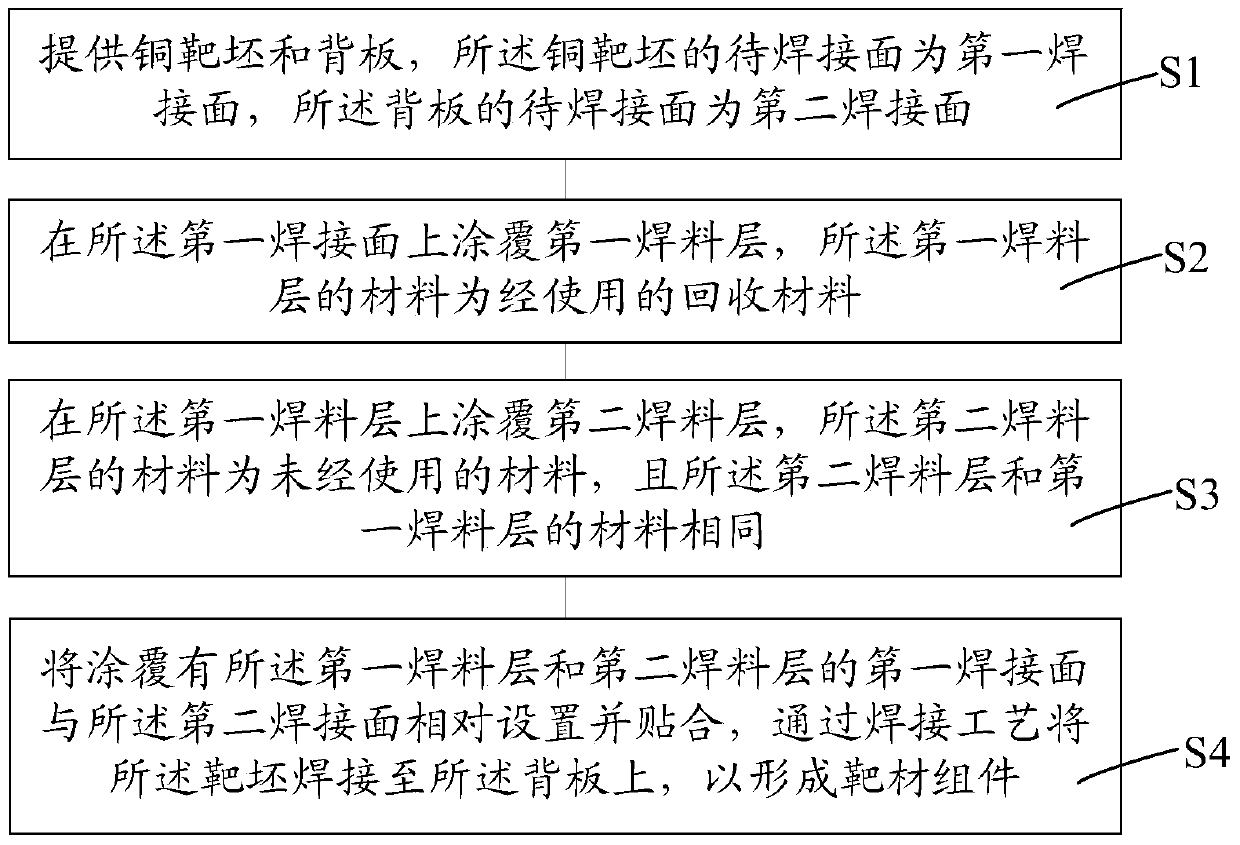

Manufacturing method of target assembly

A manufacturing method and component technology, which is applied in the direction of manufacturing tools, metal material coating process, vacuum evaporation plating, etc., can solve the problems such as the need to improve the welding bonding rate of target components, the damage of sputtering pedestal, and the influence of film formation quality , to avoid the decline of welding effect, improve the welding bonding rate, and improve the effect of wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

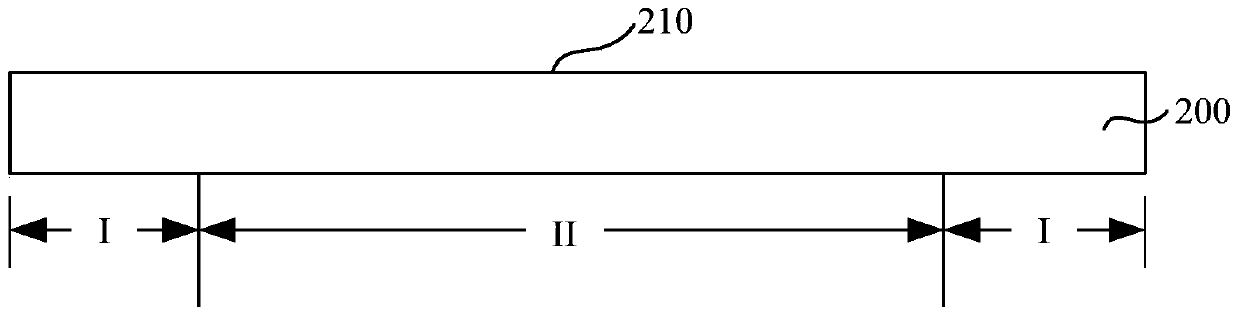

[0031] It can be seen from the background art that a target assembly is generally composed of a target blank that meets the sputtering performance and a back plate that is combined with the target blank and has a certain strength.

[0032] For the target assembly composed of ultra-high-purity copper target blank and copper back plate, brazing process is mainly used to realize the welding of target blank and back plate at present. The brazing process is to use solder whose melting point is lower than the melting point of the target blank and the back plate, and heat the target blank and the back plate at a temperature lower than the melting point of the target blank and the back plate and higher than the melting point of the solder, and wait for the solder to melt. , so that the surface to be welded of the target blank and the surface to be welded of the back plate are relatively arranged and bonded, and the solder diffuses with the target blank and the back plate to form a weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com