Target material assembly as well as preparation method and application thereof

A target and component technology, which is applied in the field of sputtering targets, can solve the problems of low bonding strength, cracking, and brittle joints between the target and the back plate, and achieve good industrial application prospects, simple process flow, and reduced difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

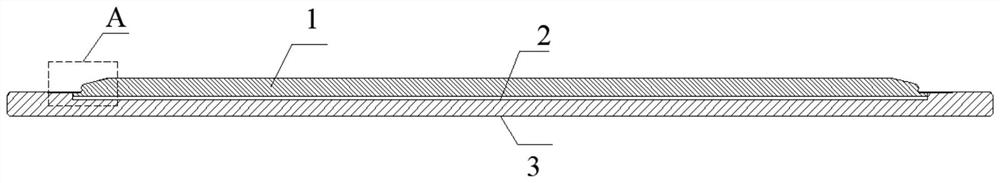

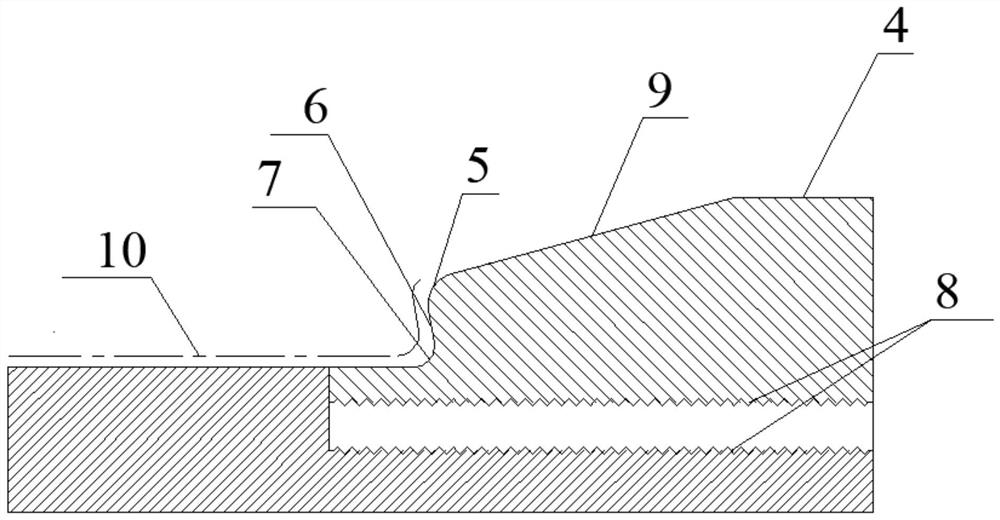

[0075] This embodiment provides a target assembly and its preparation method, the schematic diagram of the front view structure of the target assembly is as follows figure 1 As shown, the enlarged picture of circle A is shown in figure 2 shown.

[0076] The target assembly includes a target body 1, an intermediate layer 2, and a target back plate 3 connected to the target body 1 through the intermediate layer 2; the target body 1 is titanium with an electrical conductivity of 3 ms / m Aluminum alloy (Ti-50at%Al) with a diameter of 454mm; the middle layer 2 is A1060 aluminum, and the target back plate 3 is A6061 aluminum with a conductivity of 24ms / m, with a diameter of 524mm.

[0077] The target body 1 includes a sputtering surface 4, a main body side 6 connected to the sputtering surface 4 through a first chamfer 5, a main body sandblasting surface connected to the main body side 6 through a second chamfer 7, and The welding surface opposite to the sputtering surface 4; the ...

Embodiment 2

[0087] This embodiment provides a target assembly and its preparation method. The target assembly includes a target body 1, an intermediate layer 2, and a target back plate 3 connected to the target body 1 through the intermediate layer 2. The target body 1 is titanium-aluminum alloy (Ti-50at%Al) with a conductivity of 5ms / m and a diameter of 454mm; the middle layer 2 is A1060 aluminum, and the target back plate 3 is A6061 with a conductivity of 26ms / m Aluminum with a diameter of 524mm.

[0088] The target body 1 includes a sputtering surface 4, a main body side 6 connected to the sputtering surface 4 through a first chamfer 5, a main body sandblasting surface connected to the main body side 6 through a second chamfer 7, and The welding surface opposite to the sputtering surface 4; the radius of the first chamfer 5 is 1.2mm, and the radius of the second chamfer 7 is 0.8mm;

[0089] The edge of the sputtering surface 4 of the target body 1 is provided with a radially outward a...

Embodiment 3

[0098] This embodiment provides a target assembly and its preparation method. The target assembly includes a target body 1, an intermediate layer 2, and a target back plate 3 connected to the target body 1 through the intermediate layer 2. ; The target body 1 is titanium-aluminum alloy (Ti-50at%Al) with a conductivity of 4ms / m and a diameter of 454mm; the middle layer 2 is A1060 aluminum, and the target back plate 3 is A6061 with a conductivity of 25ms / m Aluminum with a diameter of 524mm.

[0099] The target body 1 includes a sputtering surface 4, a main body side 6 connected to the sputtering surface 4 through a first chamfer 5, a main body sandblasting surface connected to the main body side 6 through a second chamfer 7, and The welding surface opposite to the sputtering surface 4; the radius of the first chamfer 5 is 1.7mm, and the radius of the second chamfer 7 is 1.2mm;

[0100] The edge of the sputtering surface 4 of the target body 1 is provided with a radially outward...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com