body, a middle layer and a target material back plate connected with the target material main body through the middle layer, wherein the target material main body comprises a sputtering surface, a main body side surface connected with the sputtering surface through a first chamfer, a main body sand blasting surface connected with the main body side surface through a second chamfer, and a welding surface opposite to the sputtering surface; a thread is arranged on the welding surface; one surface, connected with the middle layer, of the target material back plate is a front surface; a groove concentric with the target material back plate is formed in the front surface of the target material back plate; a thread is arranged at the bottom of the groove; and the middle layer is arranged in the groove. According to the target material assembly, the overall structure is optimized, the welding combination law and the welding combination strength between the target material body and the target material back plate are improved, the situation that the titanium-aluminum alloy target material cracks in the welding process is reduced, and industrial production is facilitated.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

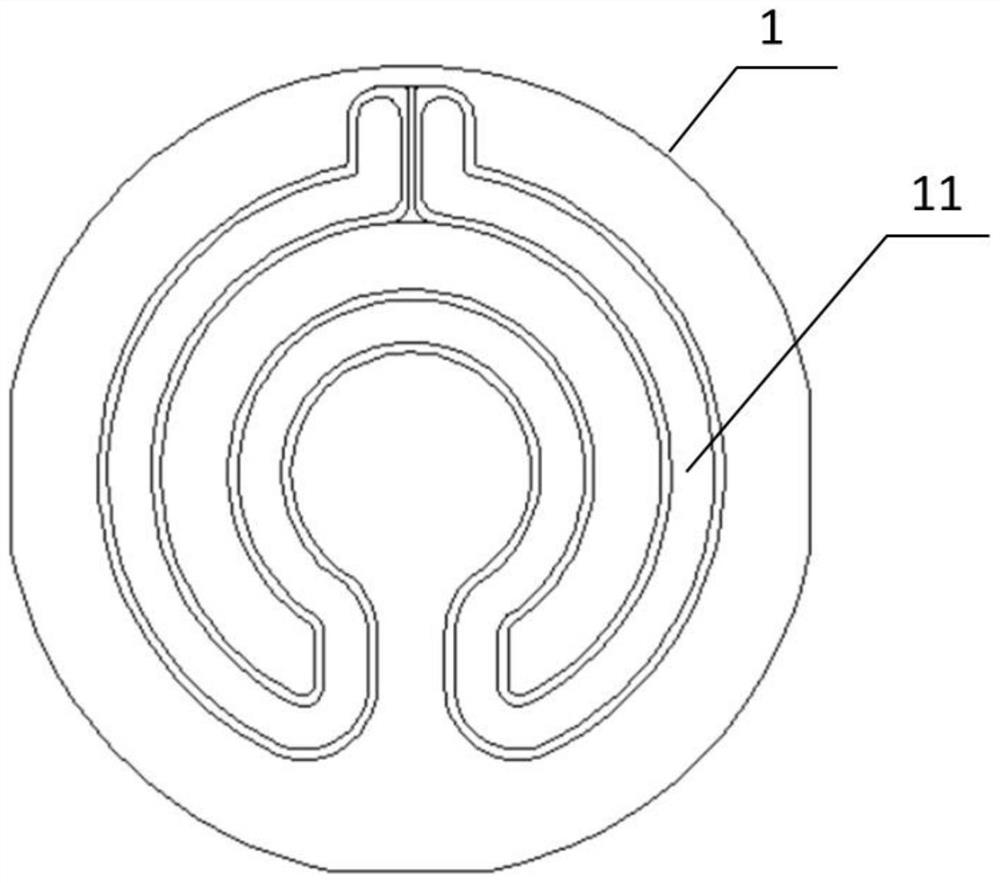

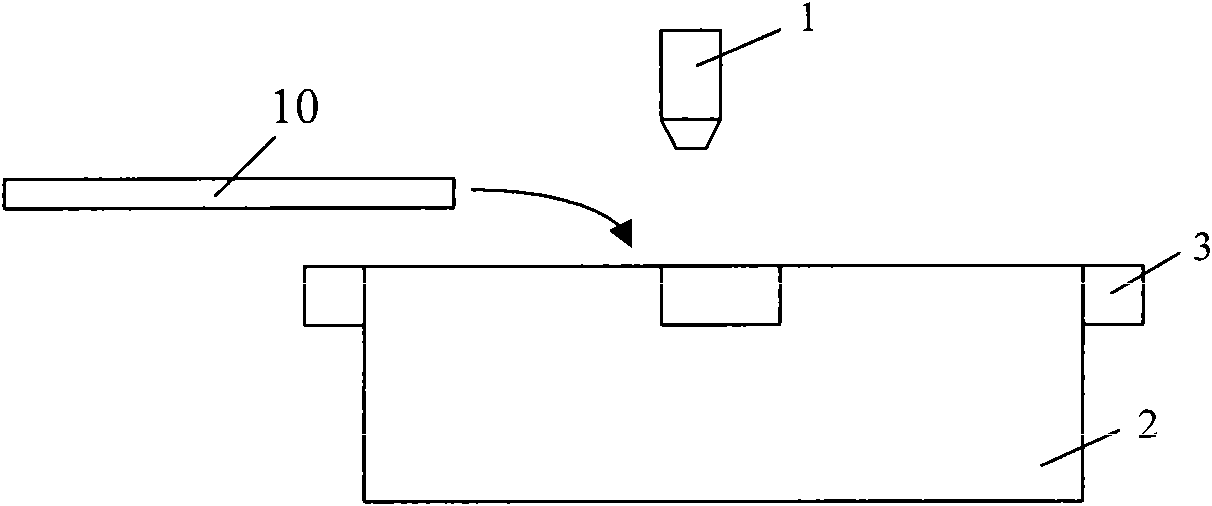

Heating plate of welding platform, manufacturing method of welding platform, and welding platform

ActiveCN104416307BEliminate crush marksHigh hardnessVacuum evaporation coatingWelding/cutting auxillary devicesSputteringEngineering

Disclosed are a heating plate for a welding bench, a manufacturing method of the welding bench and the welding bench. The welding bench is used for welding a target and a back plate and comprises a base having a supporting face and at least two heating plates arranged on the supporting face; every two adjacent heating plates has spacing. The welding bench allows an operator to extend a forklift arm into the spacing and hold a large sputtering target component from beneath the spacing, the large sputtering target component is removed from the welding bench, and no damage is caused to the large sputtering target component.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

