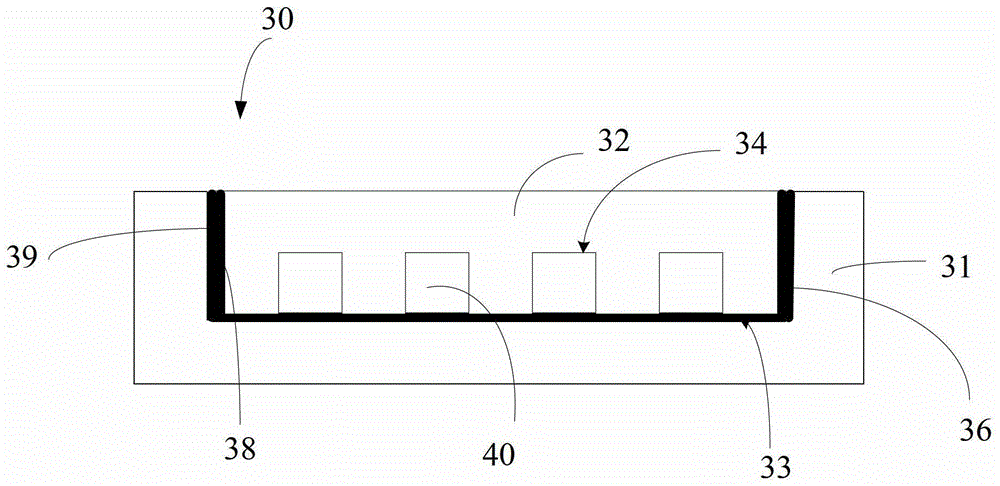

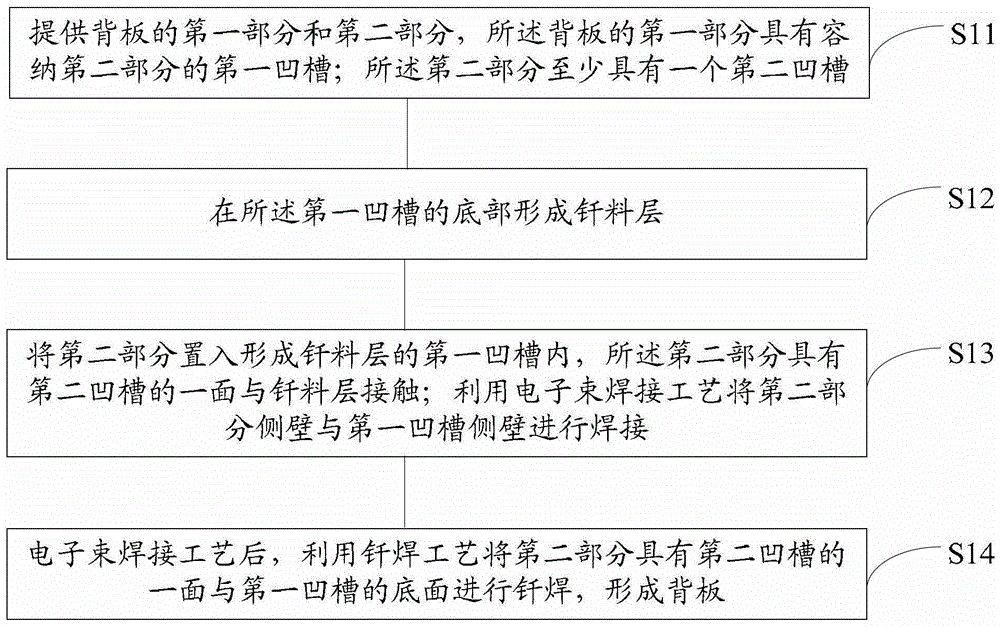

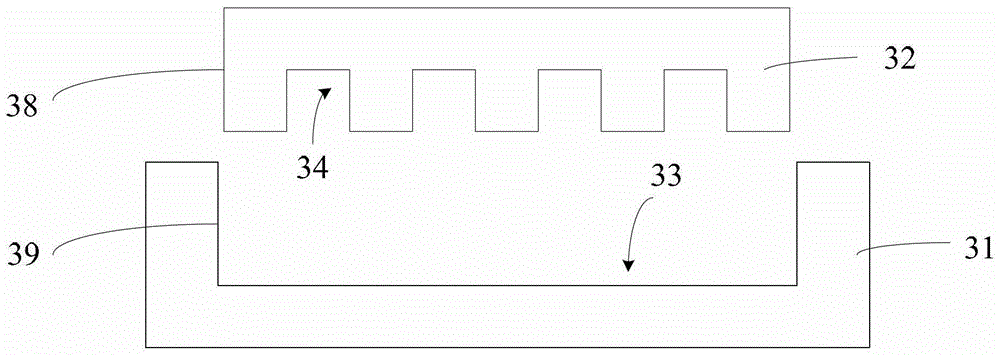

Manufacturing method of backplane and backplane

A manufacturing method and backplane technology, which are applied to manufacturing tools, ion implantation plating, welding equipment, etc., can solve the problems of low quality of substrate coating, unable to meet the requirements of sputtering process, short service life of backplane, etc. Realize the effect of large area welding, small welding seam and high welding bonding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The inventors found and analyzed that the service life of the backplane in the prior art is short, and the quality of the substrate coating is not high, and the reason why it cannot meet the increasingly demanding sputtering process is:

[0049] The impact of high-pressure cooling water on the back plate of the target assembly can effectively accelerate the heat dissipation of the target. -9 Under the high vacuum of Pa, and the back of the back plate is impacted by cooling water for a long time, a huge pressure difference is formed on the upper and lower sides of the target assembly, which makes a depression on the back of the back plate. The use of the back plate The service life is short, and the depression of the back plate will also cause the front of the corresponding target to protrude upwards, therefore, it will also affect the service life of the target assembly. What's more, due to the protrusion on the front of the target, it will directly cause The deviation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com