Impeller with retaining mechanism on impeller disk and water-wheel aerator with retaining mechanism impeller

A technology of water wheel aerator and impeller disc, which is applied in fish farming, application, animal husbandry, etc., and can solve the problems of strength fracture of the hole, expensive stainless steel, and stainless steel square tubes should not be too thin, etc., to achieve easy assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

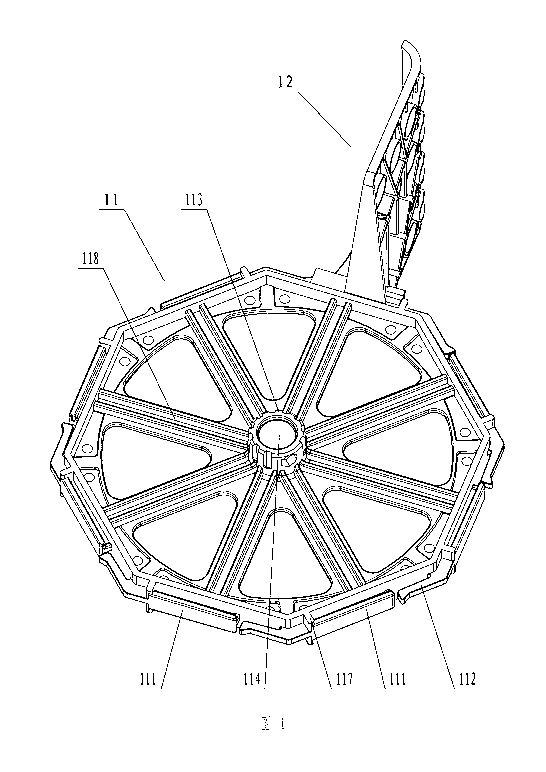

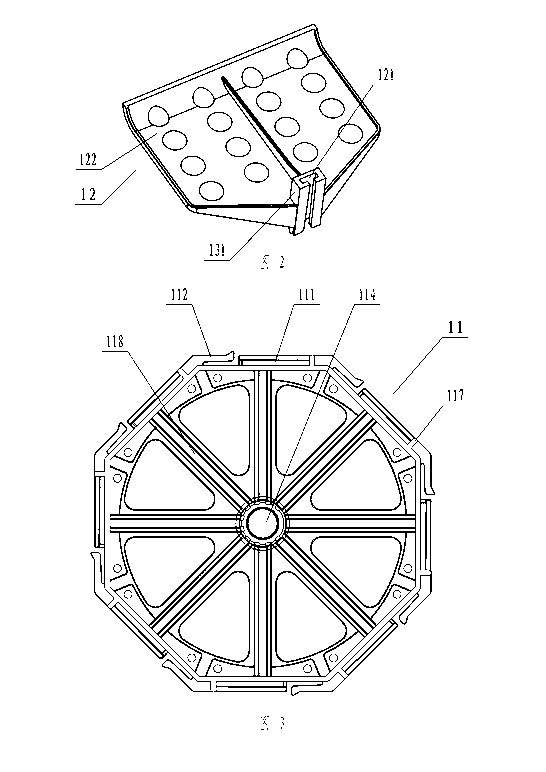

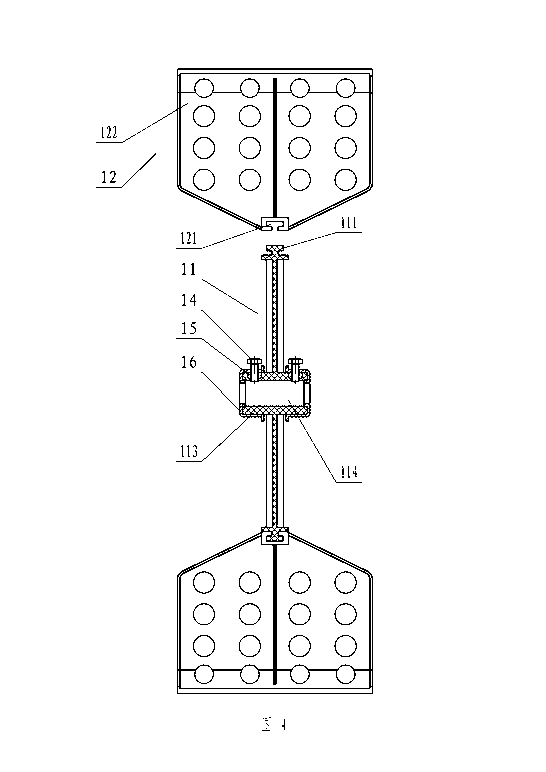

[0051] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-19 :

[0052] An impeller with a backstop mechanism for the impeller disc, mainly composed of blades and impeller discs, see Figure 1-4 , The blade mounting part 131 can be provided with a C-shaped chute 121 to cooperate with the T-shaped guide rail 111 on the impeller disc; the impeller disc 11 can have a stop-back mechanism that is injection molded together. The impeller backstop mechanism is: the impeller disc 11 is a polygonal window-shaped structure, and each straight side of the window is connected to the center shaft hole 114 by spokes 118, and each straight side is provided with a T-shaped guide rail 111, T-shaped There is a stopper 117 at the rear end of the guide rail, and there is an elastic stop strip 112 at the front end of the T-shaped guide rail. One end of the elastic stop strip is injection-molded with the straight ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com