Electrode material

An electrode material and electrode technology, applied in the field of cold cathode fluorescent lamps, can solve the problems of accelerating electrode consumption of amalgam, reducing the life of fluorescent lamps, and making it difficult to prolong life, and achieve the effects of prolonging life, small current, and easy discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

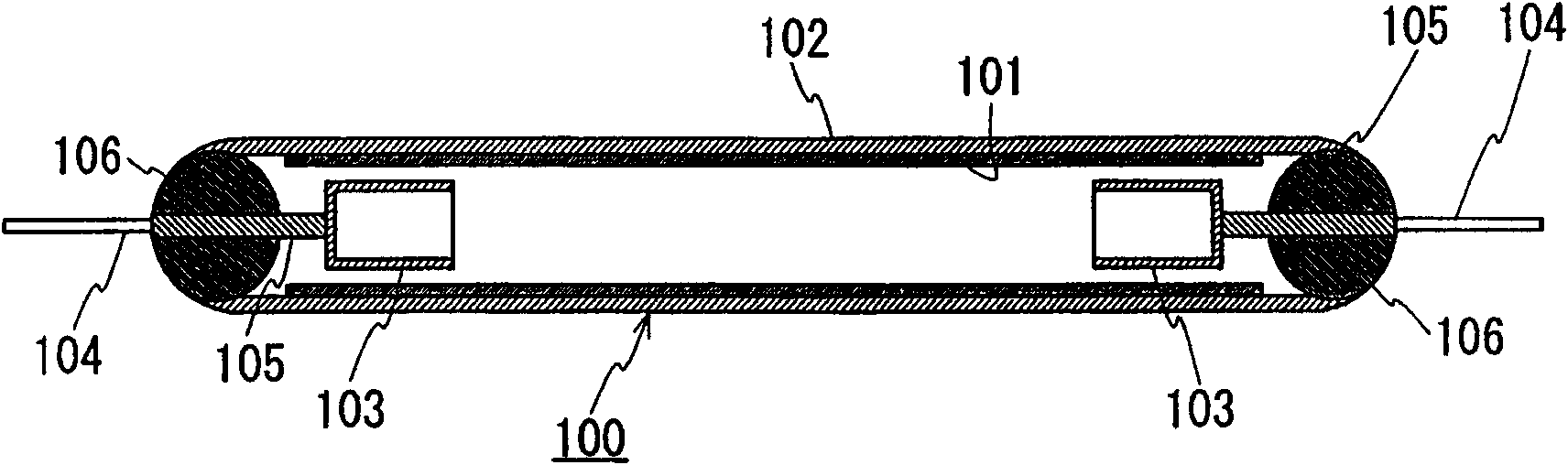

[0041] Embodiments of the present invention will be described below. Electrodes for cold cathode fluorescent lamps were prepared using Ni alloys having the composition (metal Nos. 1 to 36) shown in Tables 1 and 2. The electrodes are made of two electrode materials with different shapes. Specifically, a linear electrode material and a plate-shaped electrode material are prepared. A cup-shaped electrode is produced by forging a wire-shaped electrode material, and a cup-shaped electrode is produced by pressing a plate-shaped electrode material.

