Plasma display panel

A display panel and plasma technology, which is applied to AC plasma display panels, tube structural parts, discharge tubes, etc., can solve the problems of inability to reduce discharge voltage, deterioration of sputtering resistance, and deterioration of image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

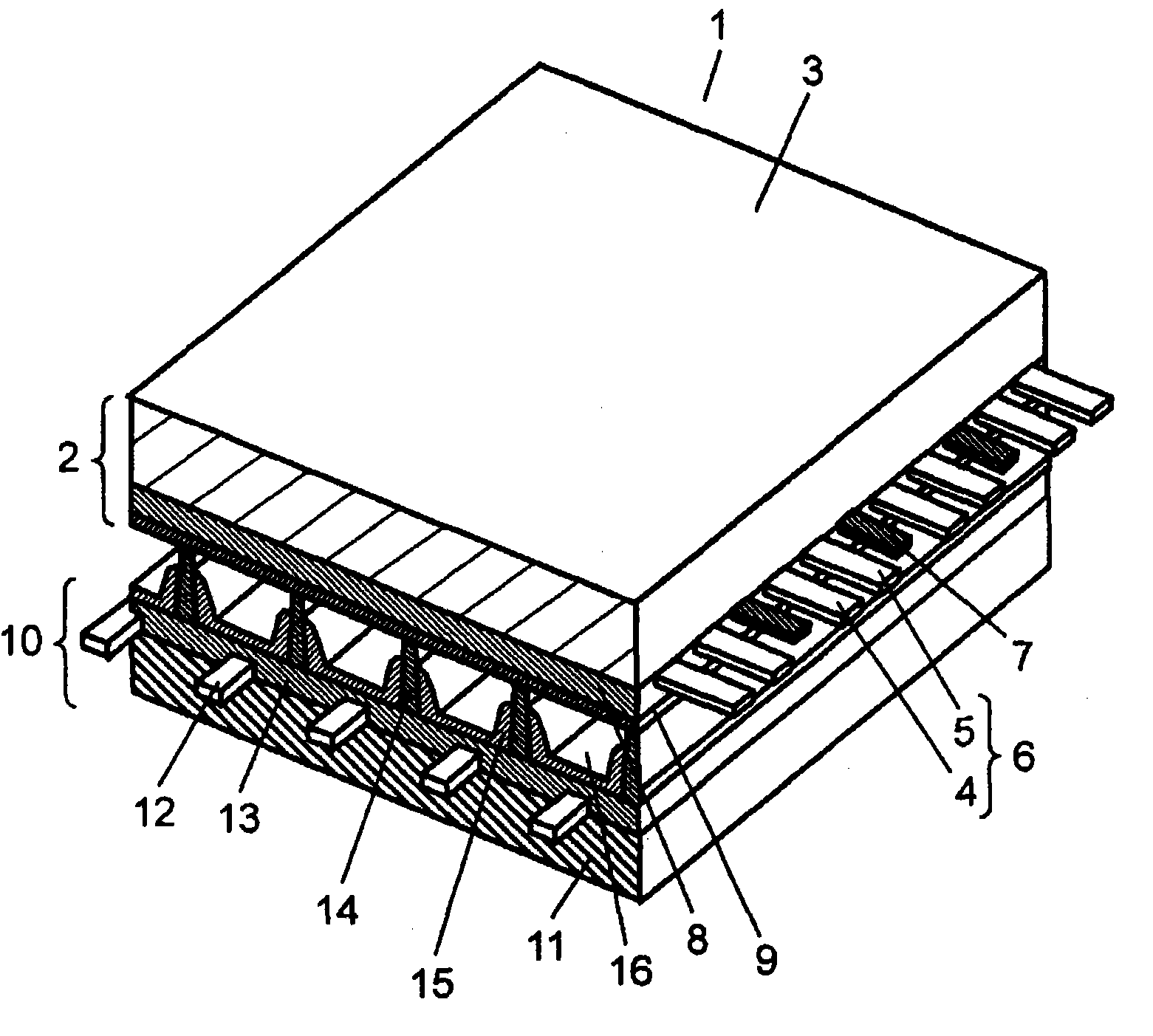

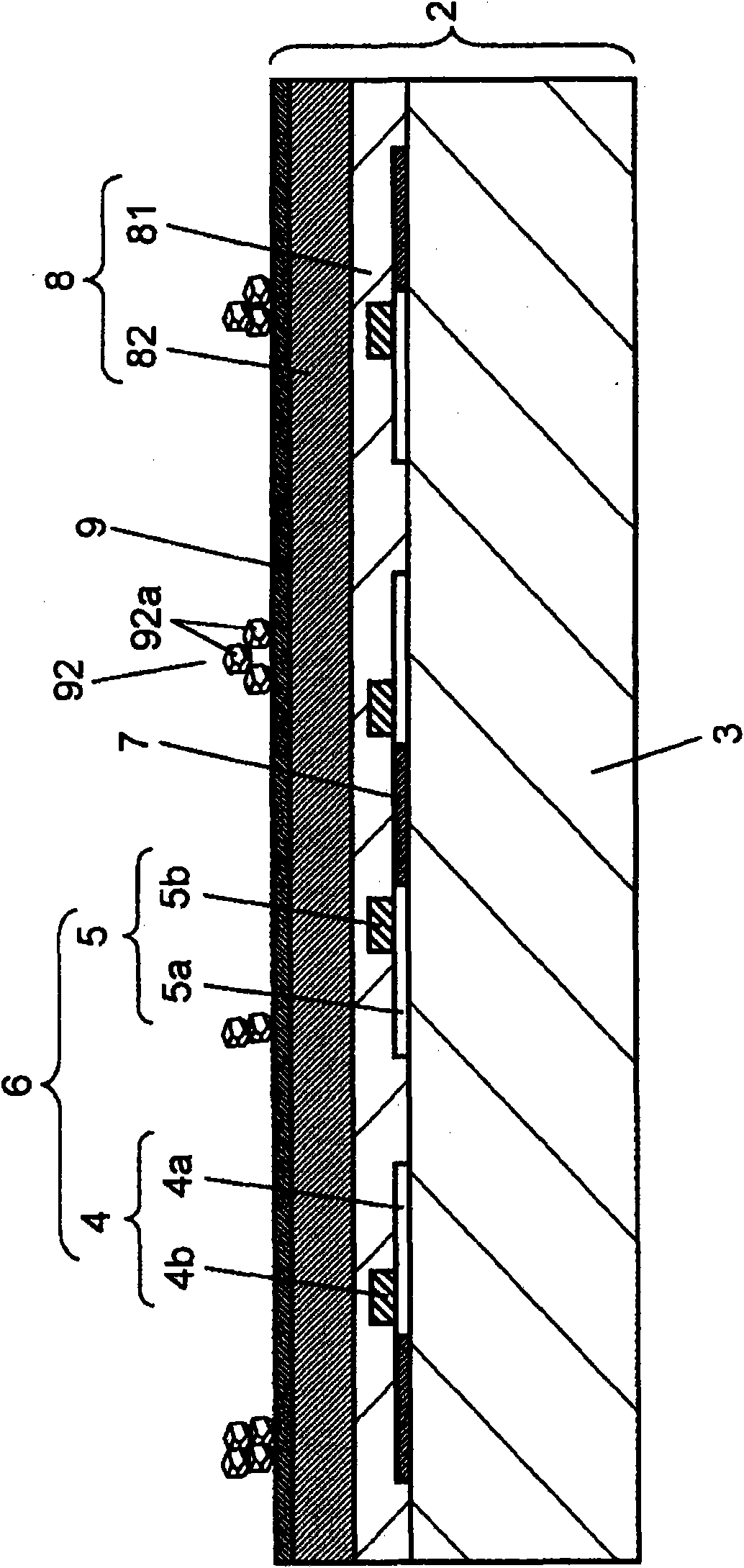

[0035] figure 1 It is a perspective view showing the structure of PDP1 in the embodiment of the present invention. The basic structure of the PDP 1 is the same as that of a normal AC surface discharge type PDP. Such as figure 1 As shown, for PDP1, the first substrate (hereinafter referred to as "front panel 2") composed of front glass substrate 3, etc., and the second substrate (hereinafter referred to as "rear panel 10") composed of rear glass substrate 11, etc. ”) are arranged facing each other, and the outer peripheral portion of the PDP 1 is hermetically sealed by a sealing member made of glass frit or the like. Discharge gas such as xenon (Xe) and neon (Ne) is sealed in discharge space 16 inside the sealed PDP 1 at a pressure of 400 Torr to 600 Torr (53300 Pa to 80000 Pa).

[0036] On the front glass substrate 3 of the front panel 2, a plurality of strip-shaped display electrodes 6 composed of scan electrodes 4 and sustain electrodes 5 and black stripes (light shieldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com