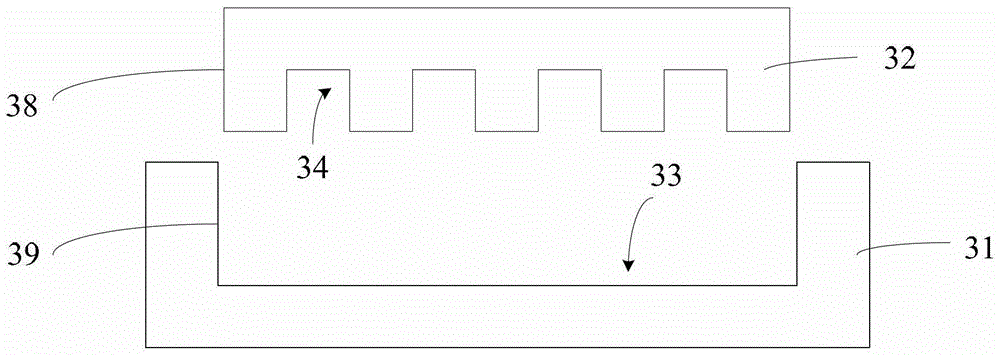

Forming method of backplane and backplane

ActiveCN104588807BNo cloggingWill not deformVacuum evaporation coatingSoldering apparatusEngineeringFiller metal

Provided are a method for forming a backboard and the backboard. The method for forming the backboard comprises the steps that a bottom plate and a cover plate are provided, the surface, facing one side of the cover plate, of the bottom plate is the top face of the bottom plate, the top face of the bottom plate is a plane, the bottom face of the cover plate is a plane, and cooing water channel slot structures are arranged on the bottom of the cover plate; the cooling water channel slot structures and the bottom plate form cooling water channels; the bottom face of the cover plate and the top face of the bottom plate are welded through the brazing technique to form the backboard. By the adoption of the method, the assembly difficulty coefficient of the cover plate, brazing filler metal and the bottom plate can be reduced, and the formed backboard is high in soldering binding rate. In addition, the cover plate is not prone to deformation.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Welding method for WTi target and copper back plate

ActiveCN111843161AImprove welding effectImprove solder joint rateWelding/soldering/cutting articlesNon-electric welding apparatusCopperInternal stress

The invention relates to a welding method for a WTi target and a copper back plate. The welding method comprises the following steps: assembling the WTi target, the copper back plate and a cover plate; then putting an assembled body into a sheath for degassing and welding in sequence, wherein the welding face of the WTi target is provided with a groove; and carrying out acid treatment and alkali treatment on the welding face of the copper back plate in sequence. The assembly means symmetric assembly of the copper back plate and the cover plate with the WTi target as the center. According to the welding method provided by the invention, by arranging the groove on the welding face of the target, carrying out acid treatment and alkali treatment on the welding face of the back plate and usinga specific assembling mode, effective welding of the WTi target and the copper back plate is realized, and internal stress is reduced at the same time; in addition, no cracks after discharging are produced; and meanwhile, the phenomena of point discharge, arc discharge and the like in the use process are also effectively avoided.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Preparation method of semiconductor high-purity titanium target material assembly

The invention provides a preparation method of a semiconductor high-purity titanium target material assembly. The preparation method comprises the following steps: independently and sequentially subjecting a cover plate and a substrate provided with a cooling water channel to forging stretching, primary heat treatment, calendering and secondary heat treatment; assembling the treated cover plate and the substrate, and performing friction stir welding to obtain a back plate; and assembling the obtained back plate and a titanium target material, fixing the titanium target material through a clamp, and then performing brazing to obtain a high-purity titanium target material assembly. According to the preparation method, by optimizing the heat treatment process and the welding mode in the preparation process, the welding binding rate of the target material assembly is effectively increased, the optimized back plate can be repeatedly used, and cost reduction is facilitated.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method for improving welding bonding rate of tungsten-containing target material

PendingCN113290293AImprove compactnessSubsequent infiltrationSoldering apparatusVacuum evaporation coatingFiller metalFilm-coated tablet

The invention provides a method for improving the welding bonding rate of a tungsten-containing target material. The method comprises the following steps: cleaning the welding face of the tungsten-containing target material, and then carrying out film coating on the sputtering face of the target material through a physical vapor deposition method so as to obtain a film-coated target material; and soaking the welding faces of the film-coated target material and a back plate with brazing filler metal and then welding the welding faces of the film-coated target material and the back plate to obtain a target material assembly. According to the method, aiming at the defects existing in target material film coating of a traditional film coating method, the physical vapor deposition method is adopted, an appropriate film coating process is selected according to the characteristics of the specific target material, the requirements of subsequent soaking and welding are met, the obtained film coating layer is high in compactness, thus the welding bonding rate can be increased, and the qualified target material assembly is obtained; and the method is easy to operate, the film coating quality is high, reworking can be reduced, the cost is reduced, and the application prospect is wide.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

