Plasma display panel and method for manufacturing same

A display panel and plasma technology, which is applied in the direction of AC plasma display panel, cold cathode manufacturing, electrode system manufacturing, etc., can solve difficult problems such as performance and characteristics, and achieve improved sputtering resistance, high-definition image quality, and reduced discharge The effect of lag time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

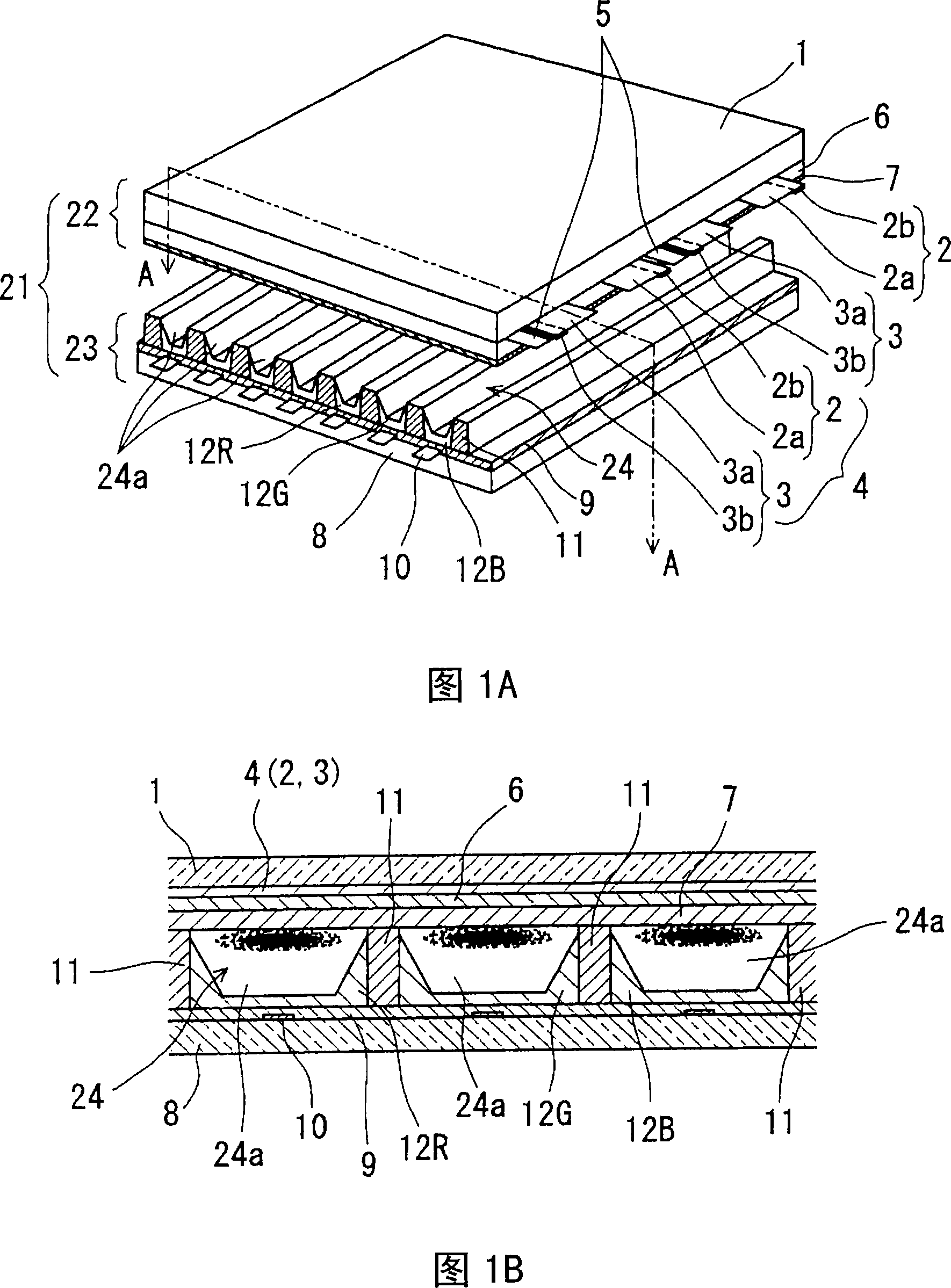

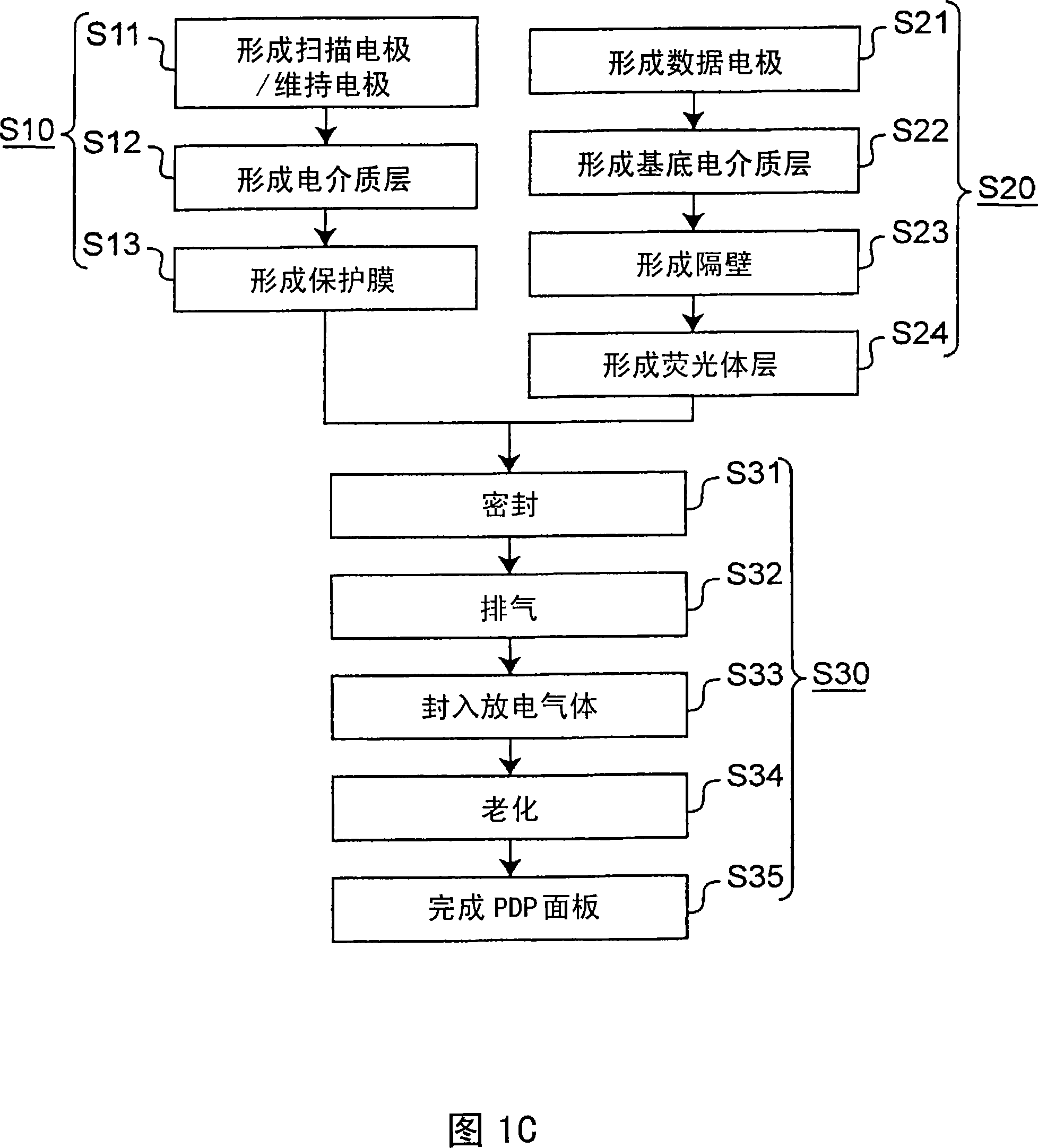

[0053] One embodiment of the present invention will be described with reference to FIGS. 1A to 8 .

[0054] 1A is an exploded perspective view showing an enlarged part of the structure of an AC-type PDP in the embodiment of the present invention, FIG. 1B is an enlarged cross-sectional view showing the AA portion of FIG. 1A, and FIG. A flow chart of the manufacturing process is schematically described in the AC-type PDP manufacturing method. 9A and 9B as background technology, the structure of a general AC-type PDP has been described. 8, the row electrodes and column electrodes are arranged orthogonally, and the discharge space 24 is formed by the intersection of the two electrodes constituting the row and column of the pixel (pixel) and the partition wall 11 between the two substrates 1 and 8, but based on the structure of FIG. 1A and FIG. 1B will be described again.

