Welding method of copper target blank and copper alloy backing plate

A welding method and copper alloy technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of easy oxidation and affect the welding effect of target components, so as to prevent oxidation and prevent the target from detaching from the back plate. , the effect of high bonding tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

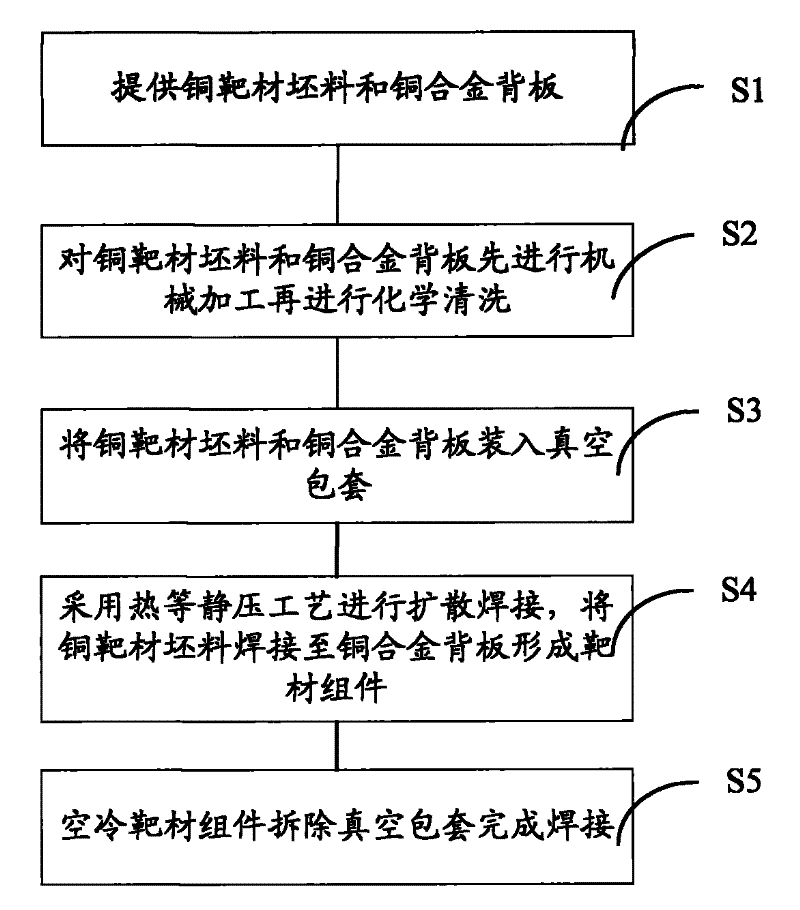

Method used

Image

Examples

Embodiment 1

[0037] The following are the process steps and welding results of diffusion welding between 99.995% high-purity Cu target blank and Cu alloy backplane:

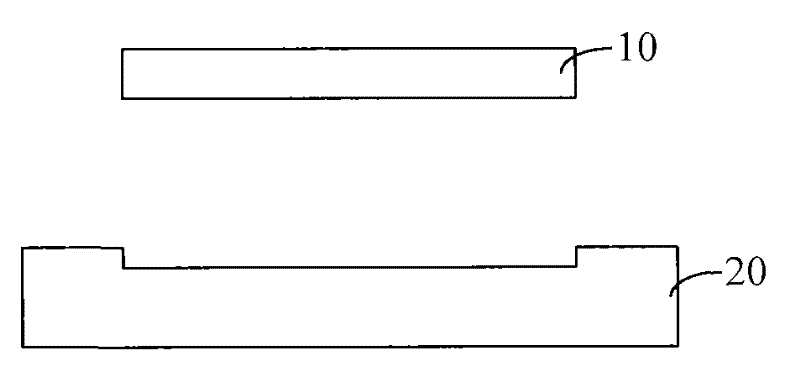

[0038] (1) Surface processing of the target blank and the back plate: machine the surface of the Cu target blank and the surface of the Cu alloy back plate to make them bright, especially to make the surface finish of the two contact surfaces reach 0.2um.

[0039] (2) Chemical cleaning of the target blank and the back plate: the surface of the Cu target blank and the Cu alloy back plate is cleaned with hydrochloric acid to remove soluble impurities on the surface. The volume ratio of hydrogen chloride to water in hydrochloric acid is 1:5.

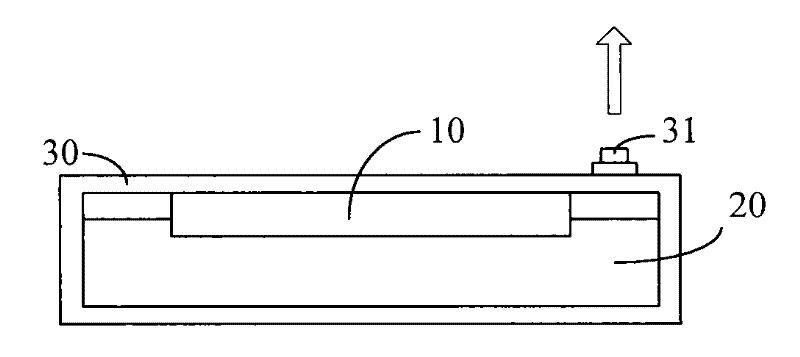

[0040] (3) Put the target blank and back plate into the vacuum bag:

[0041] First put the Cu target material blank and the Cu alloy back plate into the thin-walled vacuum sheath welded and formed, the vacuum sheath is 1.0mm ~ 2.0mm low carbon steel or copper alloy welded and formed, and ...

Embodiment 2

[0048] The following are the process steps and welding results of diffusion welding between 99.99% high-purity Cu target blank and Cu alloy backplane:

[0049] (1) Surface processing of the target blank and the back plate: Machining the surface of the Cu target blank and the surface of the Cu alloy back plate to make them bright, especially to make the surface finish of the two contact surfaces reach 3.2um.

[0050] (2) Chemical cleaning of the target blank and the back plate: the surface of the Cu target blank and the Cu alloy back plate is cleaned with hydrochloric acid to remove soluble impurities on the surface. The volume ratio of hydrogen chloride to water in hydrochloric acid is 1:5.

[0051] (3) Put the target blank and back plate into the vacuum bag:

[0052] First put the Cu target blank and the Cu alloy back plate into a thin-walled vacuum sheath welded and formed, the vacuum sheath is 1.0mm ~ 2.0mm low carbon steel or copper alloy welded and formed, and then vacuu...

Embodiment 3

[0059] The following are the process steps and welding results of diffusion welding between 99.99% high-purity Cu target blank and CU alloy backplane:

[0060] (1) Surface processing of the target blank and the back plate: machine the surface of the Cu target blank and the surface of the CU alloy back plate to make them bright, especially to make the surface finish of the two contact surfaces reach 1.6um.

[0061] (2) Chemical cleaning of target blanks and back plates: use hydrochloric acid to clean the surface of Cu target blanks and CU alloy back plates to remove soluble impurities on the surfaces. The volume ratio of hydrogen chloride to water in hydrochloric acid is 1:5.

[0062] (3) Put the target blank and back plate into the vacuum bag:

[0063] First put the Cu target blank and the CU alloy back plate into a thin-walled vacuum sheath welded and formed, the vacuum sheath is 1.0mm ~ 2.0mm low carbon steel or copper alloy welded and formed, and then vacuumize to 10 -3 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com