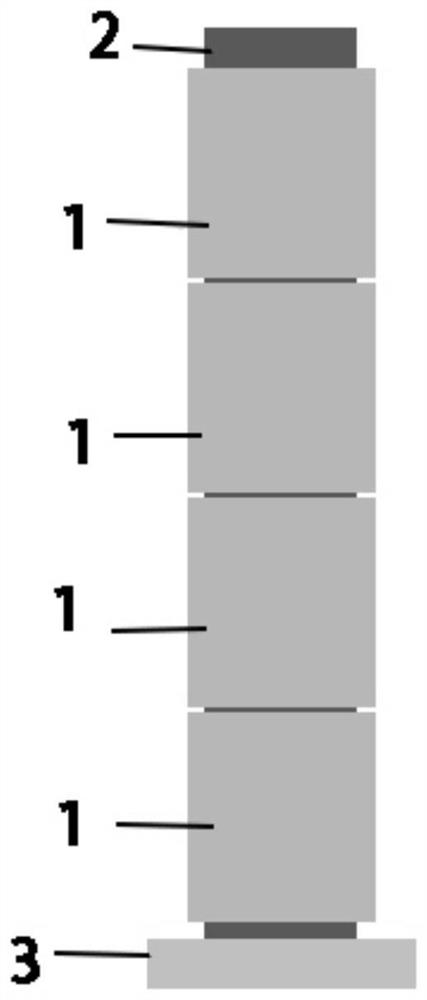

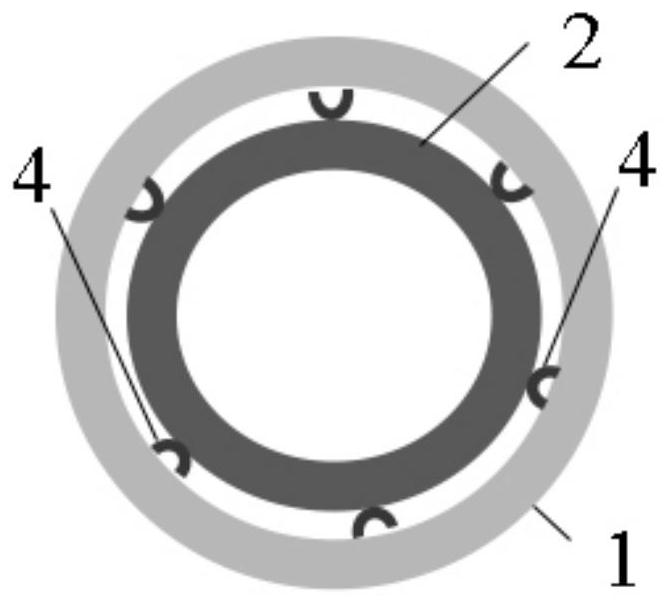

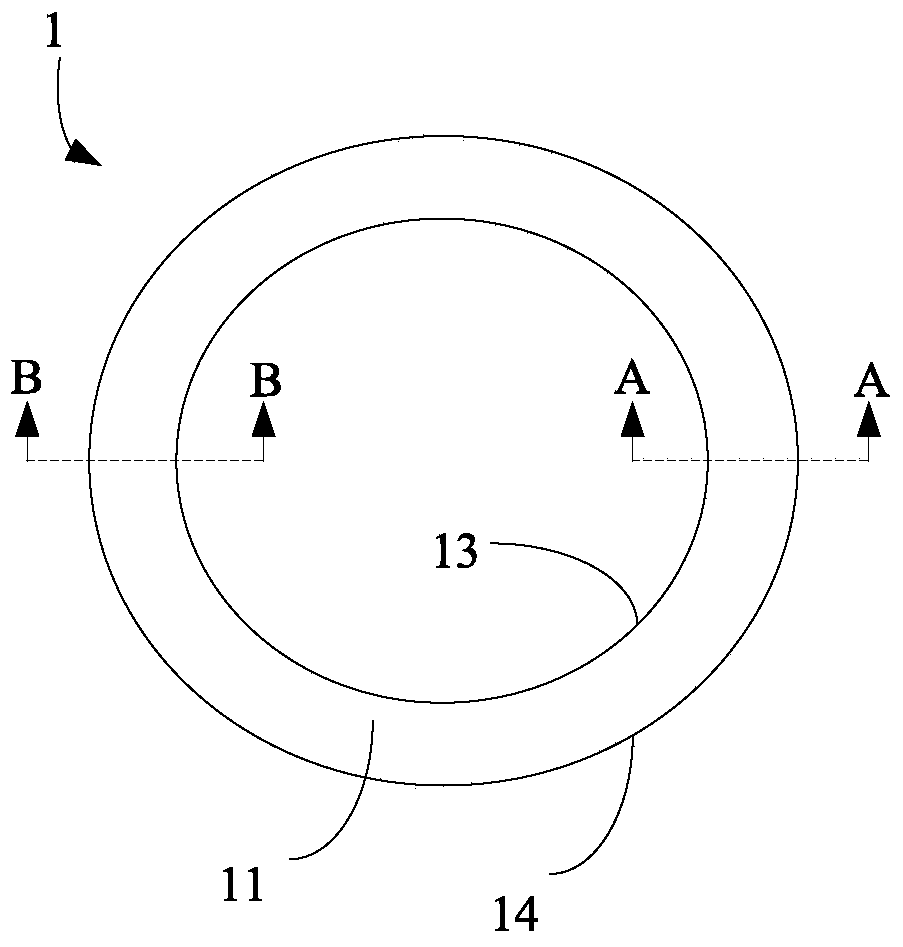

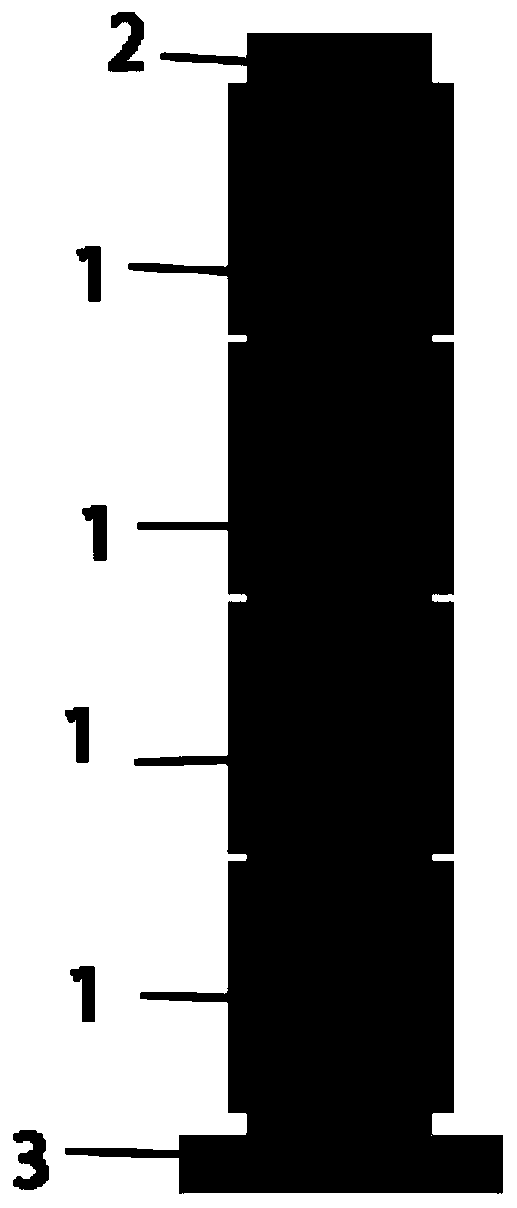

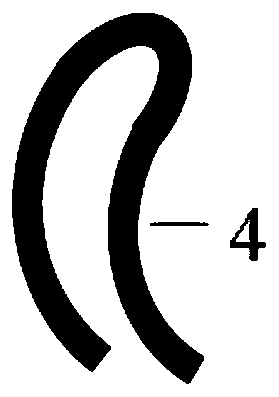

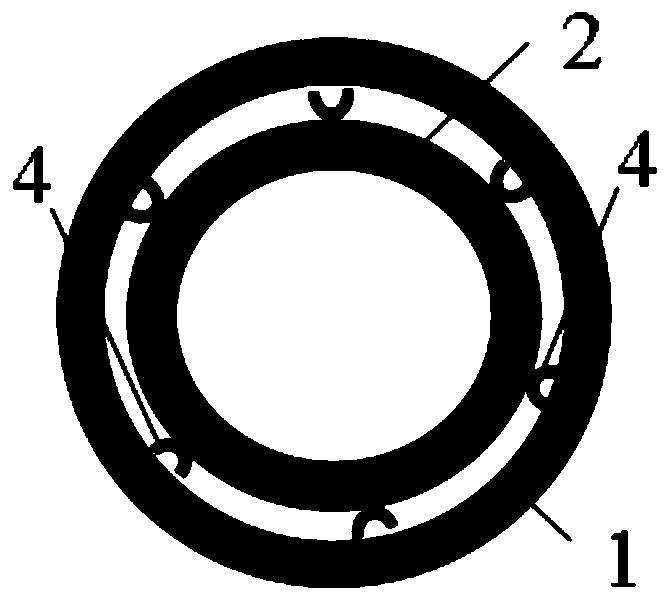

A kind of assembly method of rotating target

ActiveCN111408864BImprove solder joint rateImprove yieldWelding/cutting auxillary devicesVacuum evaporation coatingEngineeringMechanical engineering

The invention provides a method for assembling a rotating target. The method includes: putting at least two rotating targets on the back tube for splicing, forming a splicing gap between two adjacent rotating targets, and setting a plurality of first supports in each of the splicing gaps; A part of each of the first supports is located between the rotating target and the back pipe on one side of the splicing gap, and the other part is located between the rotating target and the back pipe on the other side of the splicing gap; in each of the splicing gaps A second support is set, the second support is ring-shaped, sleeved on the back tube, and separates the two rotating targets forming the rotating target; each of the splicing gaps is sealed with a seal Sealed to obtain the assembled rotating target. The method for assembling the rotating target provided by the present invention can make the obtained assembled rotating target have a high welding bonding rate during welding, a high yield rate, uniform splicing gaps, good surface height consistency of adjacent rotating targets, and no steps on the surface .

