Polypropylene plastic water pipe for shower room backboard

A technology of polypropylene plastic and polypropylene, which is applied in the direction of pipeline connection layout, pipes/pipe joints/fittings, mechanical equipment, etc., which can solve the problems of easy aging, cracking, easy damage, water leakage, and many interfaces, so as to achieve small heat loss, Not easy to leak, neat and beautiful installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

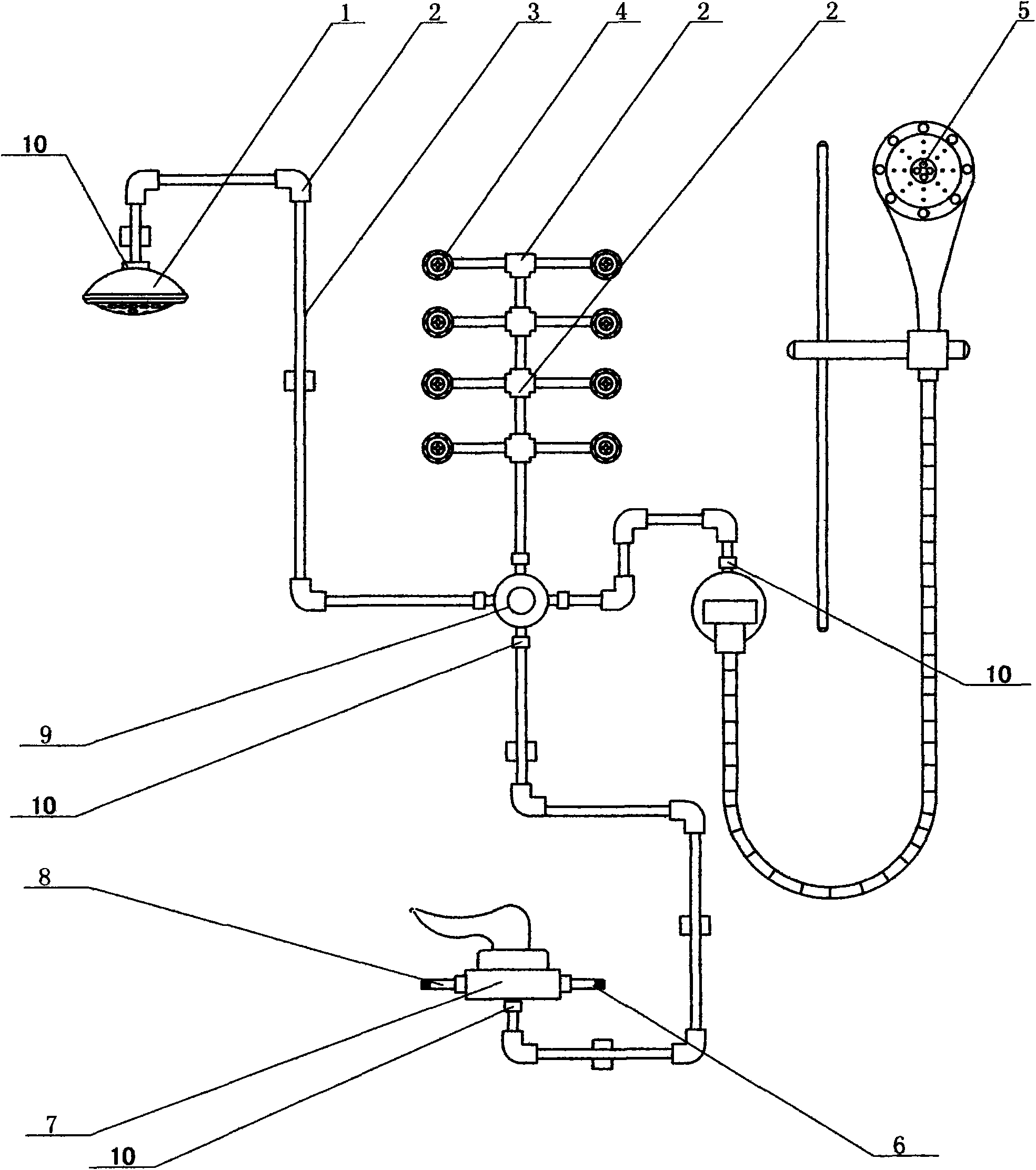

[0034] figure 1 Shown is a schematic diagram of the distribution of polypropylene plastic water pipes on the back of the shower room. Top spray 1, nozzle 4, movable shower 5. The water pipe 3 that the present invention adopts is the polypropylene plastic water pipe, is installed in the back side of shower room, invisible when using shower room to shower.

