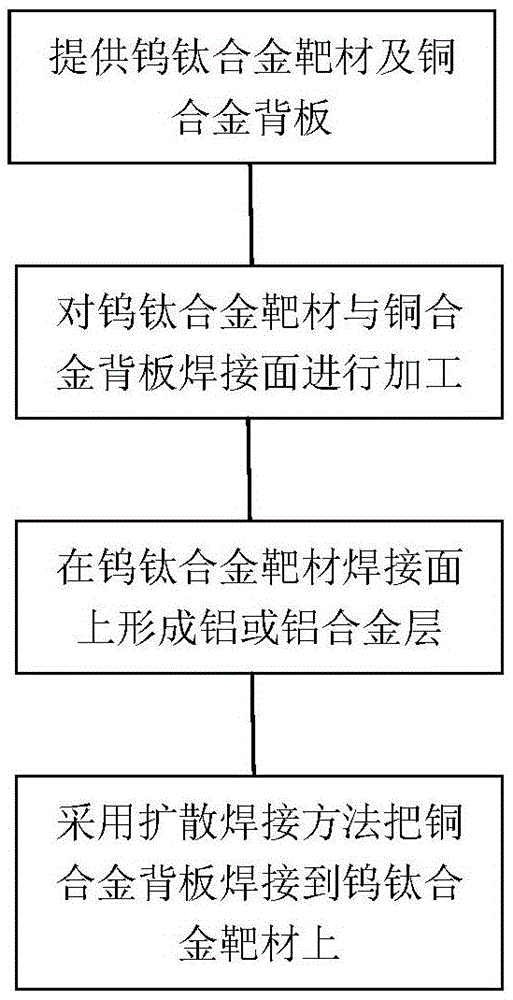

A kind of tungsten-titanium alloy target material welding method

A technology of tungsten-titanium alloy and welding method, which is applied in welding equipment, welding/welding/cutting articles, metal processing, etc., can solve the problems of target component connection failure, sputtering process inability, solder melting, etc., to increase effective Large area, good plasticity, and the effect of improving welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A tungsten-titanium alloy target with a diameter of 300 mm is welded to a copper alloy back plate with a diameter of 310 mm, wherein the composition of the tungsten-titanium alloy is W-10% Ti, and the composition of the copper alloy back plate is Cu-0.7% Cr.

[0036] First, the welding surface of the tungsten-titanium target is sandblasted, with a roughness of 4.3 μm, which is uniform. The welding surface of the copper alloy backplane is CNC lathe machined with V-shaped grooves, with a depth of 0.4mm and a groove spacing of 0.5mm.

[0037] The middle layer is made of grade 1050 industrial pure aluminum with a thickness of 2mm.

[0038] Put the processed copper alloy back plate, 1050 aluminum sheet, and tungsten-titanium target into the 6061 aluminum alloy sheath in turn, and place them in the 8×10 -3 Electron beam sealing welding in Pa vacuum.

[0039] The package that has been sealed and welded is welded in a hot isostatic pressing furnace at a temperature of 500°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com