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Preparation method of carbon-silicon carbide ceramic target blank

ActiveCN113135756AEfficient weldingImprove solder joint rateCeramic shaping apparatusCarbide siliconCeramic materials

The invention relates to a preparation method of a carbon-silicon carbide ceramic target blank, and the preparation method comprises the following steps: filling carbon-silicon carbide composite powder into a die, carrying out cold pressing, and then sequentially carrying out hot pressing sintering and cooling to obtain the carbon-silicon carbide ceramic target blank. The sphericity degree of particles in the carbon-silicon carbide composite powder is 0.8-1, and the granularity of the particles is 120-180 microns. the hot pressing sintering comprises first heat preservation, second heat preservation, and heat preservation and pressure preservation which are sequentially carried out. The high-performance target blank is prepared by controlling the sphericity and proportion of the raw materials in the preparation process and adopting a pre-cold-pressing mode, good infiltration can be realized when the prepared target blank and a back plate are welded, so that the target material and the back plate can be well welded, the welding binding rate is up to 99% or above, the density can reach 99% or above, and the yield can also reach 98% or above.

Owner:上海戎创铠迅特种材料有限公司

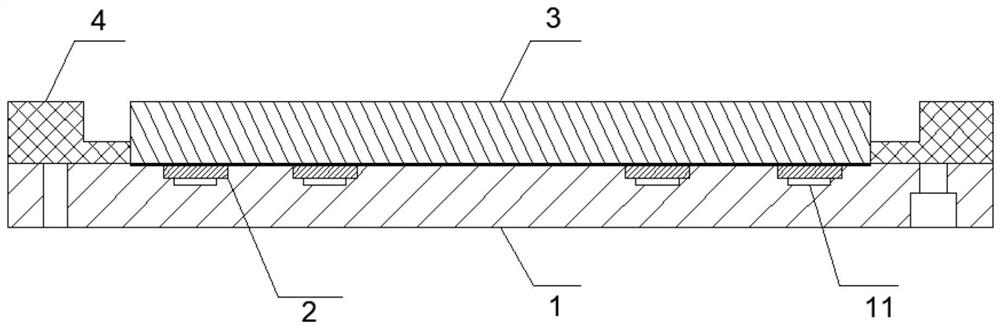

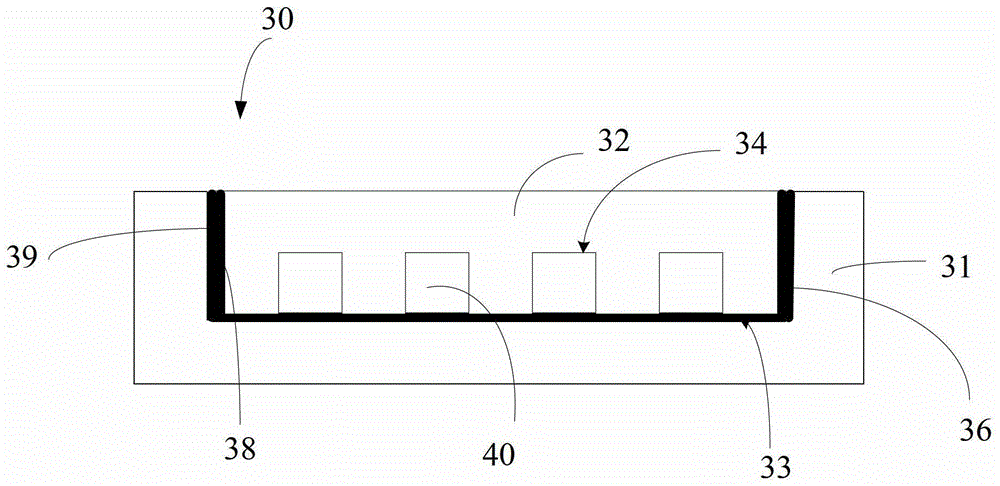

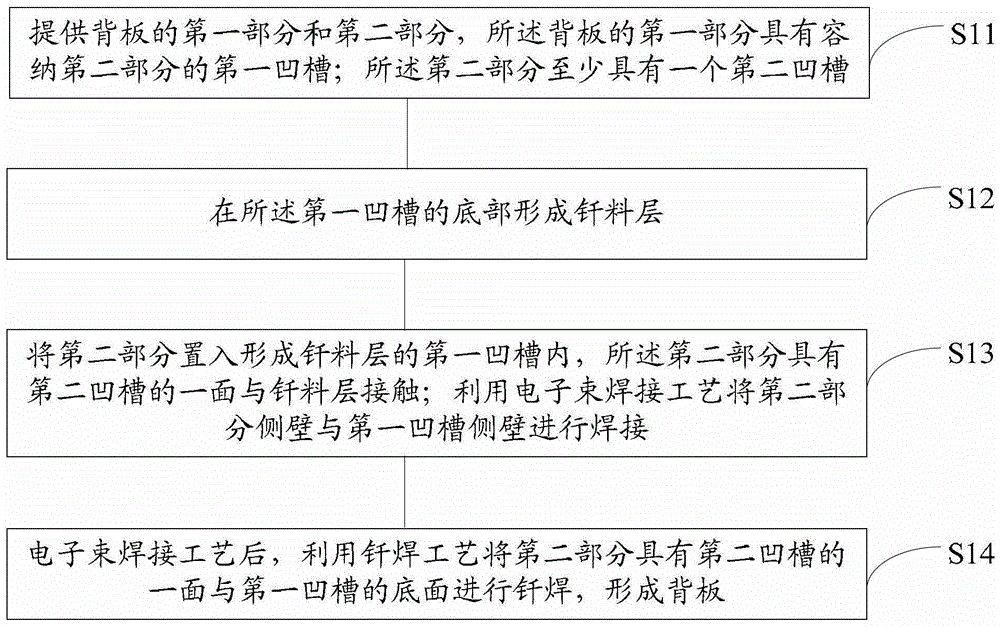

Manufacturing method of backplane and backplane

ActiveCN103785961BImprove solder joint rateEasy to adjustVacuum evaporation coatingSoldering apparatusEngineeringElectron

