Movable combination pin

A movable and pin technology, applied in the direction of connecting components, bolts, mechanical equipment, etc., can solve the problems of inconvenient disassembly and assembly, difficult to restore the original state, and large consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

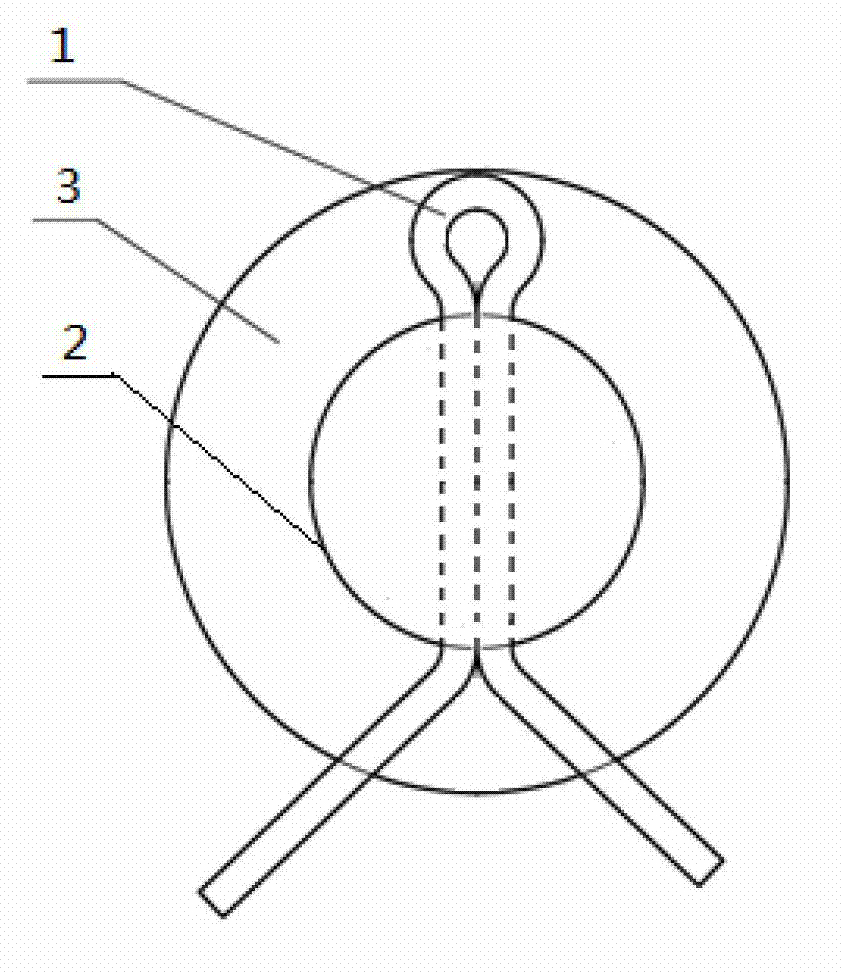

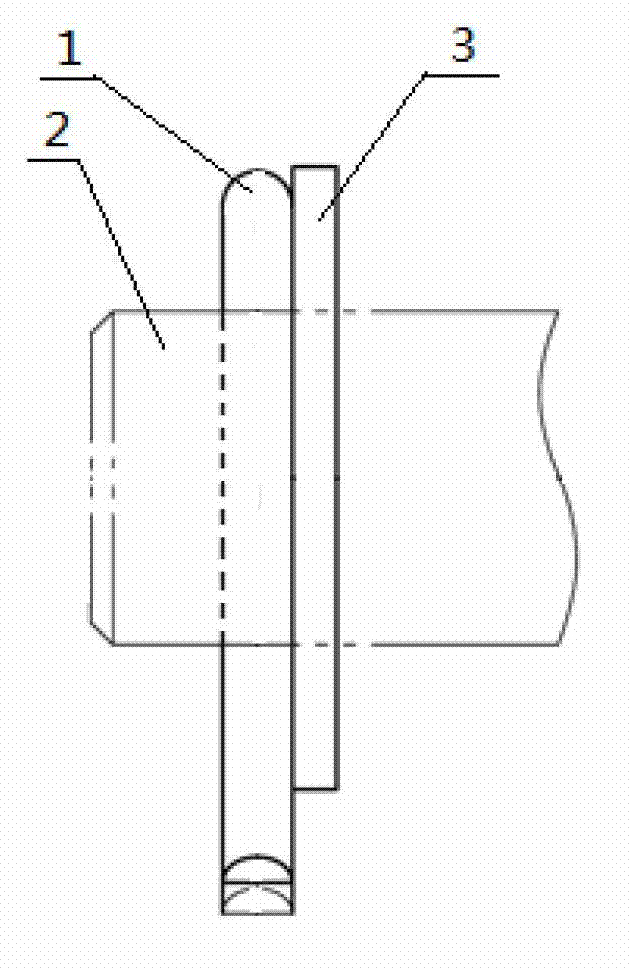

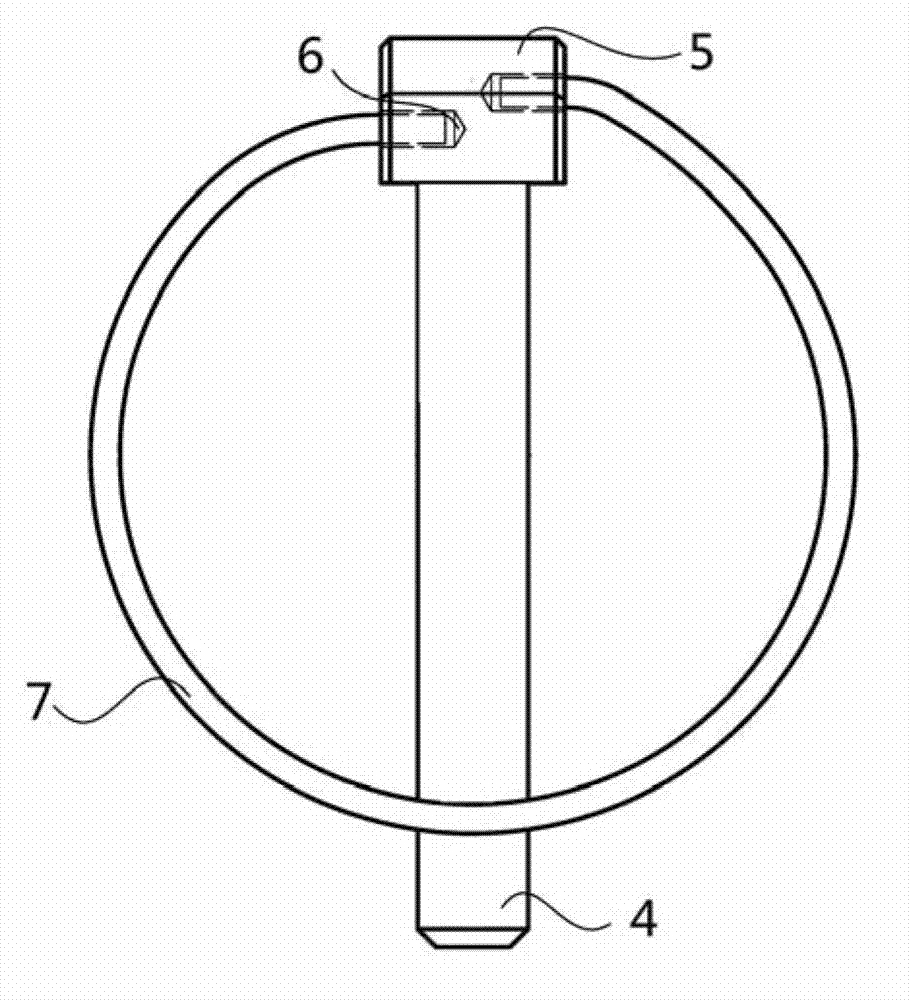

[0019] image 3 It is a schematic structural diagram of a movable combination pin provided in this embodiment, Figure 4 The schematic diagram of the use state of the active combination pin provided for this embodiment, combined with image 3 and Figure 4 As shown, the movable combination pin provided in this embodiment includes a cylindrical pin shaft 4, and one end of the pin shaft 4 is provided with a boss 5, and the boss 5 has two holes 6, and the two holes 6 are respectively located on opposite sides of the boss 5. Both sides, and the axes of the two holes 6 are not on the same straight line; the movable combination pin also includes an elastic ring 7, the elastic ring 7 is annular with an opening, and its two ends are inserted into the two holes 6 respectively. The diameter of the pin shaft 4 in the movable combination pin is preferably the diameter of a standard cotter pin. The shape of the pin shaft 4 matches the pin hole shape, if the pin hole shape is a circular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com