Electrode for discharge lamp, process for production of electrode for discharge lamp, and discharge lamp

A technology for discharge lamps and electrodes, which is applied in the manufacture of discharge tubes/lamps, electrode system manufacturing, and components of gas discharge lamps. Cathode drop voltage, improved sputtering resistance, and power saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0203]

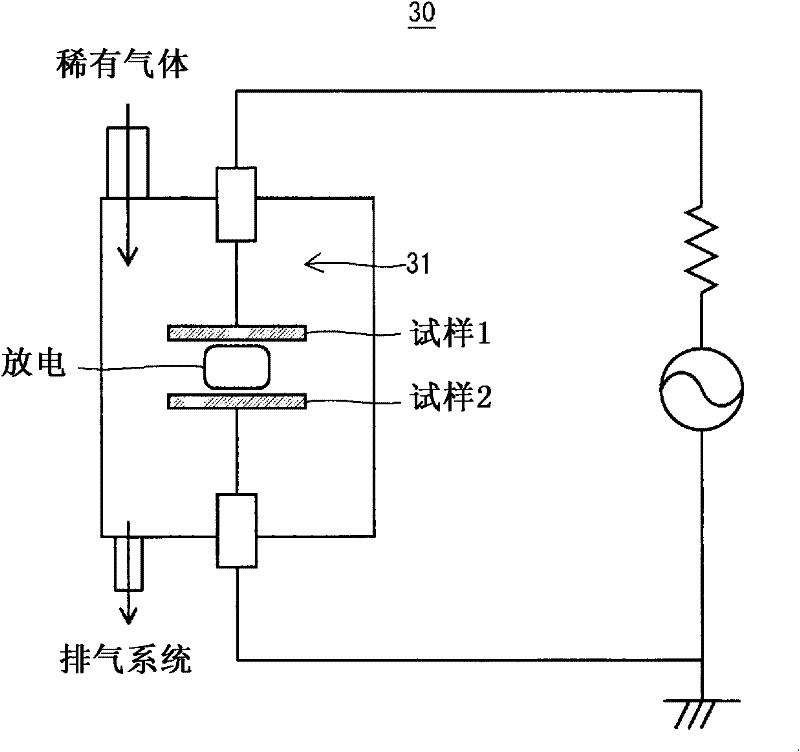

[0204] Set sample A to figure 2 The open circuit battery discharge measurement device 30 is shown in the vacuum chamber 31 . Set metal molybdenum as the counter electrode. The distance between the sample A and the counter electrode was 1.45 mm. First the vacuum chamber 31 is evacuated to 3×10 -4 Pa, and then filled with argon until it reaches 4400Pa.

[0205] Then, if Figure 45As shown, a 10Hz AC voltage was applied with a peak-to-peak value of 600V for glow discharge. The cathode drop voltage of Sample A was measured and found to be 152 V when the Pd product was about 4.8 Torr·cm. Here, P is the air pressure in the vacuum chamber, and d is the distance between the cathode and the anode. In contrast, the cathode drop voltage of metal molybdenum is 212V. Therefore, it can be seen that the cathode drop voltage of sample A is 28% lower than that of metal molybdenum.

Embodiment 2

[0207]

[0208] In the aforementioned , the sample B was obtained in the same manner except that the heat treatment temperature was set to 1340°C. The covered portion of sample B was green. According to X-ray diffraction, the covering part is only 12CaO·7Al 2 o 3 The structure is a mayenite compound. In addition, the electron density of the mayenite compound in the covering part obtained by the Kubelka-Munck method from the diffuse reflectance spectrum is 5.8×10 19 cm -3 . In addition, the surface shape when observed with a SEM at a magnification of 6000 times has a three-dimensional concave-convex structure with a domain diameter of 0.1 to 5 μm.

[0209] Then, set sample B to figure 2 The open circuit battery discharge measurement device 30 is shown in the vacuum chamber 31 . Set metal molybdenum as the counter electrode. The distance between the sample B and the counter electrode was 1.13 mm. Evacuate the vacuum chamber to 3×10 -4 Pa, and then filled with argon ...

Embodiment 3

[0212]

[0213] In the aforementioned , sample C was obtained in the same manner except that the holding time at 1300° C. was set to 2 hours. The covered portion of sample C was green. According to X-ray diffraction, the covering part is only 12CaO·7Al 2 o 3 The structure is a mayenite compound. In addition, the electron density of the mayenite compound in the covering part obtained by the Kubelka-Munck method from the diffuse reflectance spectrum is 3.2×10 19 cm -3 . In addition, the surface shape when observed with a SEM at a magnification of 6000 times has a three-dimensional concave-convex structure with a domain diameter of 0.2 to 6 μm.

[0214] Then, set sample C to figure 2 The open circuit battery discharge measurement device 30 is shown in the vacuum chamber 31 . Set metal molybdenum as the counter electrode. The distance between sample C and the counter electrode was 1.45 mm. Evacuate the vacuum chamber to 3×10 -4 Pa, and then filled with argon until it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com