A key switch device supported by sheet metal scissor feet with elastic hook limit structure

A technology of elastic hook and limit structure, which is applied to electric switches, contact operating mechanisms, electrical components, etc., can solve the problems of low injection precision, low stamping precision, injection defects, and low-profile design, and achieve low-profile, The effect of reducing defect rate and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

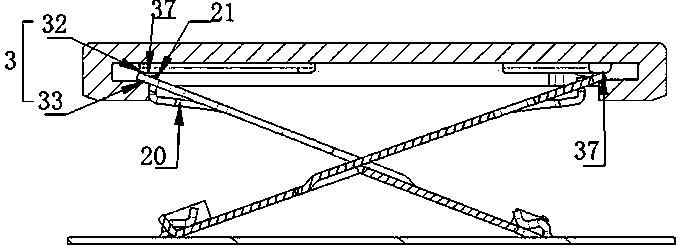

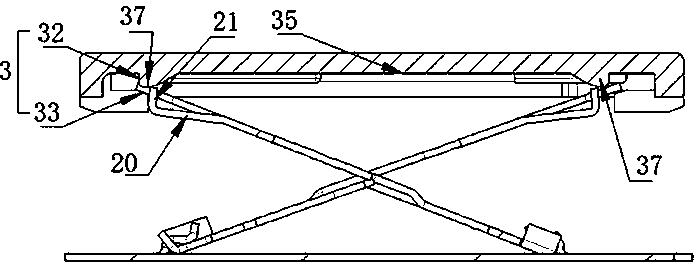

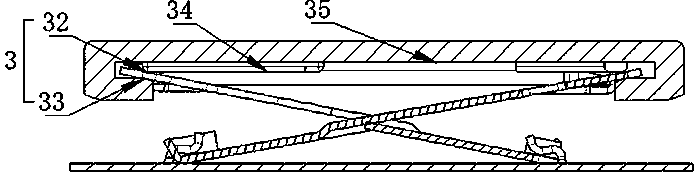

[0096] Such as image 3 --- Figure 48 As shown, a key switch device supported by a sheet metal scissors foot with an elastic hook limit structure of the present invention includes a keycap, a reset element, a switch circuit with a switch, a support plate with a matching part, and scissors with an upper and lower matching part. The foot support, the scissor foot support is respectively connected with the keycap and the support plate through the upper and lower matching parts to rotate or slide, and the scissor foot support forms a synchronous linkage support structure through the transmission of force between each other to ensure that the keycap is parallel to the support plate. Lifting movement, the scissors support 16 is stamped and formed on the metal plate surface; the scissors support 16 is formed with elastic sheet metal elastic arms 20; the scissors support 16 has a stamped and formed scissors anti-off structure;

[0097] The key cap 1 is provided with a key limiting b...

Embodiment 2

[0122] see Figure 18 , Figure 19 , the scissors lower plane 17 of the metal inner scissors foot 28 is located on the outside of the scissors upper plane 19, the scissors lower plane 17 of the metal outer scissors foot 31 is respectively located at the inner side and the lower side of the scissors upper plane 19, and the scissors lower plane 17. The upper plane 19 of the scissors is connected by a length bending edge 41 , and the length bending edge 41 is along the length direction of the scissors leg 23 .

[0123] The inner scissors supporting part 18 of the metal inner scissors foot 28 located on the outer side of the scissors upper plane 19 is perpendicular to the length direction of the scissors arm 23, and the metal outer scissors foot 31 has an end surface extending plate 43, and the end surface extends the plate surface The cantilever end face of 43 is perpendicular to the length direction of scissors foot arm 23.

[0124] There is an inner reinforcing flange 42 on t...

Embodiment 3

[0132] Such as Figure 23 , Figure 24 , Figure 25 , Figure 26 1. Between the left and right end surfaces of the sheet metal scissors support, and near the upper end surface of the sheet metal scissors support, there is a cantilever notch through hole 20a that runs through the sheet metal scissors support plate, and at the left end of the cantilever notch through hole 20a There is a sheet metal elastic arm 20 extending to the other end face on the face or the right end face.

[0133] Such as Figure 23 , Figure 24 1. The sheet metal elastic arm 20 is a cantilever, and the scissors anti-off structure is located at the end of the sheet metal elastic arm 20 cantilever.

[0134] Such as Figure 25 , Figure 26 1. The sheet metal elastic arm 20 is rigidly connected to the left and right end faces of the sheet metal scissors foot support, and the scissors anti-off structure is located on the sheet metal elastic arm 20, but it is best to locate the scissors anti-off structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com