The invention provides a back plate and a manufacturing method thereof. The manufacturing method includes: providing first and second portions of the back plate; forming a solder layer at the bottom of a first cavity of the first portion; placing the second portion into the first cavity in which the solder layer is formed, and allowing the second cavity side of the second portion to contact with the solder layer; welding the sidewall of the second portion to the sidewall of the first cavity by means of an electron beam welding process; after performing the electron beam welding process, soldering the second cavity side of the second portion to the bottom of the first cavity by means of a soldering process to form the back plate. The first portion is provided with the first cavity used for accommodating the second portion; the second portion is provided with at least one second cavity. The invention further provides the back plate. Through the application of the manufacturing method of the back plate, the service life of the back plate can be prolonged, substrate coating quality can be improved, and the increasing requirements of the sputtering process are met.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Manufacturing method of welding jig and target assembly

ActiveCN105436649BHigh concentricityEasy alignmentWelding/cutting auxillary devicesAuxillary welding devicesWelding processBackplane

The invention discloses a welding jig and a manufacturing method for a target assembly. The manufacturing method for the target assembly includes the steps that a target, a back plate and the welding jig are provided; a first solder layer is formed on a face to be welded of the target through solder; a second solder layer is formed on a face to be welded of the back plate through solder; the target with the first solder layer and the back plate with the second solder layer are fixed to the welding jig; and the first solder layer and the second solder layer are combined through a welding process, so that the target assembly is formed. According to the target assembly formed by the manufacturing method for the target assembly, the requirements for stably producing and using the ceramic target for a long time can be met, and the service life of the target assembly can be greatly prolonged.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Diffusion welding method for molybdenum target material and back plate

PendingCN113275731AImprove solder joint rateSolve the problem of poor weldingNon-electric welding apparatusHot isostatic pressingAluminium alloy

The invention provides a diffusion welding method for a molybdenum target material and a back plate. The welding method comprises the following steps that turning end surface thread and step end surface thread treatment is performed on a welding surface of the molybdenum target material; step concave groove machining treatment is carried out on the back plate; ultrasonic cleaning and drying treatment is performed on the welding surface of the molybdenum target material; and the molybdenum target material and the back plate are assembled, and sheath welding, degassing and hot isostatic pressing welding are sequentially carried out. According to the method, the problem of poor welding of the molybdenum target material with the copper alloy back plate and the aluminum alloy back plate is solved, and the welding binding rate of the molybdenum target, the copper alloy back plate and the aluminum alloy back plate is increased.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

A welding method of wti target material and copper back plate

ActiveCN111843161BImprove welding effectImprove solder joint rateWelding/soldering/cutting articlesNon-electric welding apparatusEngineeringCopper

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Target assembly and method of manufacturing the same

ActiveCN104416281BEasy dischargeAvoid residueVacuum evaporation coatingSputtering coatingEngineeringMechanical engineering

The invention discloses a manufacturing method for a target assembly. The manufacturing method comprises the following steps: providing a target and a back plate; processing a welding surface of the target, processing a first welding plane in a central region of the welding surface of the target, and processing a second welding plane around the first welding plane, wherein the first welding plane is protruded relative to the second welding plane; processing a welding surface of the back plate to enable the thickness of the back plate to be gradually reduced from the center to the surrounding; welding the target and the back plate together; removing part of a material of the target and part of a material of the back plate so as to form the target assembly. The invention also provides a target assembly. The target assembly comprises the target and the back plate; the welding surface of the target is embedded into the welding surface of the back plate. According to the method provided by the invention, retained gas between the target and the back plate is further exhausted, so that the target yield is increased. Furthermore, the invention also provides the target assembly obtained by the method.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

