Target welding and cooling integrated device and operation method thereof

An operation method and target technology, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve the problems of difficult transfer, difficult to form a stable and uniform solder layer, etc., to reduce costs, avoid abnormal welding surfaces, and reduce safety. hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

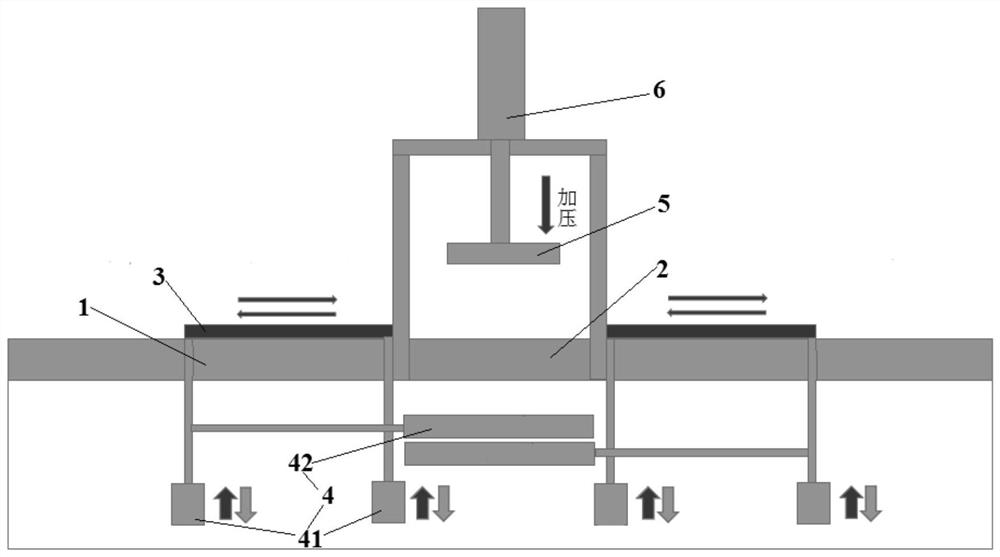

[0068] This embodiment provides an integrated device for target welding and cooling. The structure diagram of the integrated device is as follows: figure 1 As shown, it includes a welding platform 1 and a cooling platform 2, and the welding platform 1 and the cooling platform 2 are located on the same plane; the welding platform 1 is provided with a movable heating plate 3, and the lower part of the movable heating plate 3 is connected with a transmission Assembly 4, the transmission assembly includes a transmission assembly 41 that moves up and down and a transmission assembly 42 that moves horizontally; a pressurizing assembly is provided above the cooling platform 2 .

[0069] There are two welding platforms 1 , and the cooling platform 2 is located between the two welding platforms 1 .

[0070] Each of the welding platforms 1 is provided with a movable heating plate 3 ; each of the welding platforms 1 corresponds to a group of transmission assemblies 4 .

[0071] The mate...

Embodiment 2

[0079] This embodiment provides an integrated device for target welding and cooling, the integrated device includes a welding platform 1 and a cooling platform 2, and the welding platform 1 and the cooling platform 2 are located on the same plane; A movable heating plate 3 is provided, and a transmission assembly 4 is connected below the movable heating plate 3, and the transmission assembly includes a transmission assembly 41 that moves up and down and a transmission assembly 42 that moves horizontally; components.

[0080] There are two welding platforms 1 , and the cooling platform 2 is located between the two welding platforms 1 .

[0081] Each of the welding platforms 1 is provided with a movable heating plate 3 ; each of the welding platforms 1 corresponds to a group of transmission assemblies 4 .

[0082] The material of the moving heating plate 3 is 316 stainless steel.

[0083] The movable heating plate 3 is provided with a target material and a back plate whose wel...

Embodiment 3

[0090] This embodiment provides an integrated device for target welding and cooling, the integrated device includes a welding platform 1 and a cooling platform 2, and the welding platform 1 and the cooling platform 2 are located on the same plane; A movable heating plate 3 is provided, and a transmission assembly 4 is connected below the movable heating plate 3, and the transmission assembly includes a transmission assembly 41 that moves up and down and a transmission assembly 42 that moves horizontally; components.

[0091] The welding platform 1 is provided with one.

[0092] The material of the moving heating plate 3 is 310 stainless steel.

[0093] The movable heating plate 3 is provided with a target material and a back plate whose welding surfaces are attached together, and the back plate is located under the target material and is in direct contact with the movable heating plate 3 .

[0094] The material of the target is copper, and the material of the back plate is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com