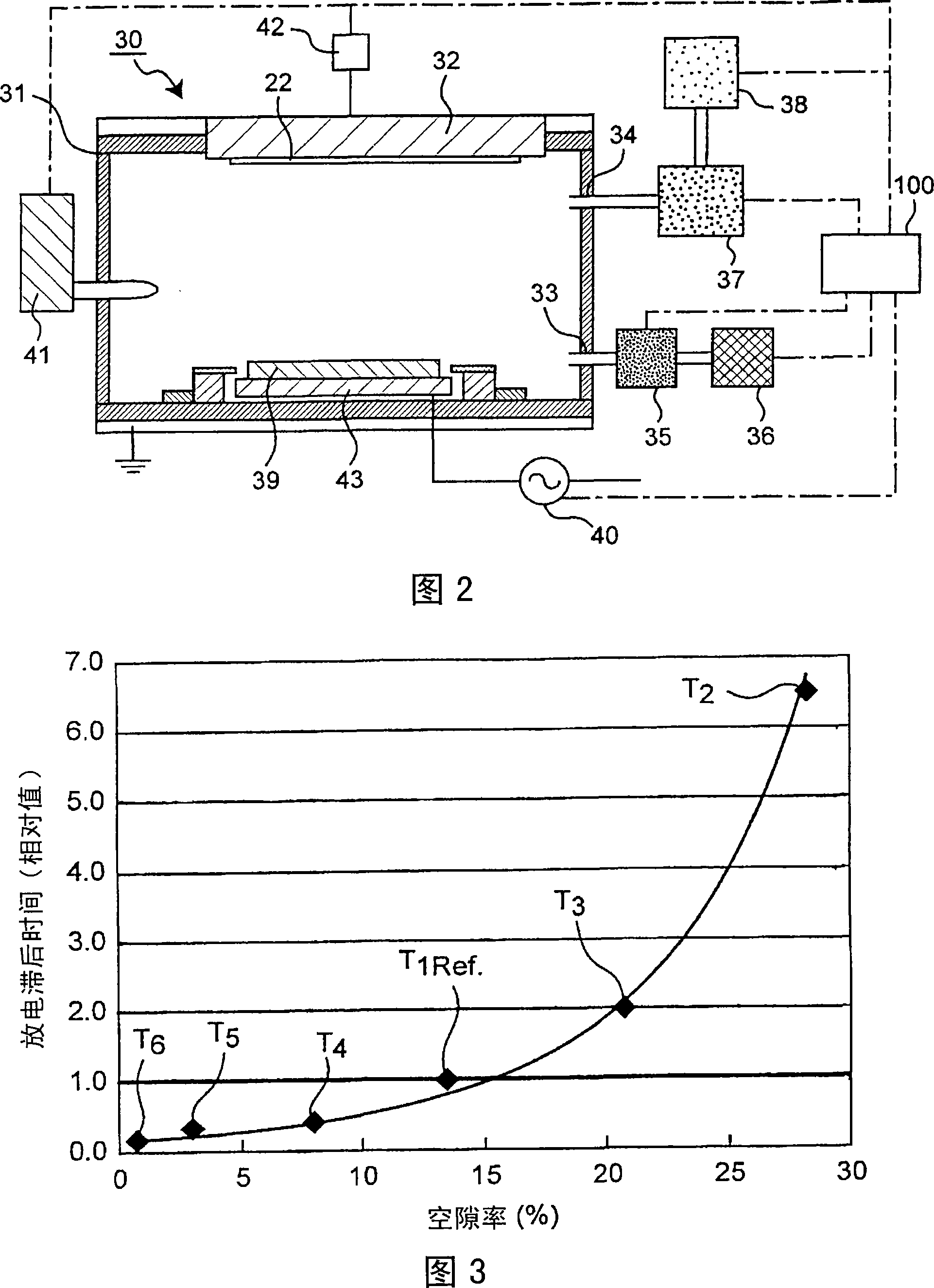

[0055] Next, FIG. 2 is a schematic configuration diagram of a film forming apparatus for forming the protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com