Large-size target ultrasonic treatment device and treatment method thereof

A large-size target and processing device technology, applied in auxiliary devices, metal material coating process, ion implantation plating and other directions, can solve the problem of inconsistent surface treatment effect of blanks, etc. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

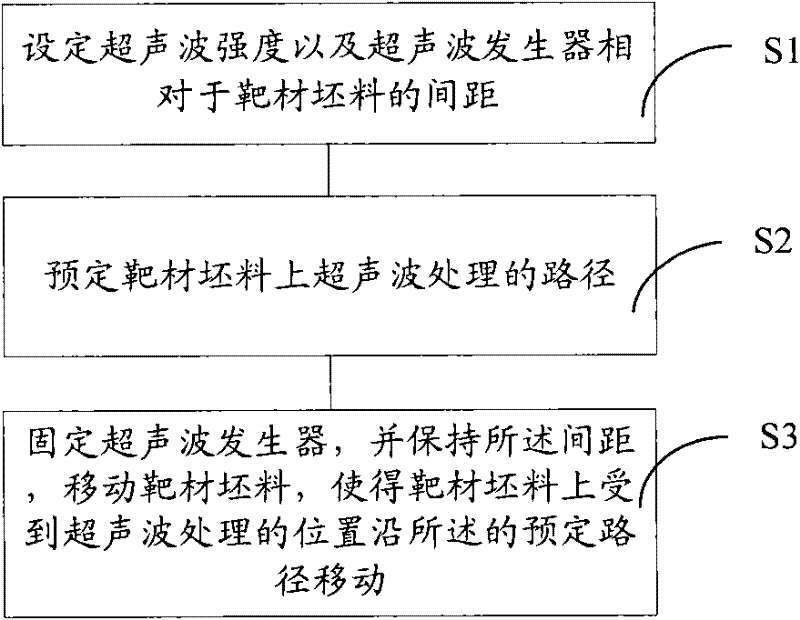

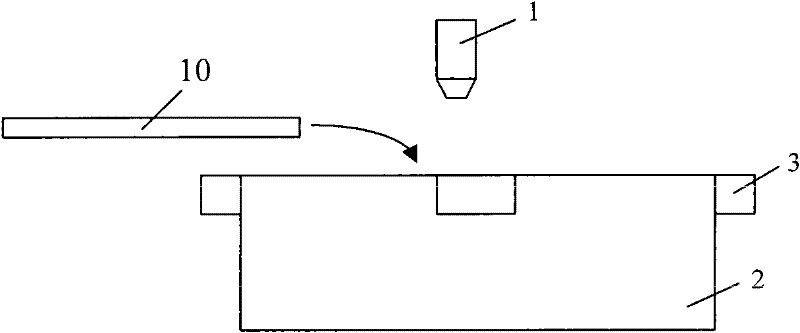

[0023] According to the background technology, the existing ultrasonic treatment process is to scan the surface of the target blank by moving the ultrasonic generator, and because the structure of the ultrasonic generator is relatively complicated, it is difficult to keep the distance between the blank and the blank during the moving process. The consistency of the ultrasonic treatment effect on the surface of the target blank is affected, and repeated surface ultrasonic treatment is required, which reduces the production efficiency. The present invention solves the above-mentioned problems by fixing the sonotrode and moving the target blank relative to the sonotrode. Since the structure of the target blank is generally a square or circular plate-like structure, it is easier to move the target blank while maintaining its distance from the sonotrode.

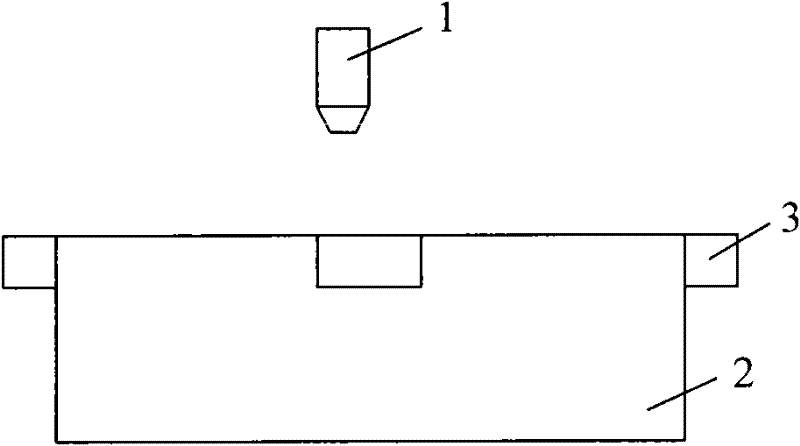

[0024] Based on the above ideas, figure 1 A schematic diagram of a large-size target ultrasonic treatment device provided by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com