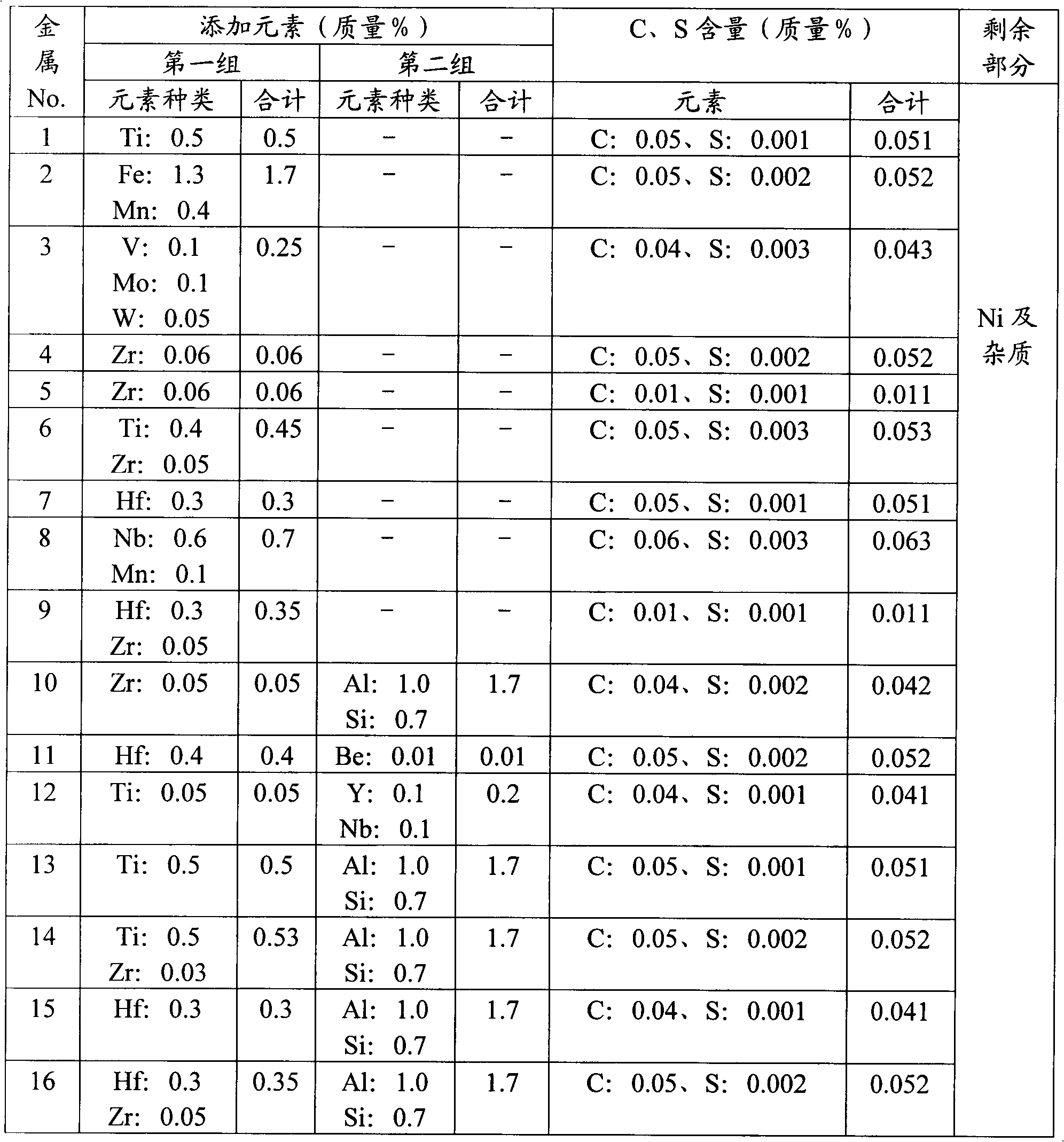

[0042] Table 1

[0043]

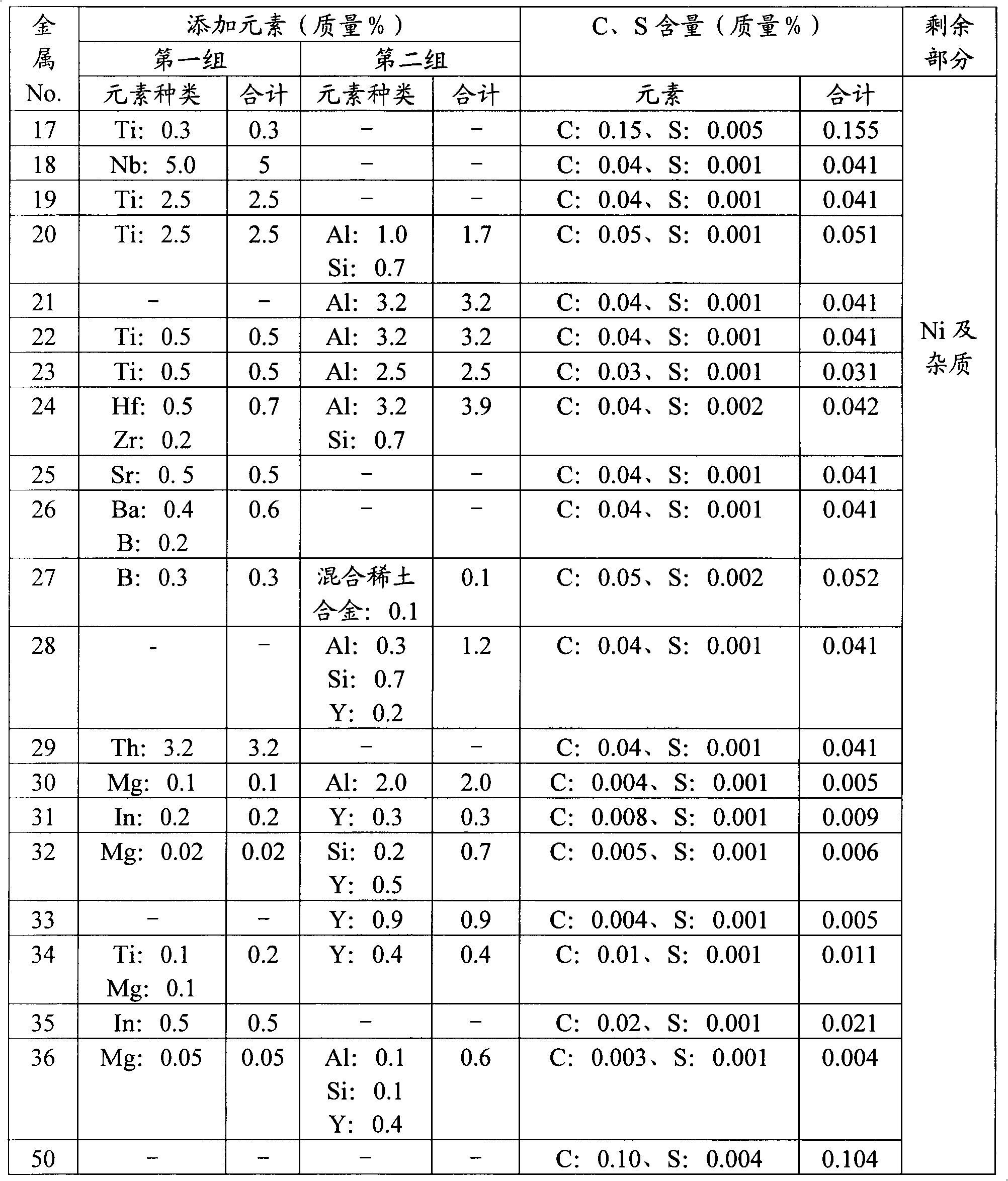

[0044] Table 2

[0045]

[0046]

[0047] The linear electrode material was produced as follows. A metal solution containing the components shown in Tables 1 and 2 was prepared using a general vacuum melting furnace, the temperature of the solution was appropriately adjusted, and an ingot was obtained by vacuum casting. Process the obtained ingot to 5.5 mm by hot rolling The diameter of the wire i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron work function | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com