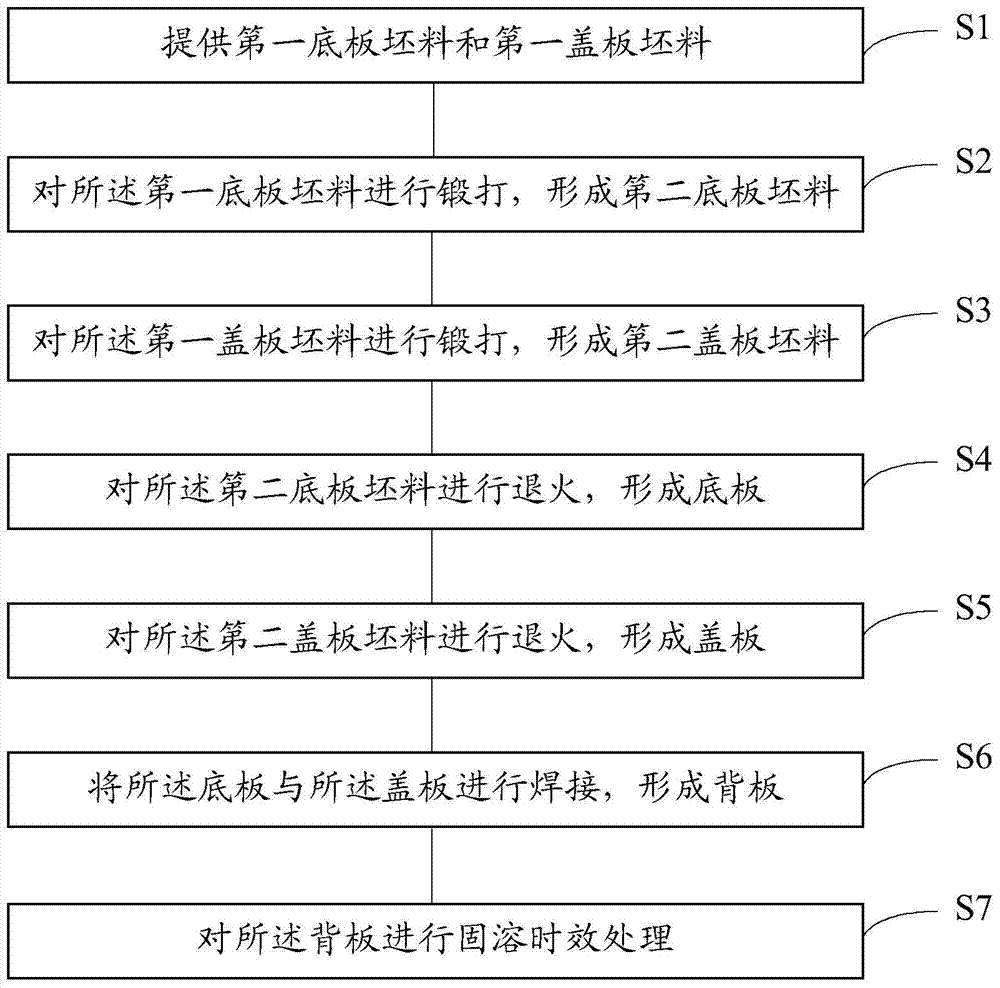

Method of forming the backplane

A backplane and bottom plate technology, applied in the field of backplane formation, can solve the problems of high cost of magnetron sputtering process, low film quality, etc., to avoid uneven bombardment, improve film quality, and improve utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] After discovery and analysis, when the backplane formed by the method of the prior art is applied to the magnetron sputtering process, the quality of the film layer formed on the substrate is not high, and the reasons for the high cost of the magnetron sputtering process are as follows: (1) Using current technology The hardness of the back plate formed by the technical method is at most 100HV. Because the hardness of the back plate is not enough, the deformation rate will increase when it is applied in the magnetron sputtering process, which will cause uneven bombardment of the target, thus affecting the film formed on the substrate. layer quality. The uneven bombardment phenomenon will also reduce the utilization rate of the target material, thereby increasing the process cost. (2) The welding bonding rate of the back plate formed by the method of the prior art is not high. When the back plate is applied to the magnetron sputtering process, it is easy to cause the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com