Light source

A technology of light source and generating source, applied in the field of light source, can solve the problems of high voltage application, high manufacturing cost, lack of practicability, etc., and achieve the effects of low voltage, improved linear propagation, and reduced crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

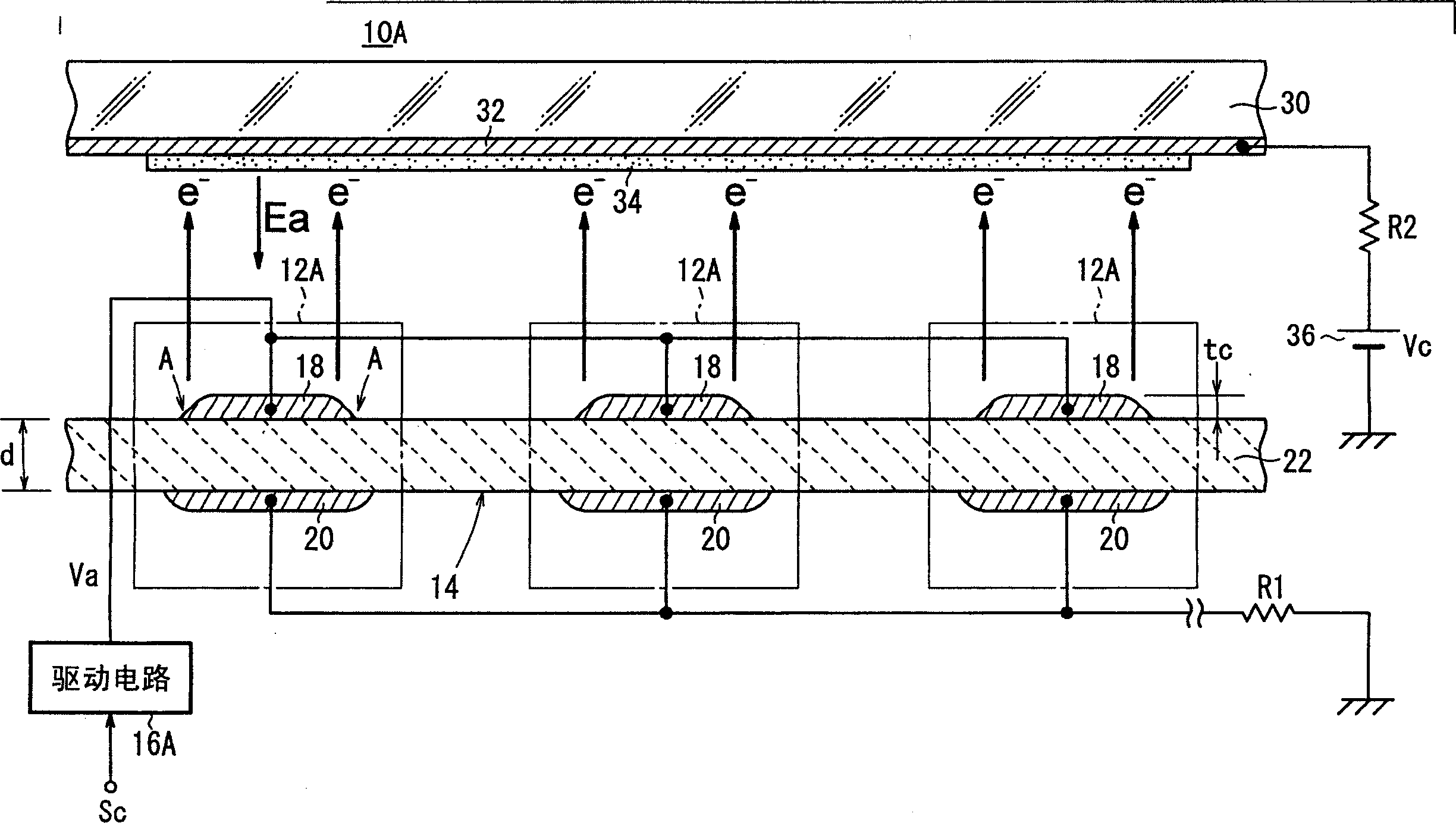

[0159] Refer to the following Figure 1 to Figure 77 Examples of the light source of the present invention will be described.

