Refrigerator factory inspection method, refrigerator factory inspection device and refrigerator

A technology for ex-factory inspection and refrigerator, which is applied in the field of refrigerator ex-factory inspection, refrigerator, and refrigerator ex-factory inspection device, which can solve problems such as low accuracy, difficult detection of load faults, and long refrigerator inspection time, so as to improve accuracy and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

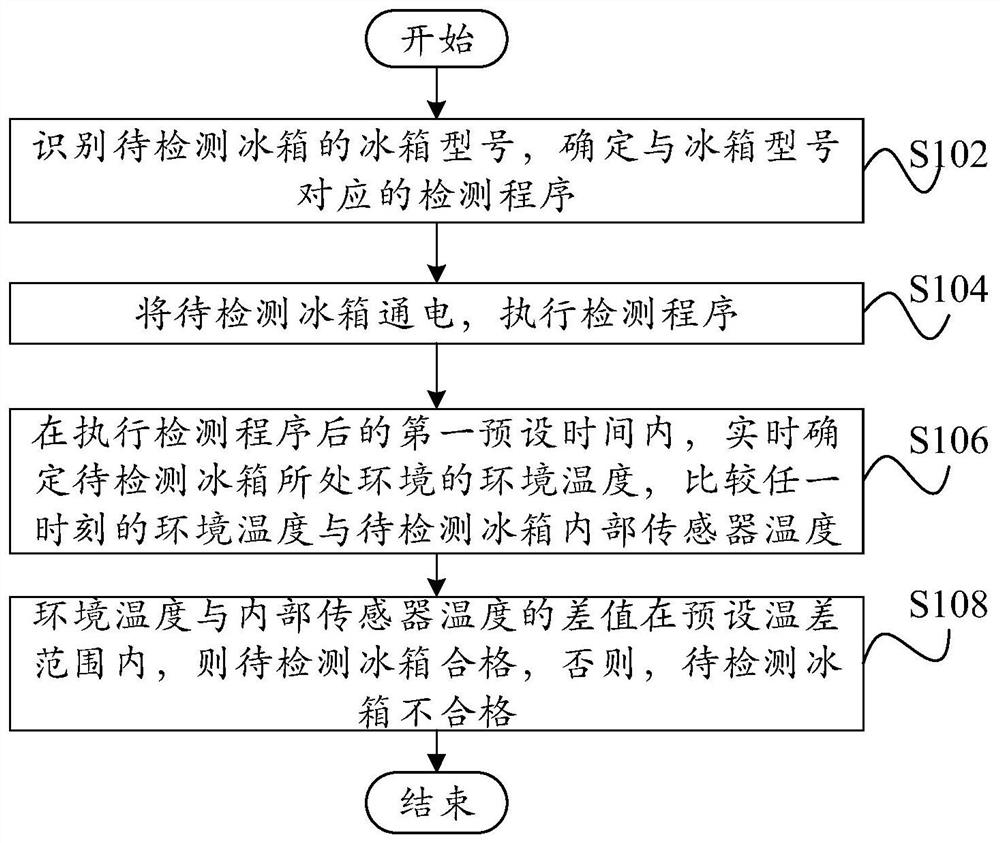

[0066] Such as figure 1 As shown, step S102, identify the refrigerator model of the refrigerator to be tested, and determine the detection program corresponding to the refrigerator model; step S104, power on the refrigerator to be tested, and execute the detection program; step S106, after the first preset time after the detection program is executed, Within, determine the ambient temperature of the environment where the refrigerator to be detected is located in real time, and compare the ambient temperature at any moment with the temperature of the internal sensor of the refrigerator to be detected; Step S108, if the difference between the ambient temperature and the temperature of the internal sensor is within the preset temperature difference range Otherwise, the refrigerator to be tested is unqualified. By comparing the ambient temperature at any time and the temperature of the internal sensor of the refrigerator to be tested, the performance and status of the refrigerator ...