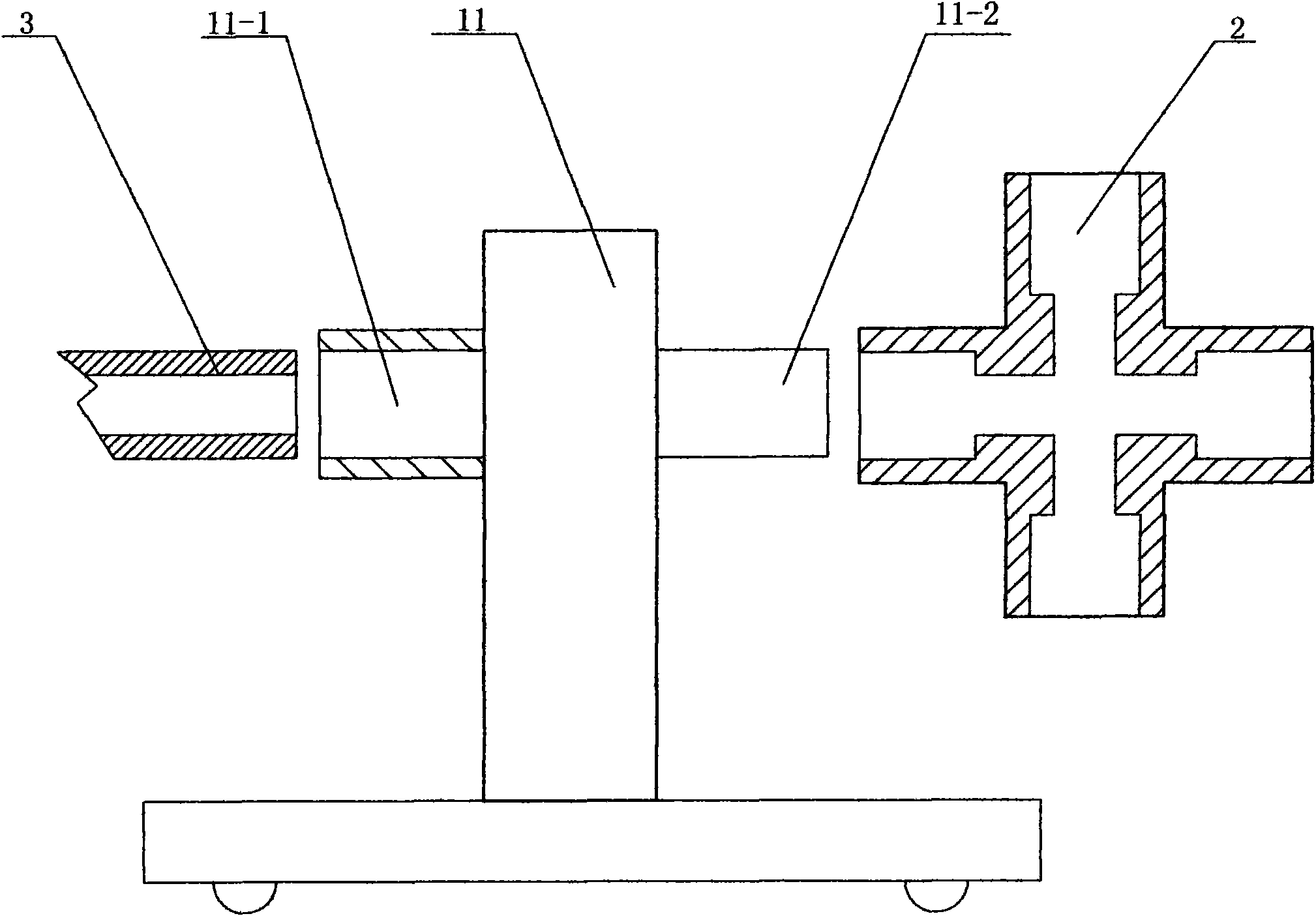

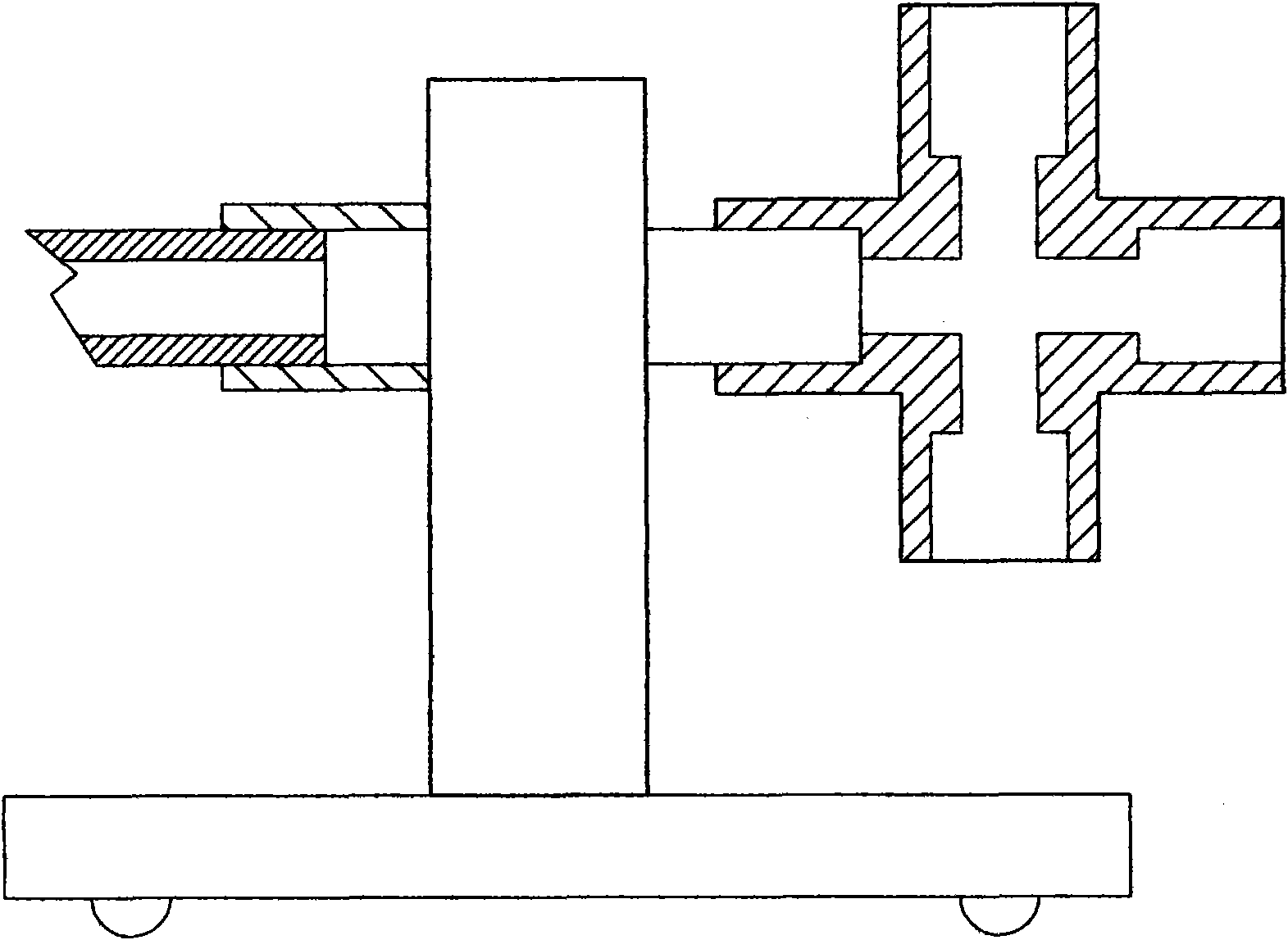

[0035] figure 2 , image 3 , Figure 4 with Figure 5 It is shown that the water pipe 3 and the joint are processed and connected by a heat fusion machine 11. The heat fusion machine 11 is respectively provided with a water pipe heat fusion head 11-1 and a joint heat fusion head 11-2, and one end of the water pipe 3 is connected to a polypropylene plastic joint. One end of 2 is heated on the water pipe hot-melt head 11 and the joint hot-melt head 12 respectively. It only takes a few seconds for the surface of the water pipe 3 and the polypropylene plastic joint 2 to melt. At this time, the water pipe 3 is quickly inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com