Brazing method for high-purity aluminum target assembly and high-purity aluminum target assembly

A brazing method and aluminum target technology, which is applied in the field of target welding and sputtering targets, can solve the problems of easy deformation of target components and target deformation, and achieve the advantages of small deformation, not easy to fall off, and high product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment provides a brazing method for a high-purity aluminum target assembly, and the brazing method includes the following steps:

[0063] (1') Polishing the welding surface of the high-purity aluminum target (99.999wt%) and the welding surface of the backing plate until the roughness Ra of the welding surface of the high-purity aluminum target is 0.4 μm, and the welding surface of the backing plate has a roughness Ra of 0.4 μm. The roughness is 0.4μm;

[0064] (2') The solder is placed in the groove of the high-purity aluminum target, and after assembling the high-purity aluminum target and the back plate, brazing and welding are performed at 240 ° C to obtain a welded assembly;

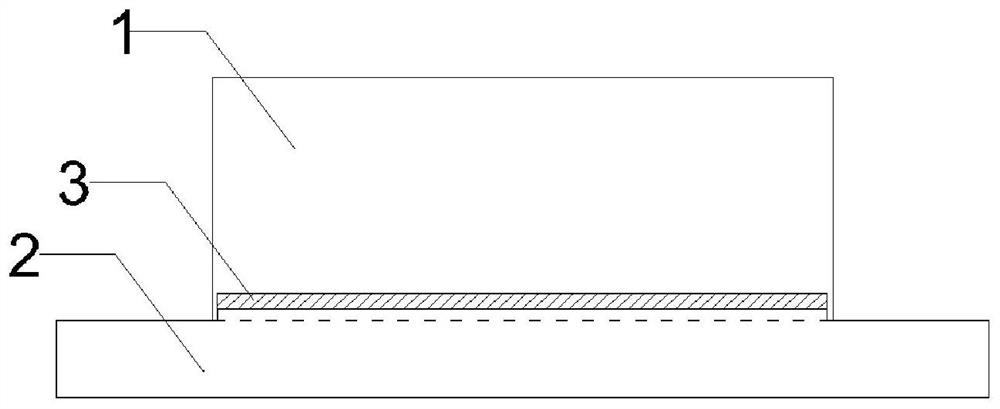

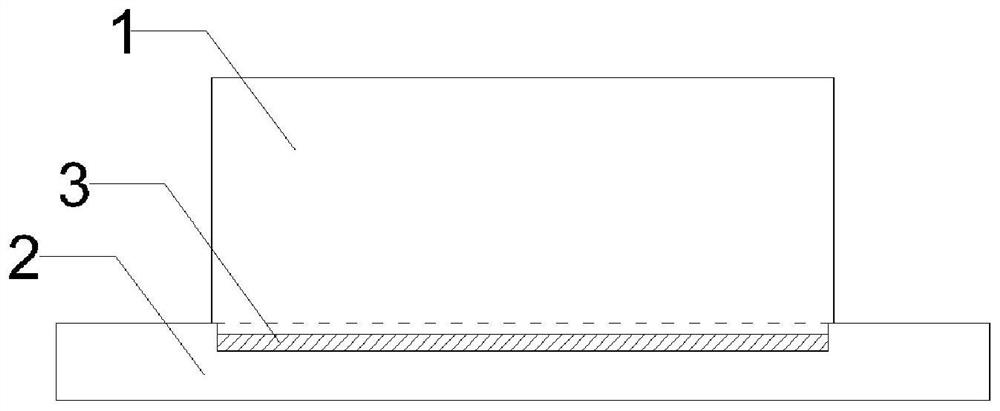

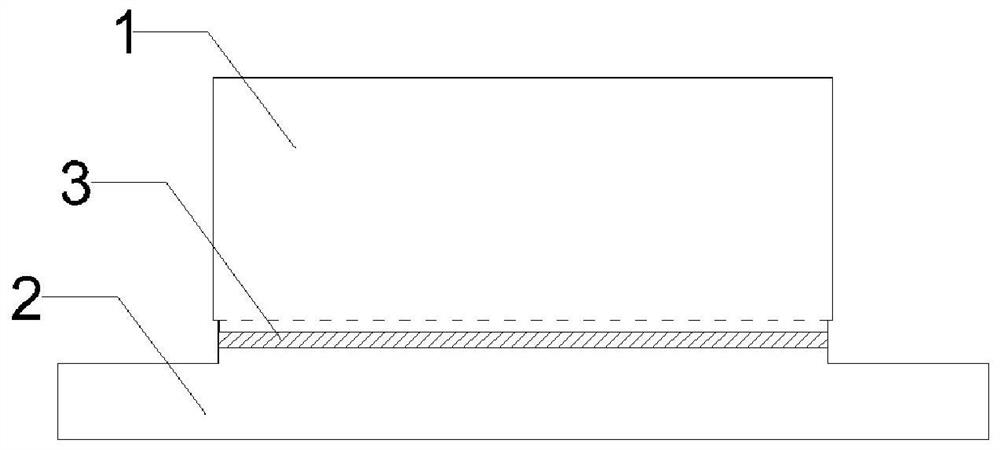

[0065] Wherein, the material of the back plate is C18000, such as figure 1 As shown, the back plate 2 includes a base and a boss arranged on the welding surface of the base; the welding surface of the high-purity aluminum target 1 is provided with a groove; the diameter of the groov...

Embodiment 2

[0068] This embodiment provides a brazing method for a high-purity aluminum target assembly, and the brazing method includes the following steps:

[0069] (1') Polishing the welding surface of the high-purity aluminum target (99.9995wt%) and the welding surface of the back plate until the roughness Ra of the welding surface of the high-purity aluminum target is 1.5 μm, and the welding surface of the back plate is The roughness is 0.8μm;

[0070] (2') The solder is placed in the groove of the high-purity aluminum target, and after assembling the high-purity aluminum target and the back plate, brazing and welding are performed at 200 ° C to obtain a welded assembly;

[0071] Wherein, the material of the back plate is C18000, the back plate includes a base and a boss arranged on the welding surface of the base; the welding surface of the high-purity aluminum target is provided with a groove; the diameter of the groove is larger than The diameter of the boss is 0.01mm larger; the...

Embodiment 3

[0074] This embodiment provides a brazing method for a high-purity aluminum target assembly, and the brazing method includes the following steps:

[0075] (1') Polishing the welding surface of the high-purity aluminum target (99.99 wt %) and the welding surface of the backing plate until the roughness Ra of the welding surface of the high-purity aluminum target is 0.8 μm, and the welding surface of the backing plate has a roughness Ra of 0.8 μm. The roughness is 0.5μm;

[0076] (2') The solder is placed in the groove of the high-purity aluminum target, and after assembling the high-purity aluminum target and the back plate, brazing and welding are performed at 190 ° C to obtain a welded assembly;

[0077] Wherein, the material of the back plate is C18000, the back plate includes a base and a boss arranged on the welding surface of the base; the welding surface of the high-purity aluminum target is provided with a groove; the diameter of the groove is larger than The diameter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com