Embodiment 2

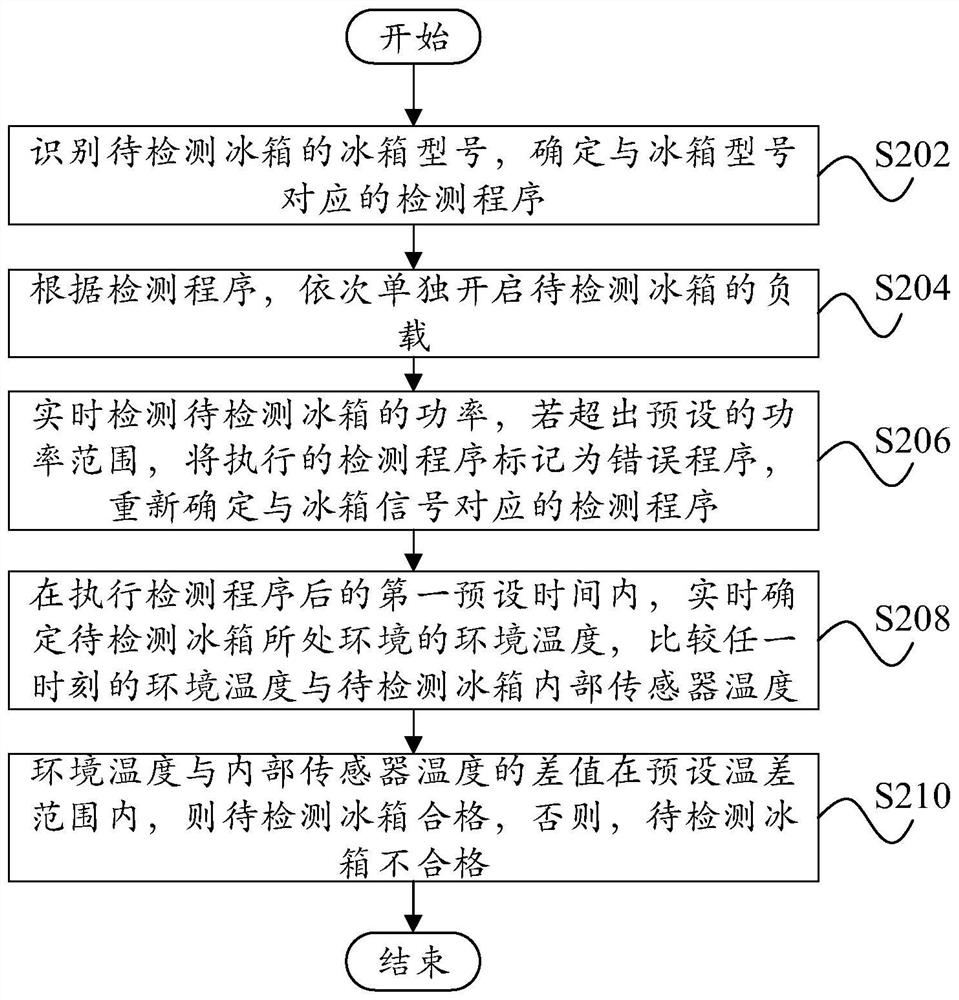

[0068] Such as figure 2 As shown, in step S202, identify the refrigerator model of the refrigerator to be detected, and determine the detection program corresponding to the refrigerator model; step S204, according to the detection program, turn on the load of the refrigerator to be detected in sequence; step S206, detect the power of the refrigerator to be detected in real time, If at any time, the power exceeds the preset power range corresponding to any time, then mark the detection program being executed as an error program, and redetermine the detection program corresponding to the refrigerator model; Within a set time, determine the ambient temperature of the environment where the refrigerator to be detected is located in real time, and compare the ambient temperature at any time with the temperature of the internal sensor of the refrigerator to be detected; step S210, if the difference between the ambient temperature and the temperature of the internal sensor is within t...

