Anisotropic dielectric elastomer fiber driver and preparation method thereof

A dielectric elastomer, anisotropic technology, applied in the field of automation, can solve the problems of single deformation mode, single degree of freedom, unfavorable practical application, etc., and achieve the effect of large driving deformation, good compatibility and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

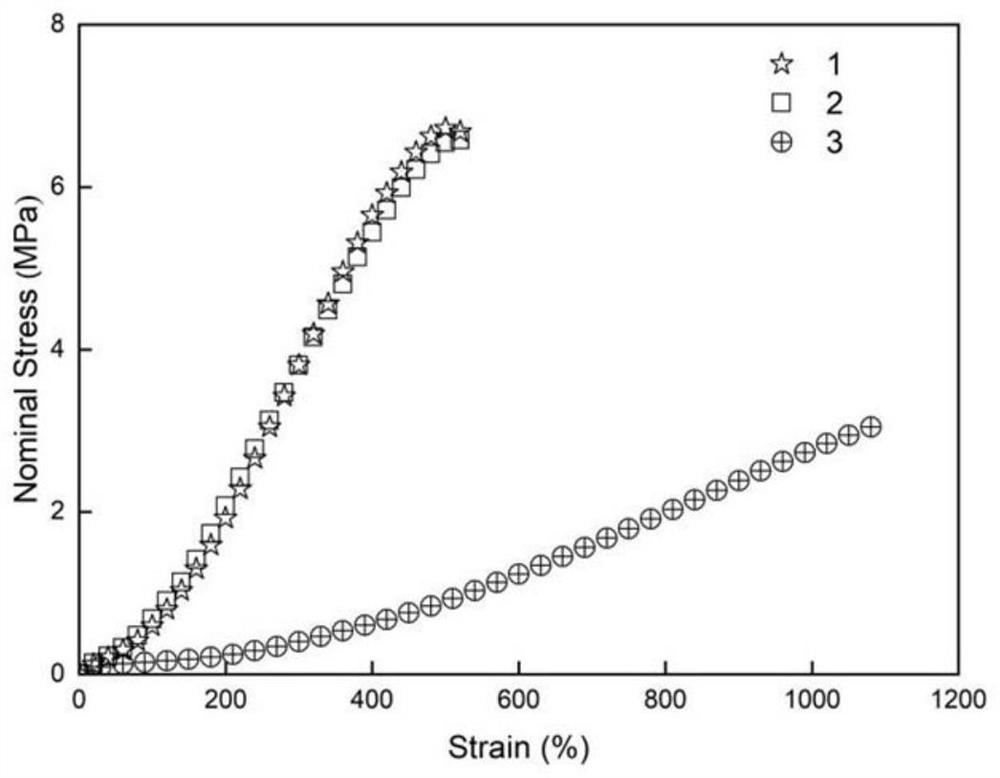

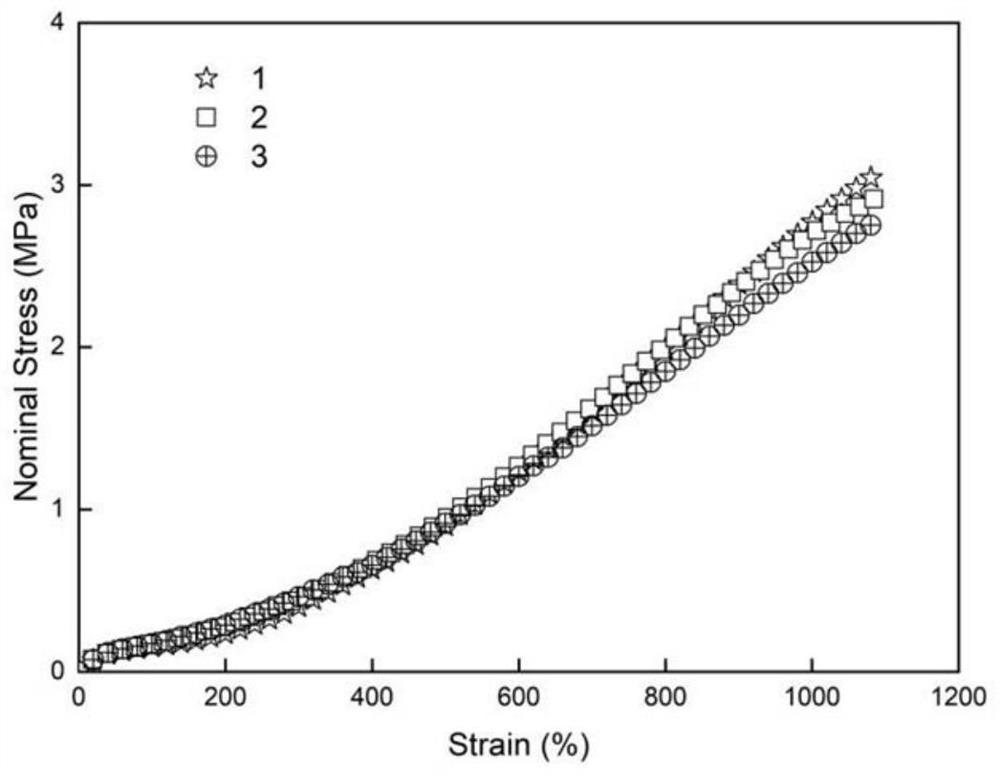

[0043] Example 1: Preparation and properties of polystyrene-b-poly(n-butyl acrylate)-b-polystyrene triblock copolymer (SBAS) dielectric elastomer anisotropic film

[0044] The first step: completely dissolve 1 mass part of SBAS triblock copolymer (molecular weight: 1.5W-12W-1.5W) in 5 mass parts of THF;

[0045] Step 2: Place the scraper on the non-stick polyester film substrate, and apply the above THF solution between the scraper and the substrate, and the scraper drives the solution to move relative to the substrate at a speed of 1mm / s, so that a layer is evenly deposited on the substrate Wet film, placed for 1 hour to evaporate the solvent, then form a dry film, then continue to dry for 12 hours under vacuum at 120°C to obtain the initial film of SBAS triblock copolymer dielectric elastomer;

[0046] The third step: uniaxially stretch the initial film of the above-mentioned SBAS triblock copolymer dielectric elastomer, take a film with a length of 1, fix one end, stretch t...

Embodiment 2

[0050] The first step: completely dissolve 1 mass part of SBAS triblock copolymer (molecular weight: 1.5W-12W-1.5W) in 5 mass parts of THF;

