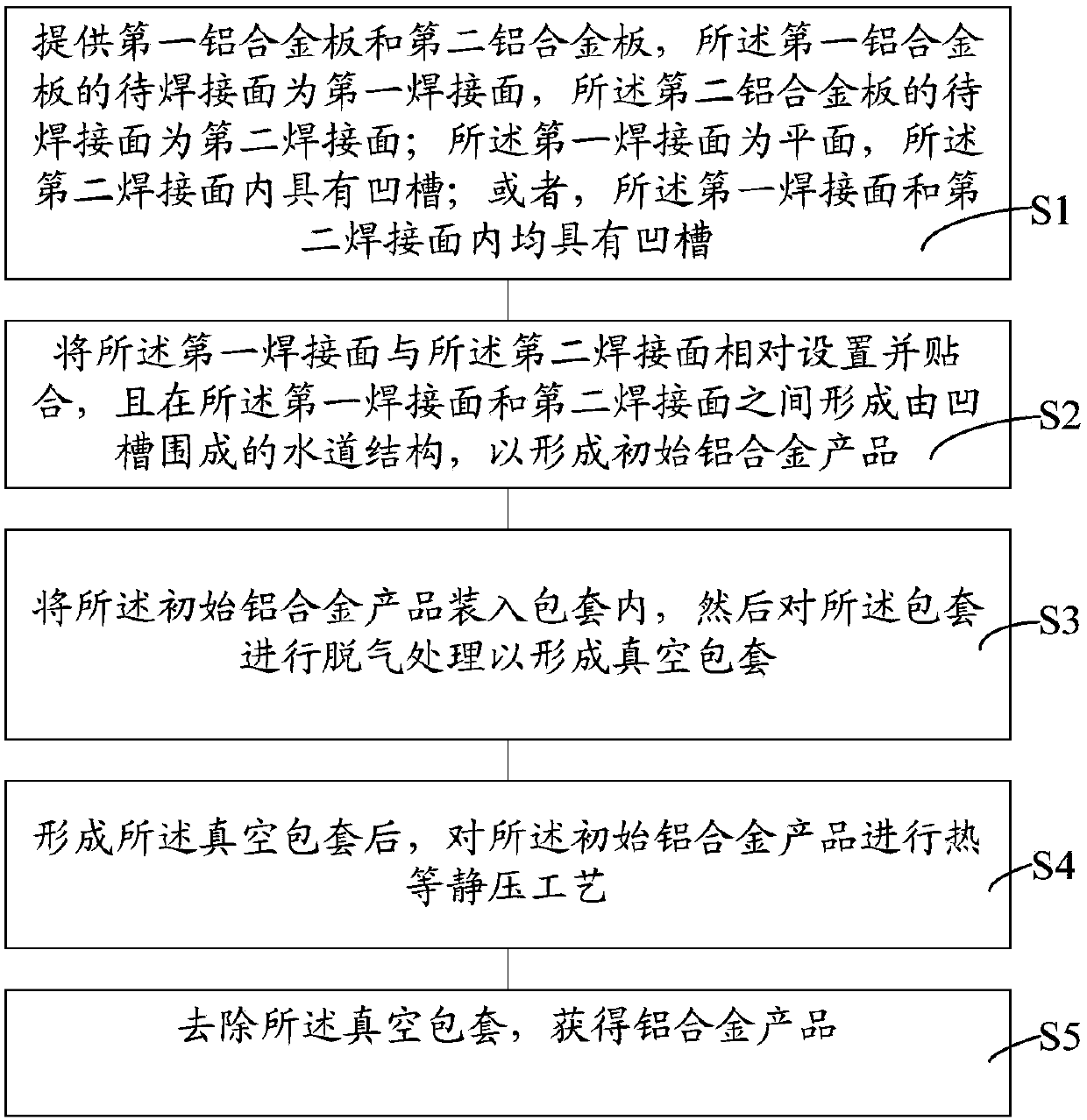

Manufacturing method of aluminum alloy product

A technology for aluminum alloy products and manufacturing methods, which is applied in manufacturing tools, metal processing equipment, non-electric welding equipment, etc., can solve the problem of improving the yield rate of aluminum alloy products, avoid deformation or even blockage, avoid desoldering, and improve good quality. rate and performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It can be seen from the background art that the yield rate of aluminum alloy products needs to be improved. Analyze the reasons for this:

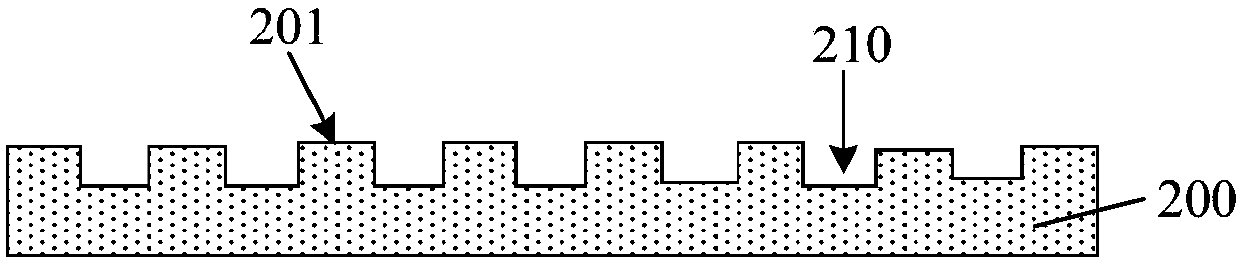

[0028] In order to achieve good high-temperature deformation resistance of 6061 aluminum alloy products, complex water channel structure design is adopted inside. During the use of the 6061 aluminum alloy product, continuous cooling water flows into the water channel structure, thereby taking away a large amount of heat from the surface of the product.

[0029] Among them, the welding of 6061 aluminum alloy products usually adopts methods such as vacuum brazing, molten lead welding, intermediate layer connection welding and liquid phase diffusion welding. The 6061 aluminum alloy product formed by the above welding method, when the welding strength of the formed aluminum alloy product is high, it is easy to cause deformation or even blockage of the water channel structure, resulting in insufficient water flow, affecting the heat dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface finish | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com