Embodiment 3

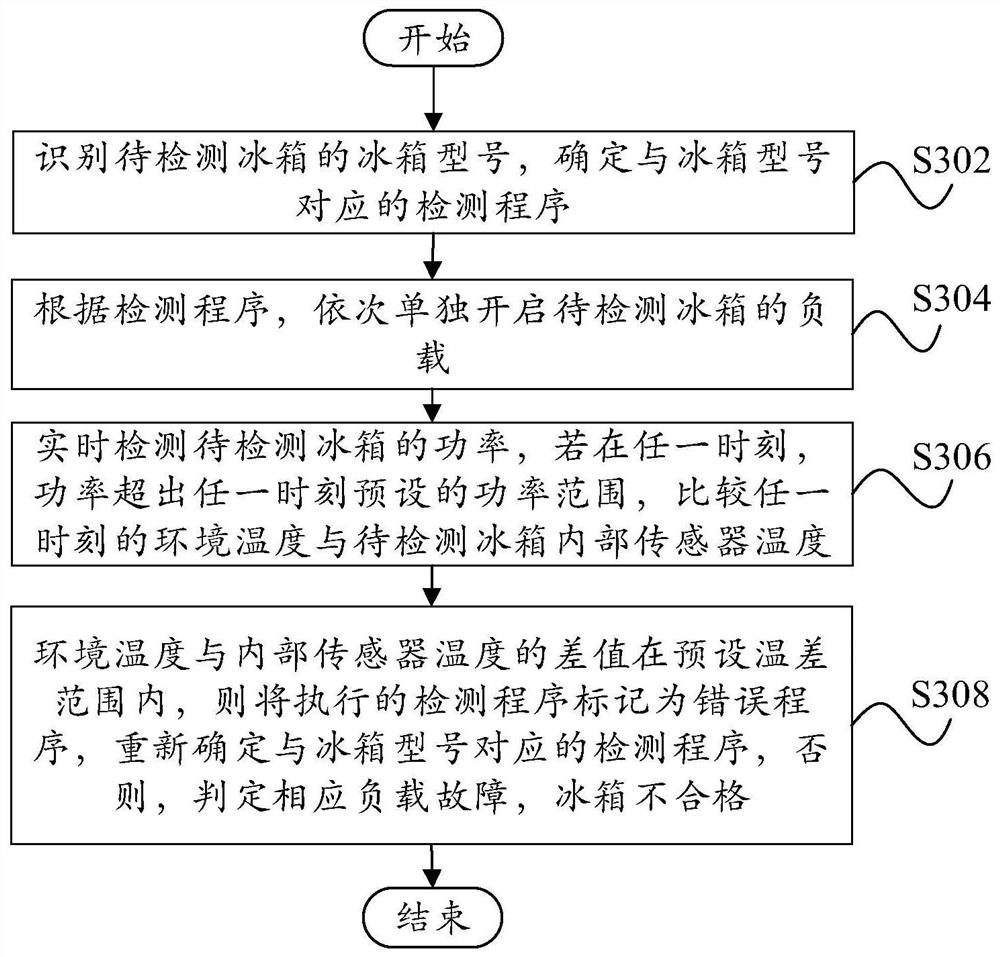

[0070] Such as image 3 As shown, in step S302, identify the refrigerator model of the refrigerator to be detected, and determine the detection program corresponding to the refrigerator model; step S304, according to the detection program, turn on the load of the refrigerator to be detected in sequence; step S306, detect the power of the refrigerator to be detected in real time, If at any moment, the power exceeds the preset power range corresponding to any moment, compare the ambient temperature at any moment with the internal sensor temperature of the refrigerator to be detected; step S308, if the difference between the ambient temperature and the internal sensor temperature is within the preset temperature difference range If the detected program is not within the range, mark the executed detection program as an error program, and re-determine the detection program corresponding to the refrigerator model. Otherwise, it is determined that the corresponding load is faulty and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com