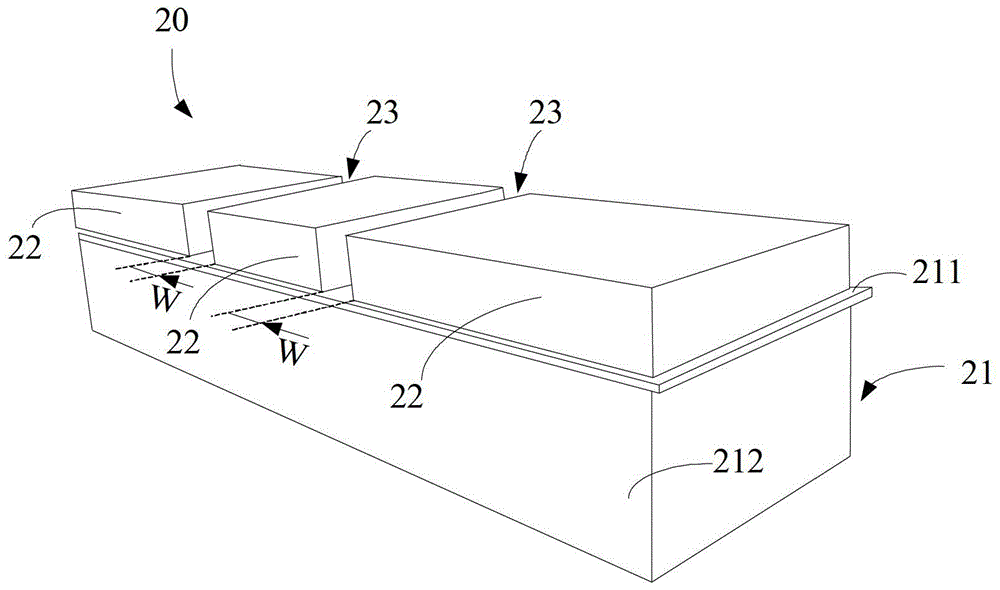

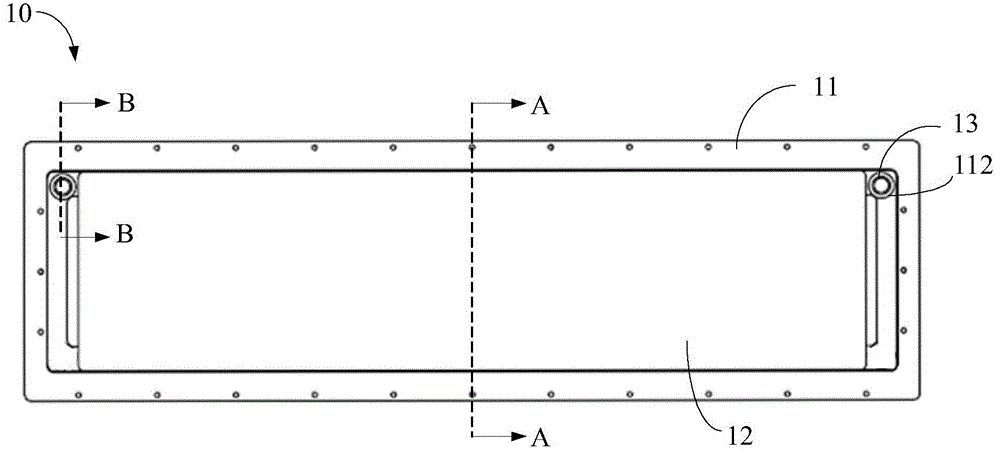

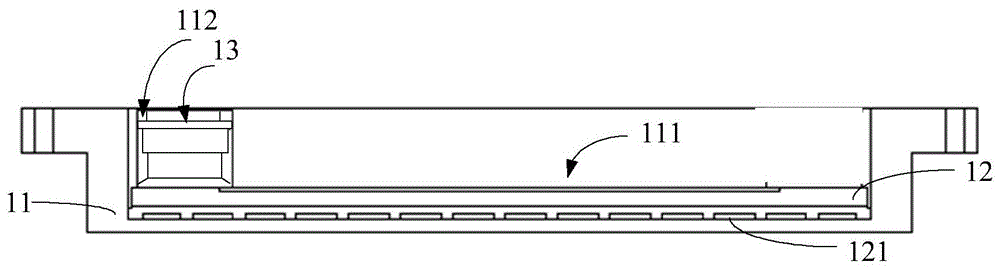

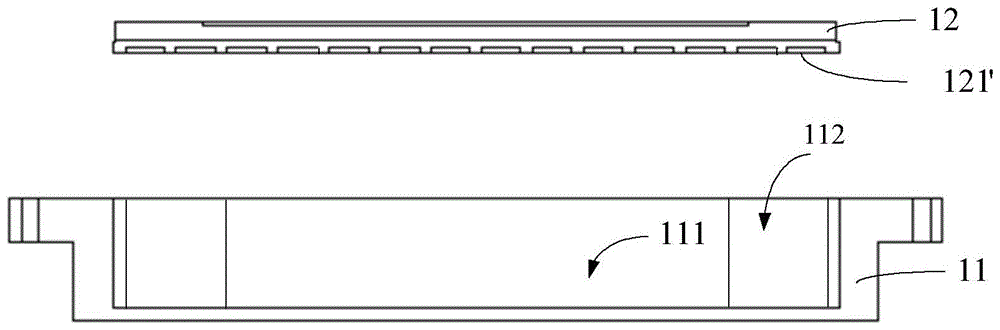

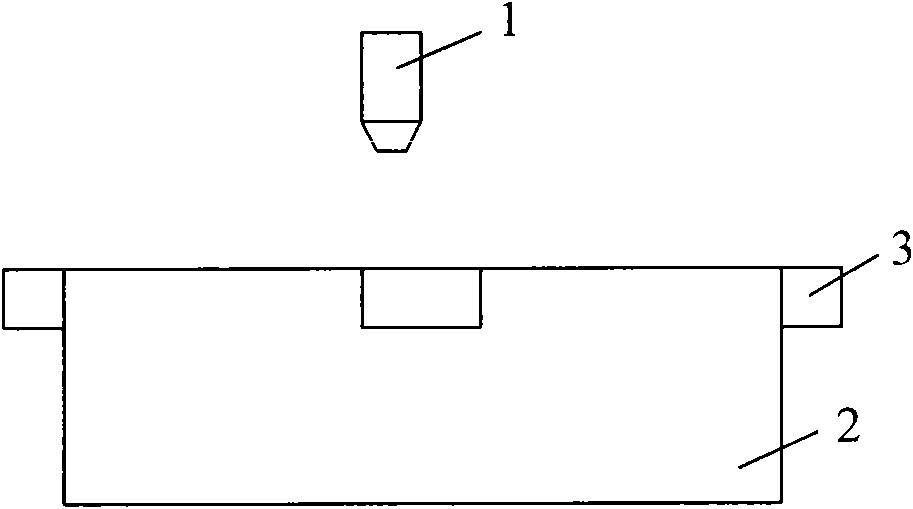

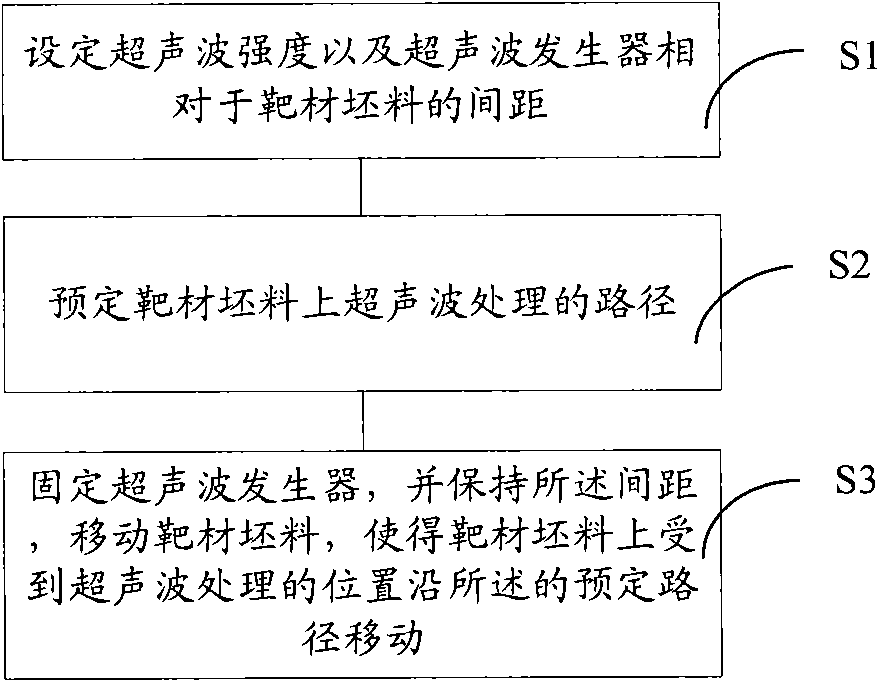

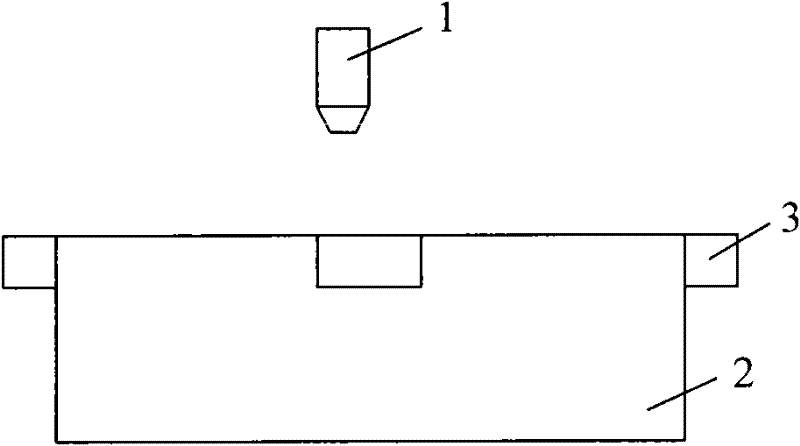

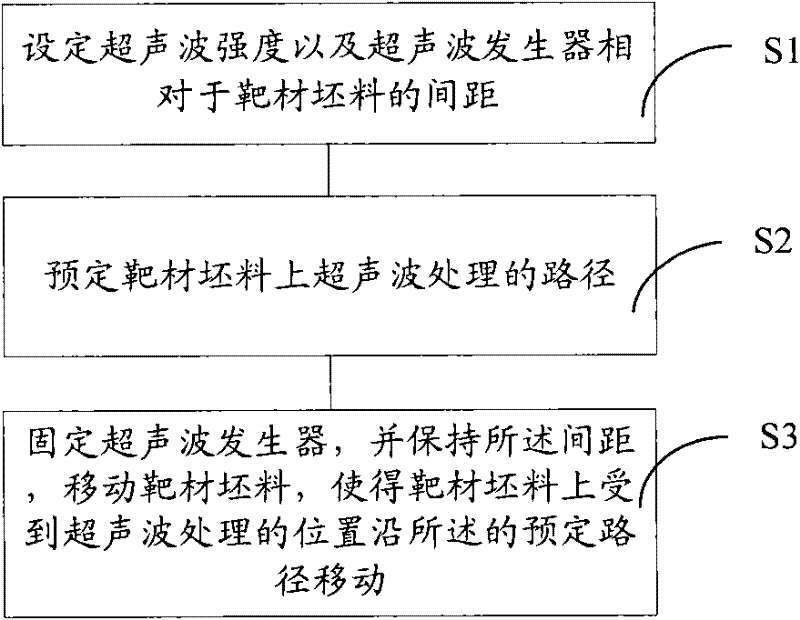

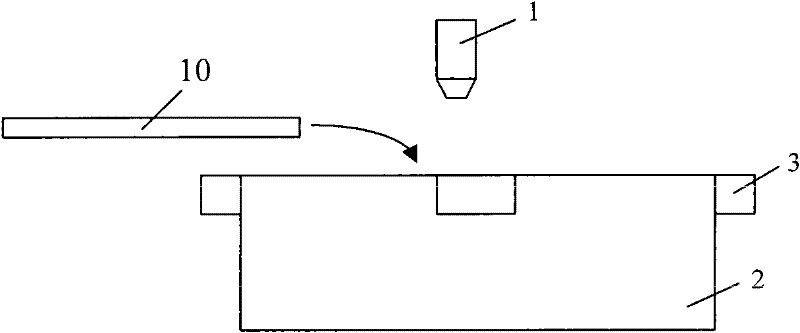

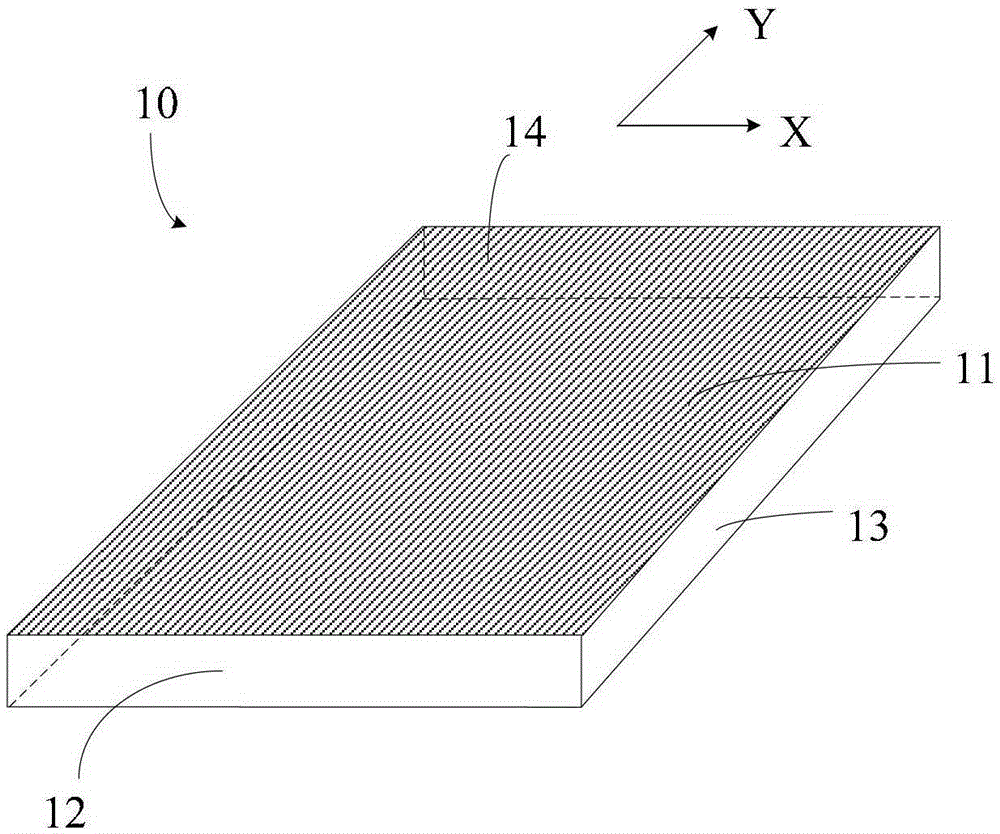

Large-size target ultrasonic treatment device and treatment method thereof

ActiveCN101768723AConsistency and stabilityGuarantee the quality of ultrasonic treatmentVacuum evaporation coatingSputtering coatingEngineeringTherapeutic effect

The invention discloses a large-size target ultrasonic treatment device and a treatment method thereof. The device comprises an ultrasonic generator, a target blank bearing table and a driving device, wherein the ultrasonic generator is used for generating and transmitting ultrasound waves; the target blank bearing table is used for bearing target blanks and aligning with the ultrasonic generator; and the driving device is arranged on the target blank bearing table and used for moving the target blanks. The driving device can move the target blanks relative to the ultrasonic generator and keep the space between the target blanks and the ultrasonic generator consistent. The invention can stabilize the consistency of the ultrasonic treatment effect while ensuring the ultrasonic treatment quality without repeatedly treating the surfaces of the blanks, and improve the production efficiency.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Assembling method for rotating target material

ActiveCN111408864AImprove solder joint rateImprove yieldVacuum evaporation coatingWelding/cutting auxillary devicesPhysicsEngineering

