Waveguide welding fixture

A welding tool and waveguide technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of disconnection of slot waveguide antenna, and achieve the effect of reducing heat capacity, improving yield and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

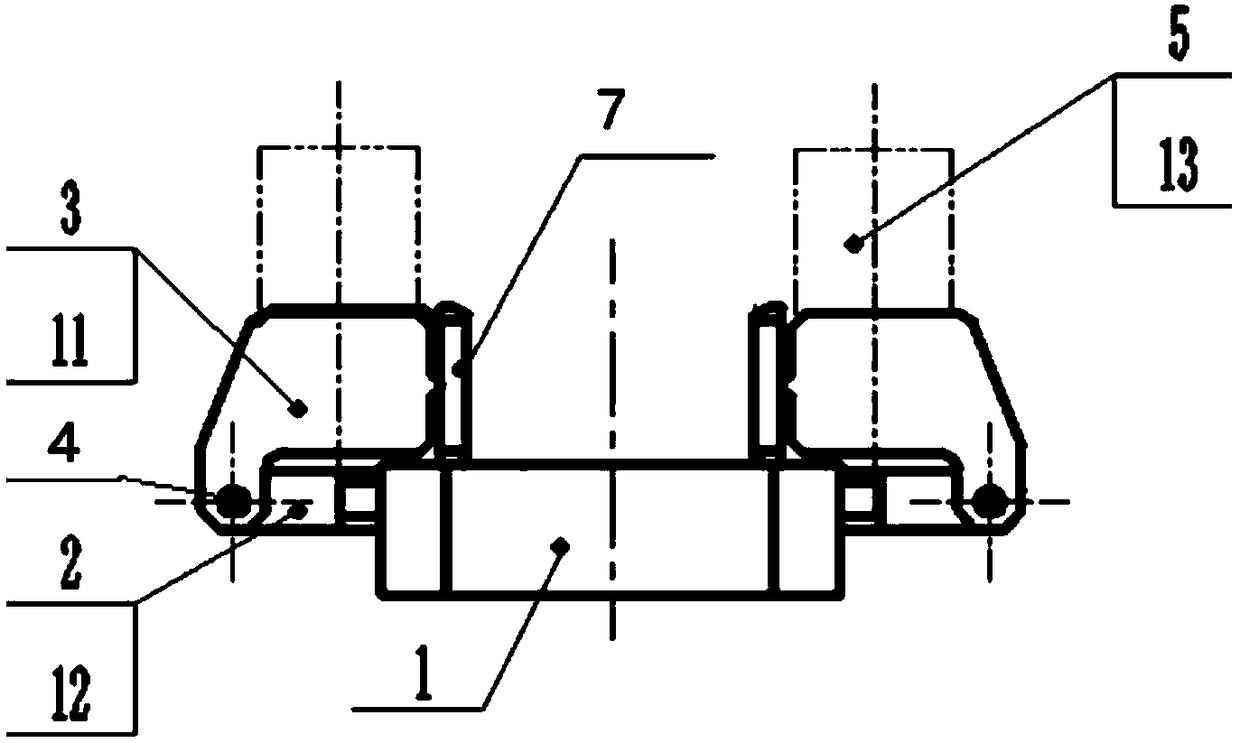

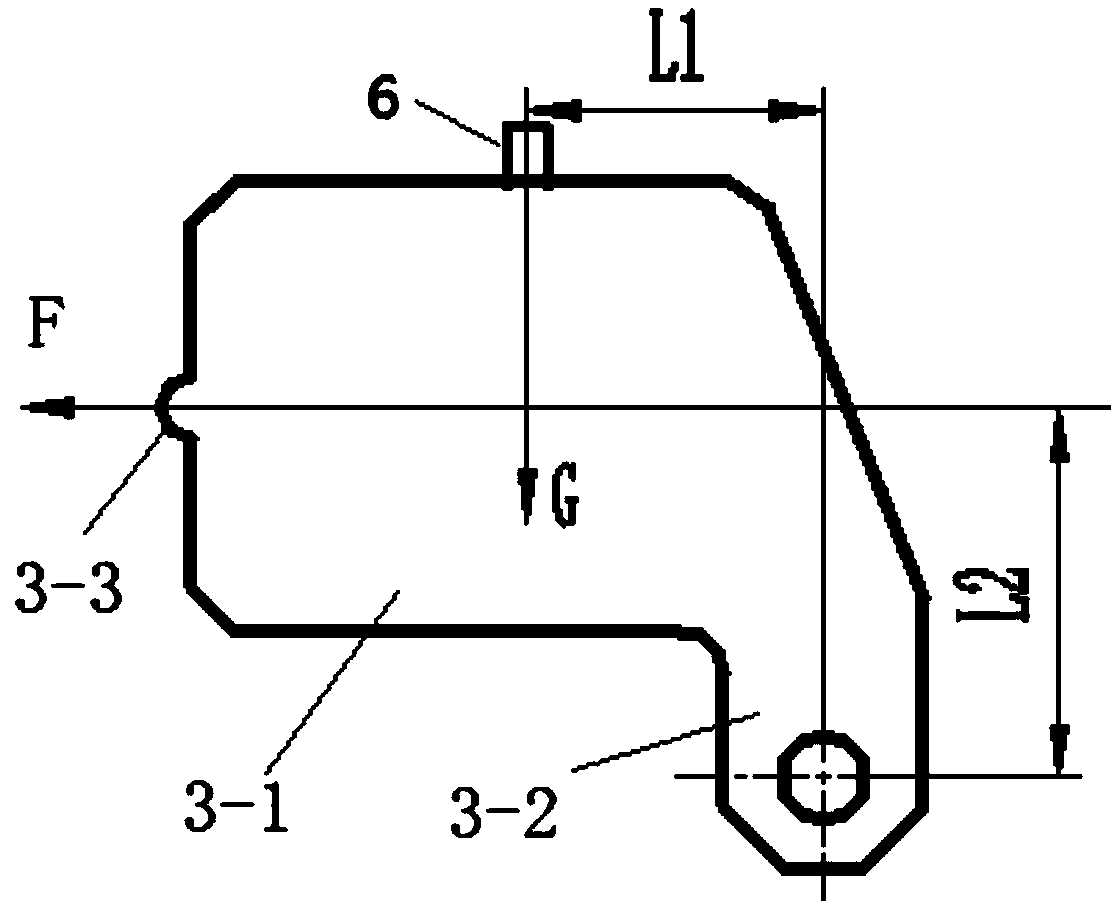

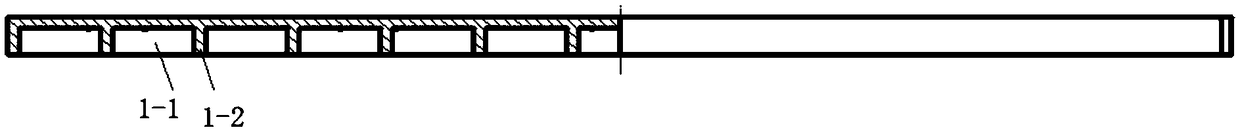

[0030] combine Image 6 , an aerospace product slot waveguide antenna, including a welding part 200, a cover plate 300 fixedly connected with the first welding part 200; a vertical weld 201 on the primary welding part; The part 100 is welded together with the primary welding part 200, and the secondary welding seam 301 is along the length of the secondary part and the length direction of the primary welding part 200, that is, the horizontal direction;

[0031] The slot waveguide has a total length of 622.5mm, a width of 37.7mm, and a wall thickness of only 0.8mm. It is a typical thin-walled structure with an excessively large aspect ratio, and welding deformation is very easy to occur during welding. The geometric dimension accuracy of the inner cavity of the secondary welding part 100 is required to be ±0.02-±0.05 mm, and the flatness of the side wall of the waveguide cavity after welding is required to be 0.1 mm. according to Figure 7 As shown, the waveguide is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com