Double-layer car pallet

A technology for pallets and cars, applied in the field of double-layer car pallet devices, can solve the problems of long loading and boxing, unfavorable anti-corrosion treatment, shortening the service life of the frame, etc., and achieves uniform apparent quality and convenient production organization. , The effect of saving logistics costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

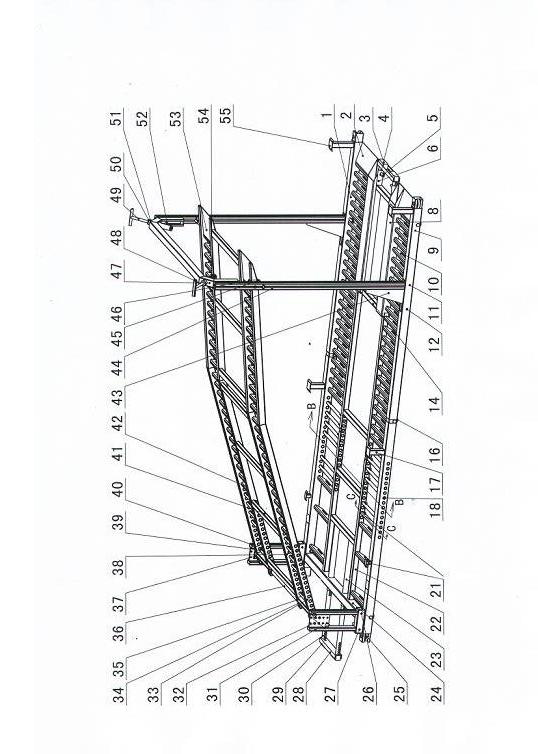

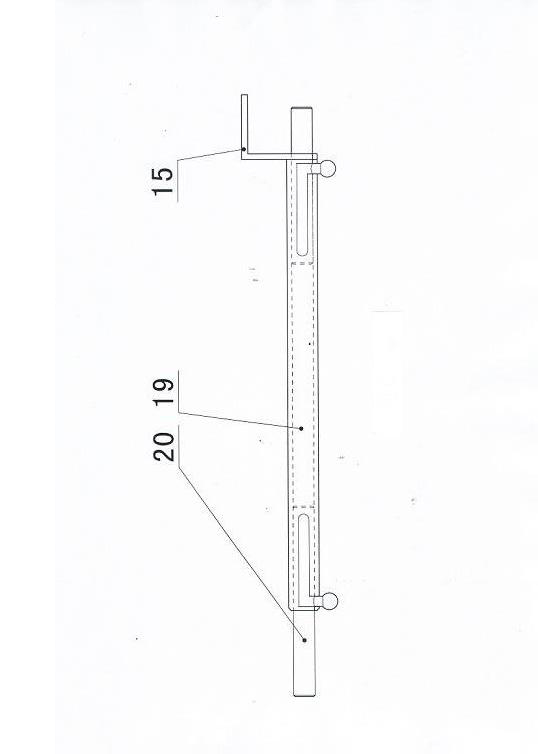

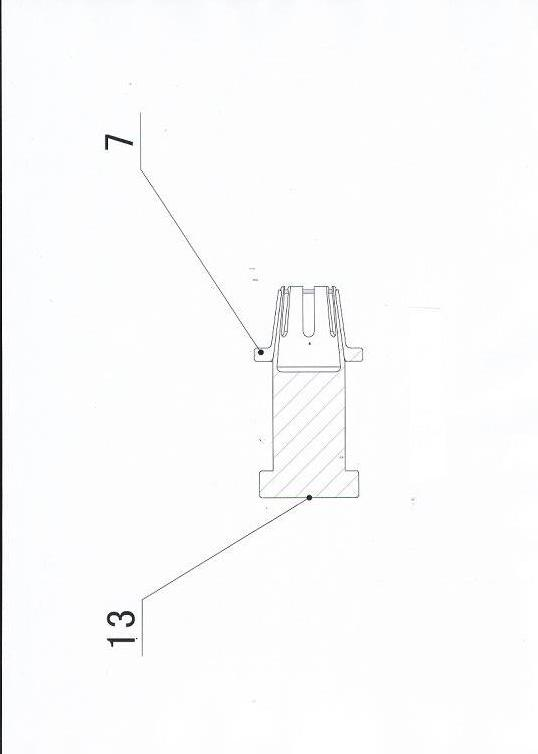

[0035] The invention discloses a structure and a manufacturing method of a double-deck car pallet. The double-deck car pallet is composed of a bottom pallet assembly, a small frame assembly, a large frame assembly, an upper pallet assembly, a front box lifter, a rear front box lifter and a support Apex composition.

[0036] The composition method of the double-deck car pallet is: the small frame assembly uses the small frame bolts, the small frame riveting pins are hinged with the symmetrically distributed and fixed seats on both sides of the bottom tray assembly, and the large frame assembly is also connected to the bottom tray assembly in the same way. The tray is hinged; the left side of the upper tray assembly is fixedly connected to the small frame assembly through the flanges on both sides of the large shaft on it. As a preference, the connection method here is completed with the elastic buckle pin assembly 32, which replaces the threaded connection ;The remaining part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com