The invention provides an assembling method for a rotating target material. The method comprises the steps that at least two rotating target material bodies are arranged on a back pipe in a sleeving mode to be spliced, a splicing gap is formed between every two adjacent rotating target material bodies, and multiple first supporting pieces are arranged in each splicing gap; one part of each first supporting piece is located between the rotating target material body on one side of the splicing gap and the back pipe, and the other part of each first supporting piece is located between the rotating target material body on the other side of the splicing gap and the back pipe; a second supporting piece is arranged in each splicing gap, the second supporting pieces are annular and arranged on theback pipe in a sleeving mode so as to separate the two rotating target material bodies forming the rotating target material; and each splicing gap is sealed through a sealing piece so as to obtain the assembled rotating target material. According to the assembling method for the rotating target material, the obtained assembled rotating target material is high in welding bonding rate, high in finished product rate and uniform in splicing gap during welding, the surface height consistency of the adjacent rotating target material bodies is good, and no step exists on surfaces.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Large-size target ultrasonic treatment device and treatment method thereof

ActiveCN101768723BConsistency and stabilityGuarantee the quality of ultrasonic treatmentVacuum evaporation coatingSputtering coatingTherapeutic effectEngineering

The invention discloses a large-size target ultrasonic treatment device and a treatment method thereof. The device comprises an ultrasonic generator, a target blank bearing table and a driving device, wherein the ultrasonic generator is used for generating and transmitting ultrasound waves; the target blank bearing table is used for bearing target blanks and aligning with the ultrasonic generator; and the driving device is arranged on the target blank bearing table and used for moving the target blanks. The driving device can move the target blanks relative to the ultrasonic generator and keep the space between the target blanks and the ultrasonic generator consistent. The invention can stabilize the consistency of the ultrasonic treatment effect while ensuring the ultrasonic treatment quality without repeatedly treating the surfaces of the blanks, and improve the production efficiency.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Target assembly welding method

ActiveCN103658898BReduce tensile stressReduce decreaseSoldering auxillary devicesEngineeringFiller metal

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Method of forming the backplane

ActiveCN104668897BConducive to the formation of segregationHigh hardnessVacuum evaporation coatingSputtering coatingEngineering

Disclosed is a method for forming a back plate. The method includes that a first bottom plate blank and a first cover plate blank are provided; the first bottom plate blank is subjected to forging to form a second bottom plate blank; the first cover plate blank is subjected to forging to form a second cover plate blank; the second bottom plate blank is subjected to annealing to form a bottom plate; the second cover plate blank is subjected to annealing to form a cover plate; the bottom plate and the cover plate are welded to form the back plate. By means of the method for forming the back plate, the back plate can be applied to a magnetron sputtering process, qualities of films formed on a substrate can be improved, and costs of the magnetron sputtering process are lowered.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

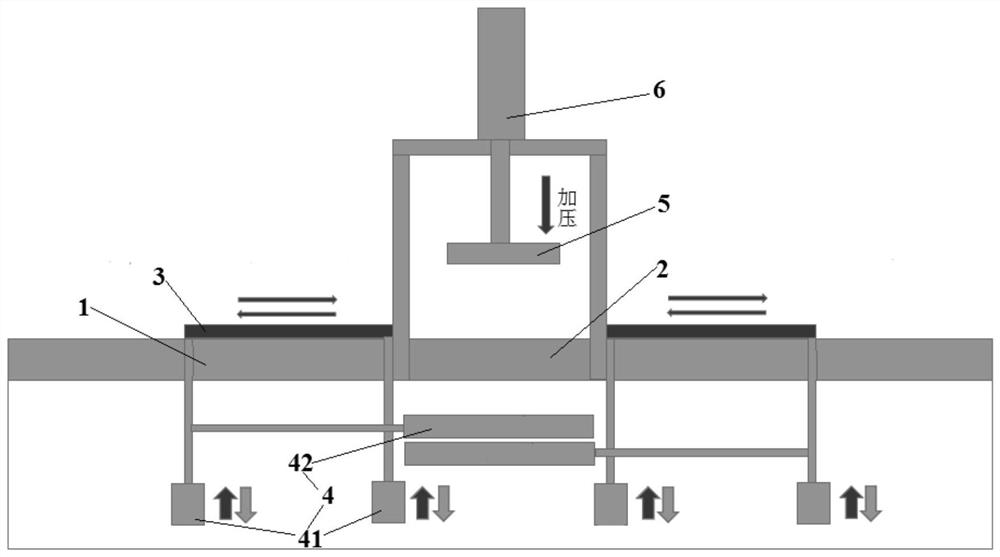

Target welding and cooling integrated device and operation method thereof

InactiveCN112427762ARealize welding heatingRealize automatic handlingMetal working apparatusSoldering auxillary devicesEngineeringIntegrated devices

The invention provides a target welding and cooling integrated device and an operation method thereof. The integrated device comprises a welding platform and a cooling platform, wherein the welding platform and the cooling platform are located on the same plane, a movable heating plate is arranged on the welding platform, and a transmission assembly is connected to the lower portion of the movableheating plate. The transmission assembly comprises a vertically-moving transmission assembly body and a horizontally-moving transmission assembly body. A pressurizing assembly is arranged above the cooling platform. According to the integrated device, the welding platform and the cooling platform are integrated in the same device, welding heating, automatic carrying and pressurizing cooling of atarget assembly can be integrally achieved, manual carrying is omitted, abnormal welding faces caused by vibration possibly occurring in the manual carrying process are avoided, the welding combination rate is high, and the potential safety hazard in the carrying process is reduced; and the device can automatically operate, welding and cooling of the target assembly can be rapidly achieved, time is saved, and cost is reduced.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Manufacturing method of target assembly

ActiveCN107570905BImprove solder joint rateImprove wettabilityVacuum evaporation coatingSputtering coatingCopperWelding process

The invention provides a manufacture method of a target material assembly. The method comprises the following steps: providing a copper target blank and a back board, wherein a to-be-welded surface ofthe copper target blank is a first welding surface and a to-be-welded surface of the back board is a second welding surface; coating the first welding surface with a first solder layer, the materialof which is used recovery material; coating the first solder layer with a second solder layer, the material of which is not used, wherein the second solder layer and the first solder layer are the same in material; enabling the first welding surface coated with the first solder layer and the second welding surface coated with the second solder layer to be oppositely arranged and attached with eachother, welding the target blank to the back board by welding technology in order to form the target material assembly. The material of the first solder layer is used recovery material while the material of the second solder layer is not used. Compared with a scheme adopting only one solder layer, welding bonding efficiency of the target blank and the back board can be increased after mutual fusion between the first solder layer and the second solder layer.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Brazing method for high-purity aluminum target assembly and high-purity aluminum target assembly

ActiveCN112059345BNot easy to fall offImprove solder joint rateMetal working apparatusSoldering auxillary devicesWater leakWelding process

The present invention provides a brazing method for a high-purity aluminum target assembly and a high-purity aluminum target assembly. The brazing method for the high-purity aluminum target assembly includes arranging grooves in the high-purity aluminum target and placing a groove on the back plate. The boss is set on the top, and the back plate made of C18150 or C18000 is selected, which can not only ensure the welding bonding rate of the back plate and the high-purity aluminum target, but also can effectively surface the deformation during the welding process, and the high-purity aluminum after welding. The target component has no water leakage, and the application prospect is excellent.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com