[0051] Step 2: Place the scraper on the non-stick polyester film substrate, and apply the above THF solution between the scraper and the substrate, and the scraper drives the solution to move relative to the substrate at a speed of 2mm / s, so that a layer is evenly deposited on the substrate Wet film, placed for 2 hours to evaporate the solvent to form a dry film, and then dried under vacuum at 120°C for 12 hours to obtain the initial film of SBAS triblock copolymer dielectric elastomer;

[0052] The third step: uniaxially stretch the initial film of the above-mentioned SBAS triblock copolymer dielectric elastomer, take a film with a length of 1, fix one end, stretch the other end along the length direction until the film length is 4, and then The other end was fixed, and the stretched film was placed in an oven at 120°C for heat treatmen...

Embodiment 3

[0059] The first step: completely dissolve 2 mass parts of SBAS triblock copolymer (molecular weight: 1.5W-12W-1.5W) in 10 mass parts of tetrahydrofuran;

[0060] Step 2: Place the scraper on the non-stick polyester film substrate, and apply the above THF solution between the scraper and the substrate, and the scraper drives the solution to move relative to the substrate at a speed of 2mm / s, so that a layer is evenly deposited on the substrate Wet film, placed for 0.5h to evaporate the solvent to form a dry film, and then dried under vacuum at 120°C for 12h to obtain the initial film of SBAS triblock copolymer dielectric elastomer;

[0061] Step 3: Add 5 mg of carbon nanotubes and 0.9 g of sodium lauryl sulfate into 90 g of deionized water, ultrasonicate for 4 hours, then centrifuge at a speed of 5000 r / min for 10 min with a centrifuge, take the supernatant, and pump The carbon nanotube electrode was obtained by filtration.

[0062] Step 4: Cut the SBAS triblock copolymer die...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com