A welding method of wti target material and copper back plate

A welding method and technology for copper backplanes, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems of WTi prone to cracks, short service life, unsatisfactory sputtering effect, etc., to avoid Discharge phenomenon, improve welding bonding rate, reduce the effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

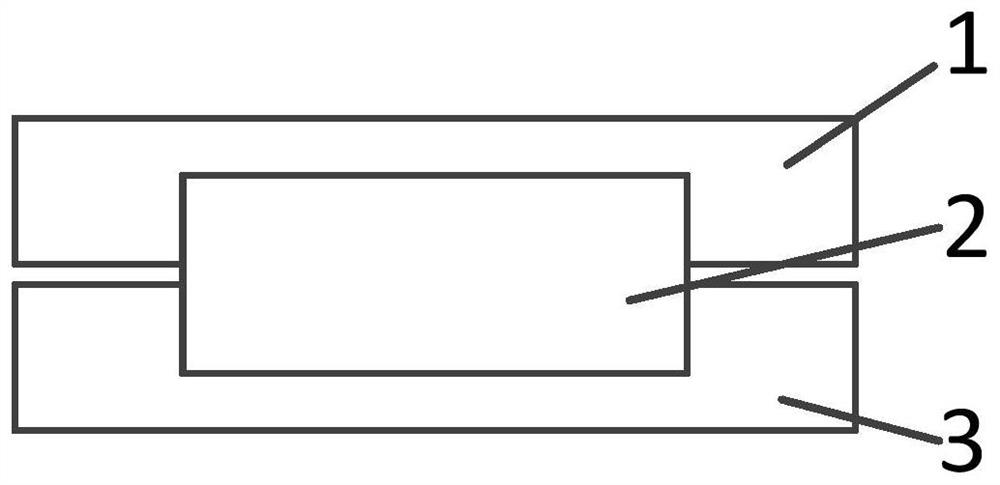

[0043] This embodiment provides a welding method for a WTi target and a copper back plate. The welding method includes: assembling the WTi target 2, the copper back plate 3 and the cover plate 1, and then putting them into the sheath and removing them sequentially. Gas treatment and welding;

[0044] Wherein, the welding surface of the WTi target 2 is provided with an inverted triangular groove; the welding surface of the copper back plate 3 is sequentially subjected to acid treatment and alkali treatment; 2 is a centrally symmetrical assembly, such as figure 1 shown; the maximum width of the groove is 4mm; the vertical depth of the groove is 1.7mm; the pitch of the groove is 7mm; the acid treatment is to use acid solution to process the copper back plate welding surface; the acid The solution is concentrated hydrochloric acid; the time of the acid treatment is 30min; the alkali treatment is to use an alkali solution to process the welding surface of the copper backboard; the...

Embodiment 2

[0047] This embodiment provides a welding method for a WTi target material and a copper back plate, the welding method includes: assembling the WTi target material, copper back plate and cover plate, and then putting them into a sheath for degassing treatment and welding;

[0048] Wherein, the welding surface of the WTi target is provided with a groove; the welding surface of the copper back plate is sequentially subjected to acid treatment and alkali treatment; the assembly is a symmetrical assembly of the copper back plate and the cover plate centered on the WTi target; The maximum width of the groove is 3mm; the vertical depth of the groove is 2mm; the distance between the grooves is 6mm; the acid treatment is to use an acid solution to process the welding surface of the copper backboard; the acid solution is concentrated nitric acid; The time of the acid treatment is 40min; the alkali treatment is to use an alkali solution to process the welding surface of the copper backb...

Embodiment 3

[0051] This embodiment provides a welding method for a WTi target material and a copper back plate, the welding method includes: assembling the WTi target material, copper back plate and cover plate, and then putting them into a sheath for degassing treatment and welding;

[0052] Wherein, the welding surface of the WTi target is provided with a groove; the welding surface of the copper back plate is sequentially subjected to acid treatment and alkali treatment; the assembly is a symmetrical assembly of the copper back plate and the cover plate centered on the WTi target; The maximum width of the groove is 5mm; the vertical depth of the groove is 1.2mm; the distance between the grooves is 8mm; the acid treatment is to use an acid solution to process the welding surface of the copper backboard; the acid solution is concentrated hydrochloric acid The time of the acid treatment is 20min; the alkali treatment is to use an alkali solution to process the welding surface of the coppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com