Assembly fixture of armature assembly for electrohydraulic servo valve

A technology for electro-hydraulic servo valves and assembly fixtures, which is applied in the direction of servo motor components, workpiece clamping devices, manufacturing tools, etc., can solve the problems that affect the reliability and performance of electro-hydraulic servo valves, large spring thin-wall deformation, and low assembly efficiency. High-level problems, to achieve the effect of reliability, large interference, and parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

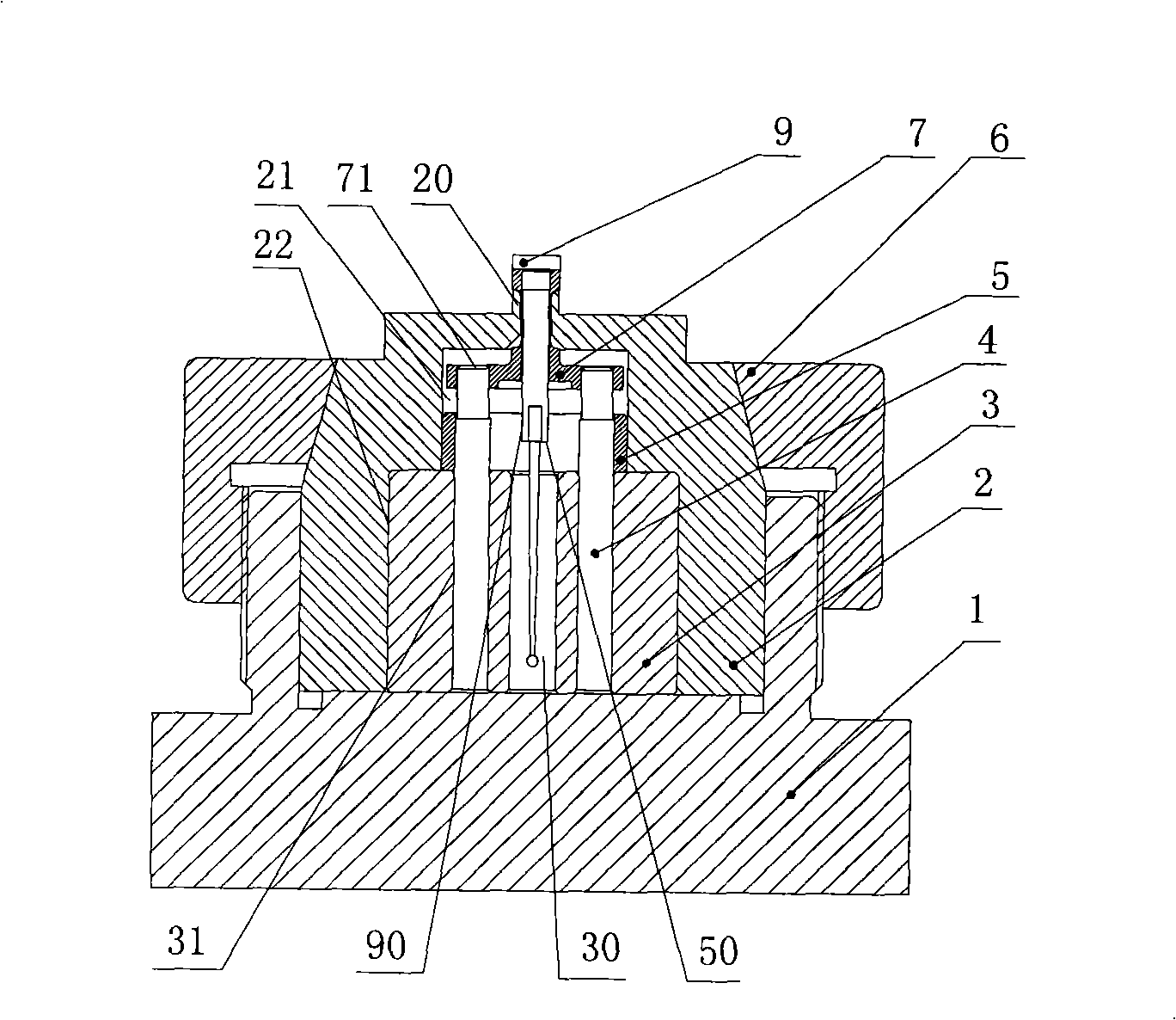

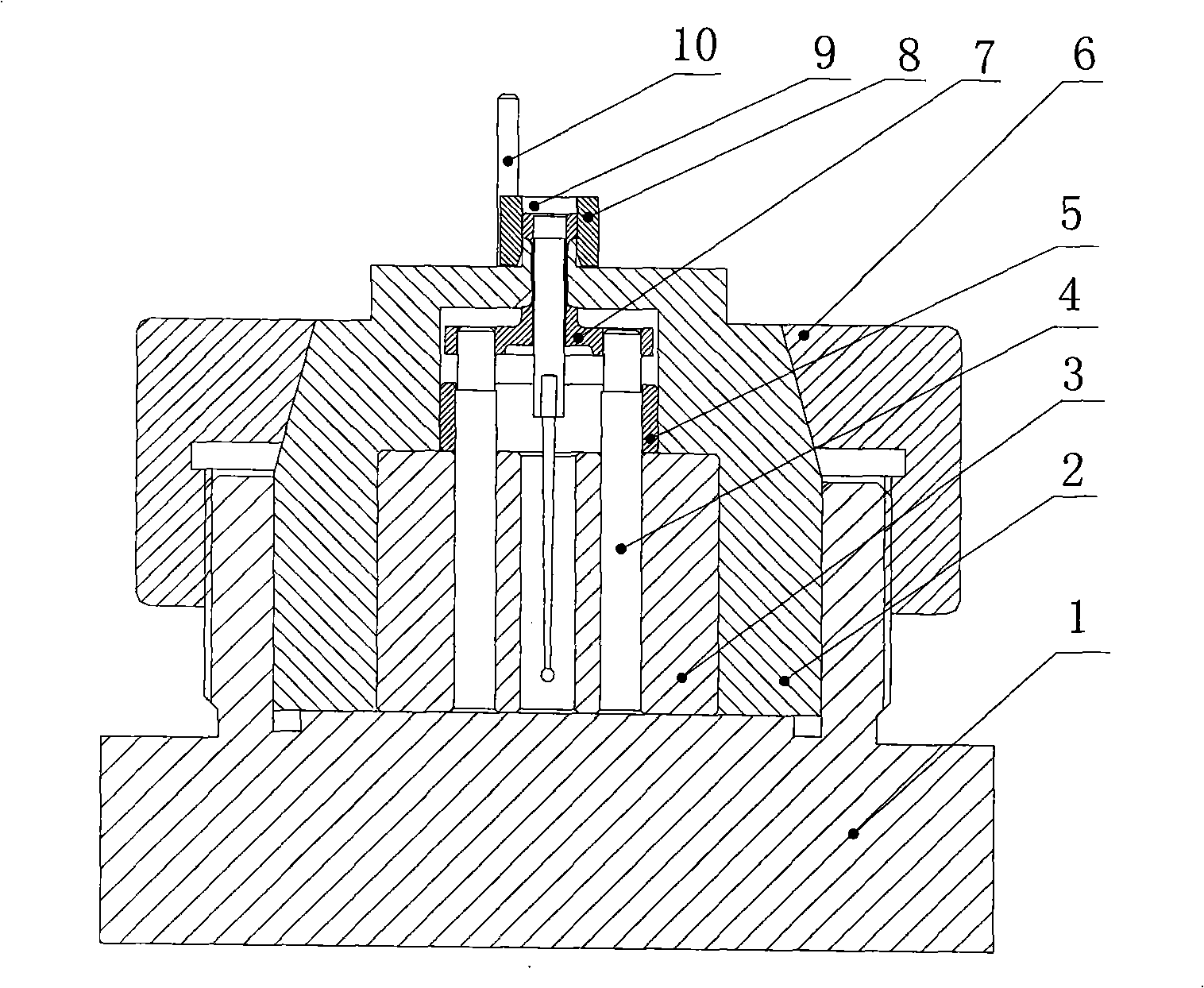

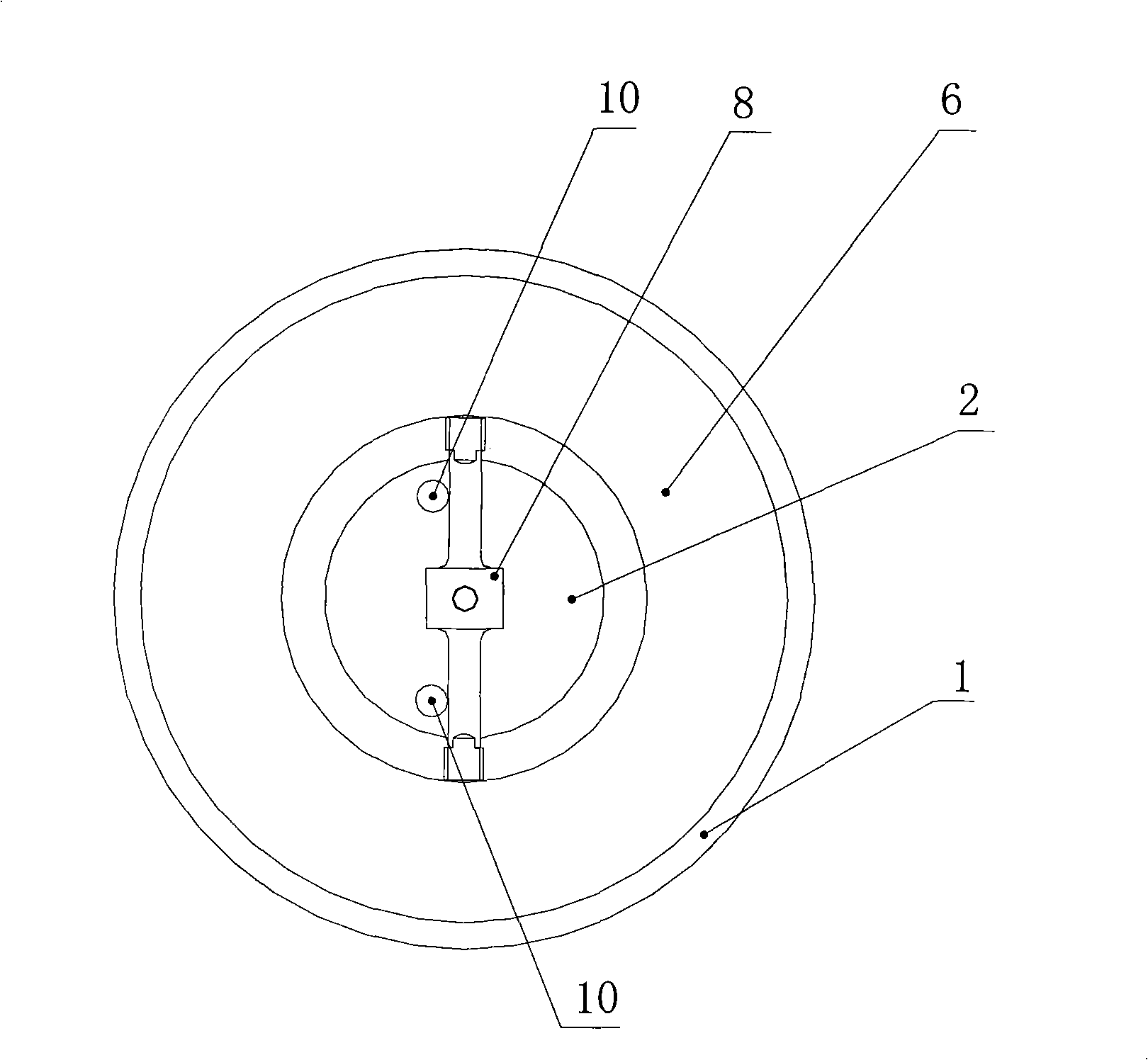

[0014] The armature assembly to be assembled by the assembly jig for the armature assembly of the electro-hydraulic servo valve of the present invention consists of a baffle feedback rod 9 , a tube spring 7 with a shoulder and an armature 8 .

[0015] see figure 1 , 2 , 3. The assembly fixture for the armature assembly of the electro-hydraulic servo valve of the present invention includes a mounting seat 1, two left and right blocks 2, a positioning shaft 3, two first positioning pins 4, and a baffle positioning sleeve 5 , a locking nut 8 and two second positioning pins 10, wherein,

[0016] Mounting seat 1 is a cylindrical seat, and it is provided with screw thread on the outer peripheral surface of the cylindrical wall above the bottom.

[0017] The left and right blocks 2 are semicircular parts, and the lower part of the outer peripheral surface after they are assembled is adapted to the inner peripheral surface of the cylindrical wall of the mounting seat 1, and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com