[0160] Such as figure 1 As shown, the light source 10A of the first embodiment has a light emitting section 14A in which a plurality of electron emitting elements 12A are arranged two-dimensionally, and a drive circuit 16A for applying a driving voltage va to each electron emitting element 12A of the light emitting section 14A.

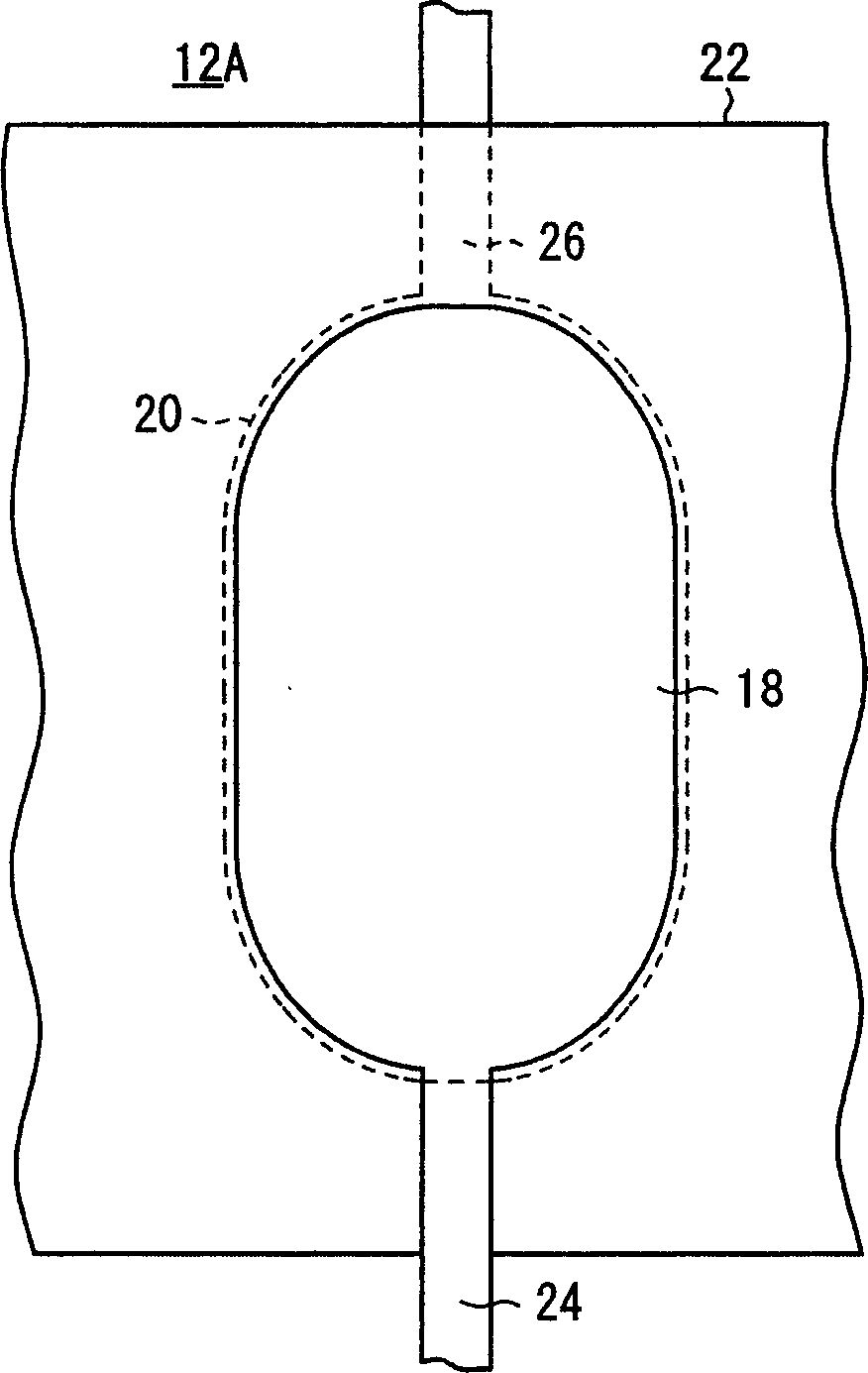

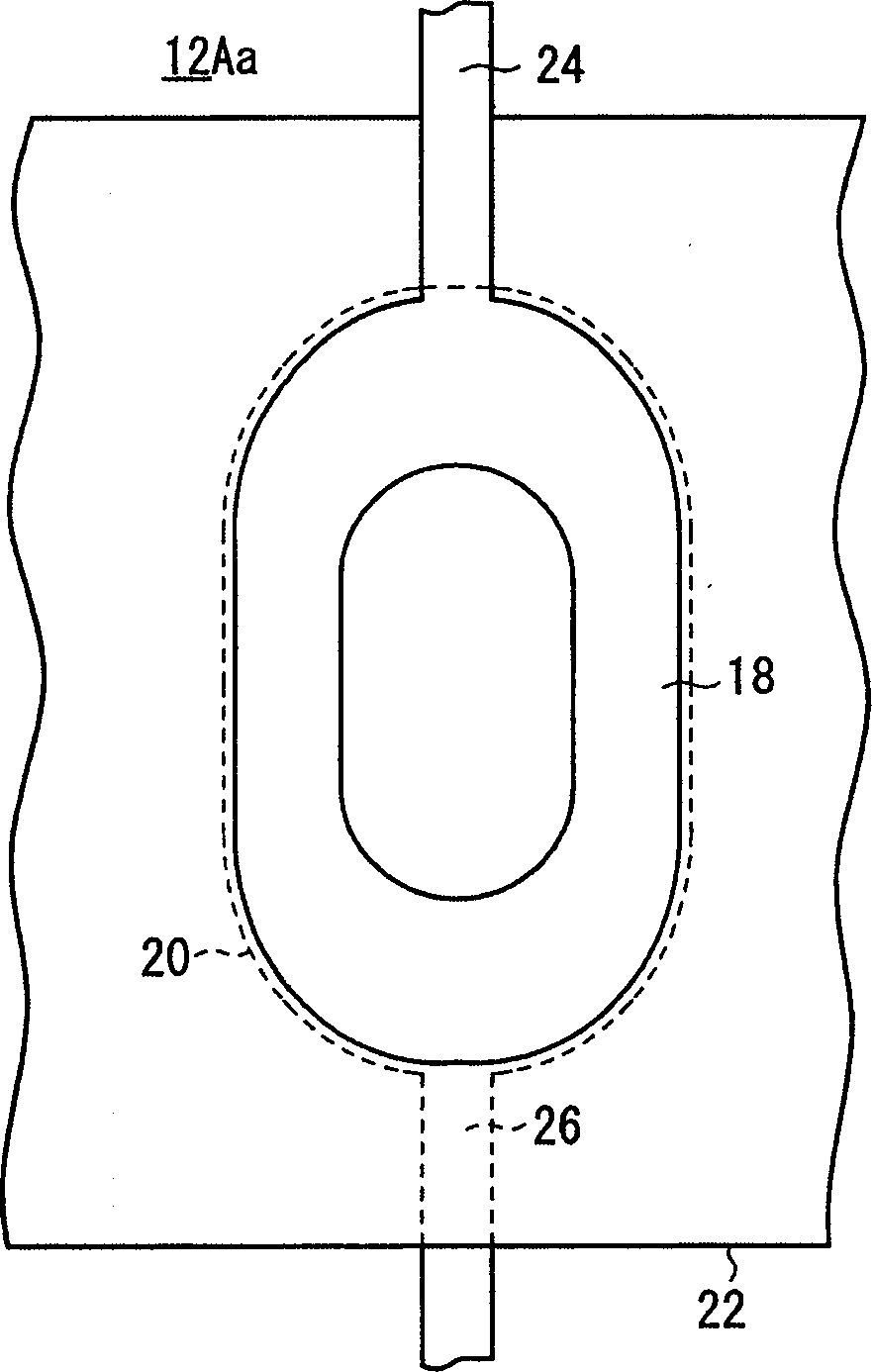

[0161] The driving circuit 16A applies a driving voltage Va to the first electrode (for example, the upper electrode) 18 and the second electrode of each electron emission element 12A according to a control signal Sc indicating turning on / off the light from the outside (a light-on / off switch, etc.). On the (lower electrode) 20, each electron emission element 12A is driven and controlled. A preferred example of the drive circuit 16A will be described later.

[0162] Such as figure 1 As shown, each electron emission element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com