Motor abnormal detection circuit and control method thereof

A detection circuit and abnormal detection technology, applied in emergency protection circuit devices, electrical components, etc., can solve problems such as poor motor safety and overload detection, and achieve the effects of improving safety, improving reliability, and reducing the rate of factory defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

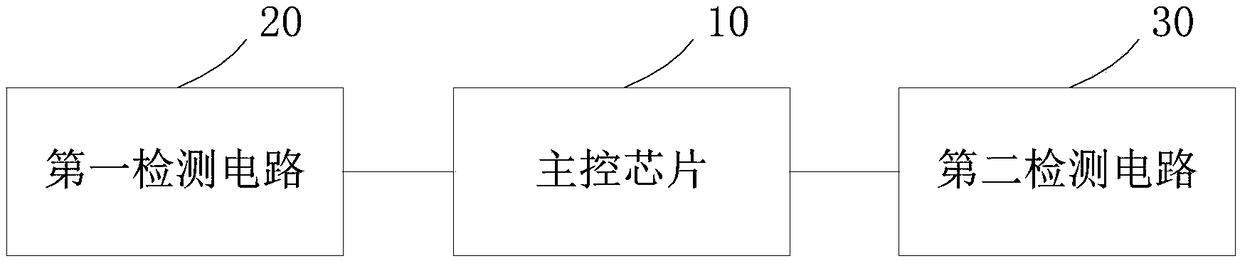

[0025] Based on the motor abnormality detection circuit described above, the preferred embodiment 2 of the present invention also provides a control method for the motor abnormality detection circuit, including: the first detection circuit samples the DC bus current of the motor controller and provides an input voltage signal The second detection circuit determines the motor overload state according to the input voltage signal provided by the first detection circuit; the main control chip controls the start and stop of the motor according to the motor overload state determined by the second detection circuit.

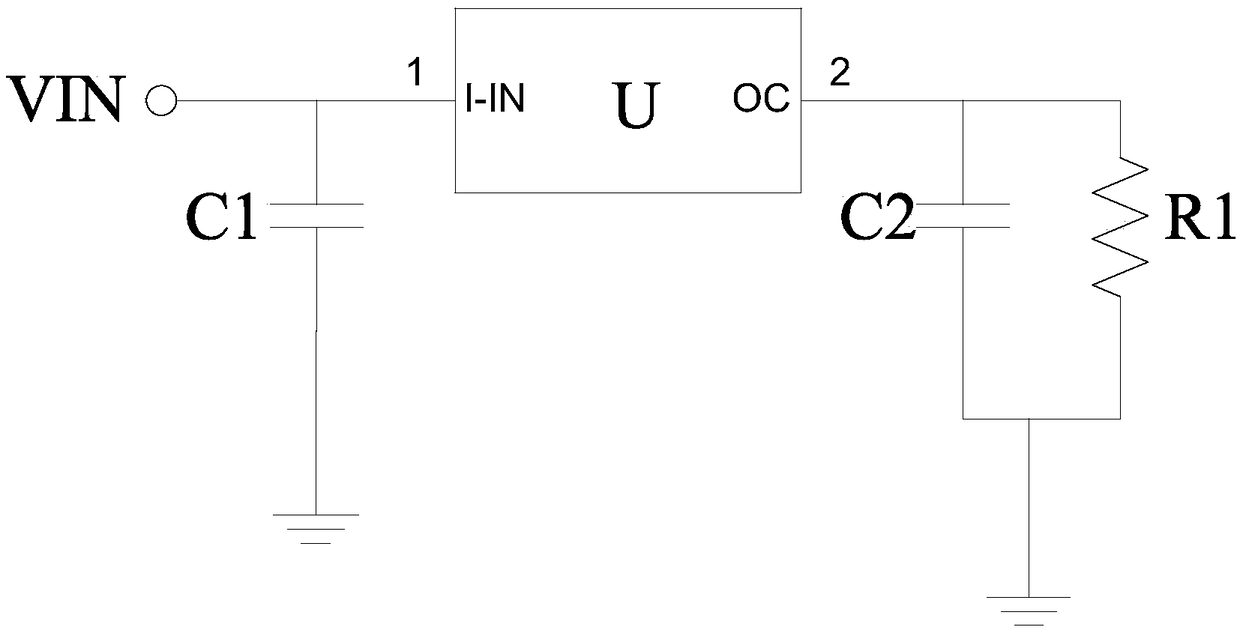

[0026] Further, when the input voltage signal provided by the first detection circuit is greater than or equal to the first voltage threshold, it is determined that the motor overload state is the first state (normal state), and the main control chip controls the second detection circuit to charge the overload protection capacitor; When the input voltage signal provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com