Forming method of backplane and backplane

A backplane and bottom plate technology, applied in metal processing, circuits, semiconductor devices, etc., can solve the problems of cover plate deformation, cost a lot of manpower and time, and assembly difficulty coefficient, so as to reduce assembly difficulty, improve assembly accuracy, and improve The effect of welding bond rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

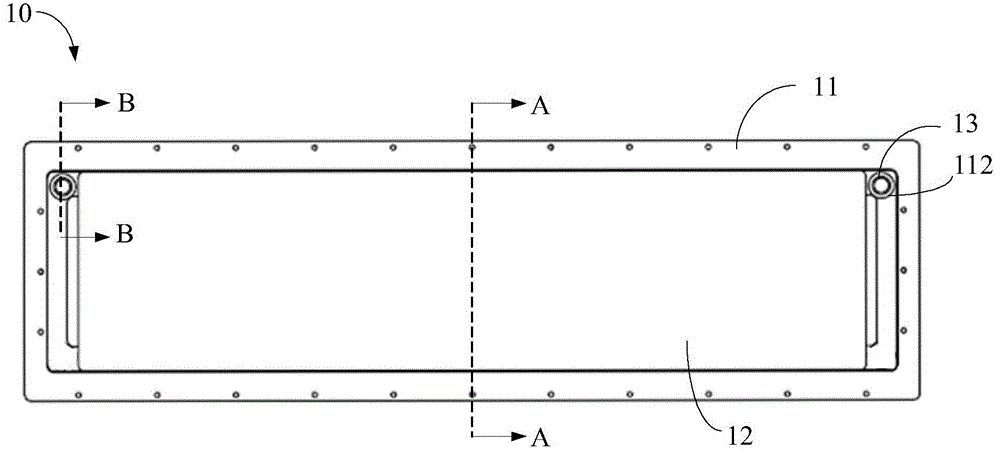

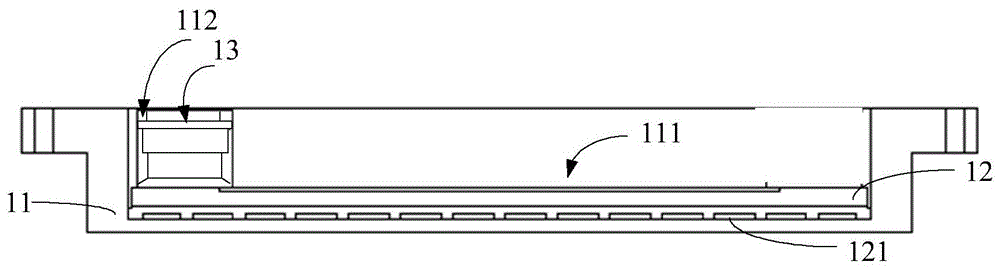

[0046] After research, in the prior art, the assembly difficulty coefficient of the cover plate, the solder, and the bottom plate is high, and the welding bonding rate of the formed back plate is low. In addition, there will be solder in the gap between the side wall of the target installation groove of the bottom plate and the side wall of the cover plate. The solder in this gap will seriously affect the appearance of the back plate, and it will take a lot of manpower and time to fix the gap. In the process of removing the solder at the gap, the reason why the cover plate is easy to deform is as follows:

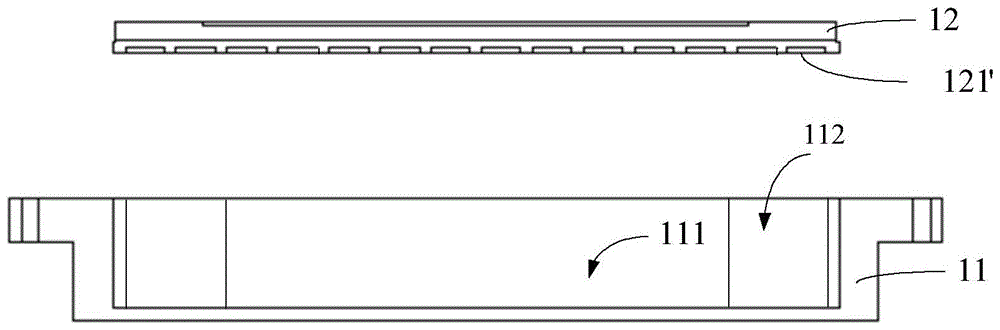

[0047] In the prior art, the brazing filler metal has a flake structure. Put the brazing material on the bottom front of the target mounting groove 111, and firstly put the brazing material in contact with the side of the cover plate 12 that has the cooling water channel groove structure 121', specifically, the brazing material and the cooling water channel groove structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com