Manufacturing equipment for metal wound gaskets

A technology for metal wound gaskets and manufacturing equipment, which is applied in metal processing equipment, manufacturing tools, metal processing, etc., and can solve the problems of ring 4a ring protrusion crushing, affecting product sealing performance, and winding ring 4a warping, etc. Achieve the effects of reduced installation difficulty, reduced scrap rate, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

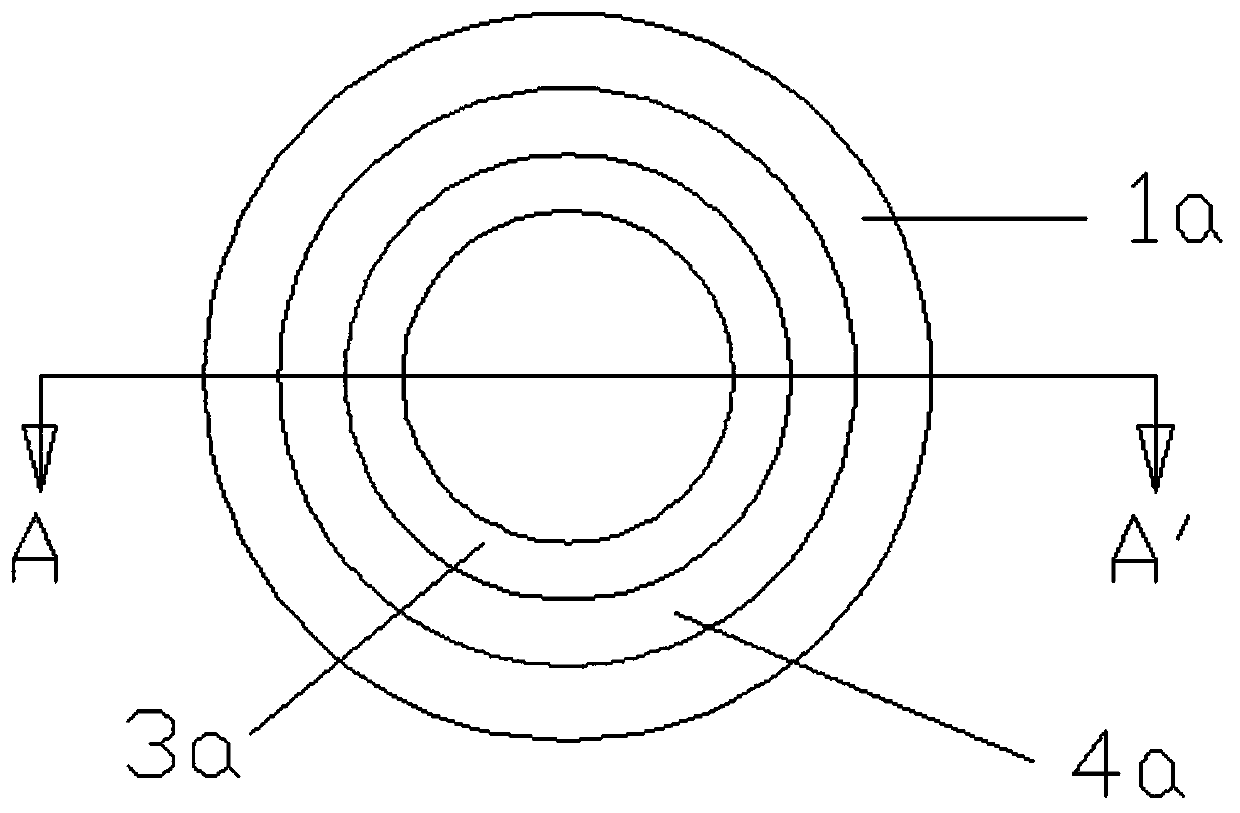

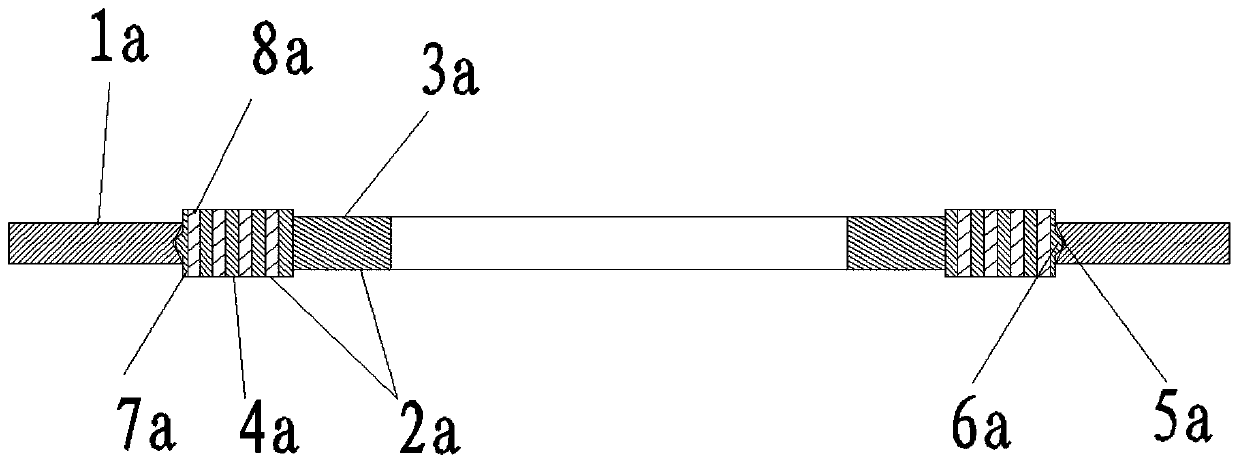

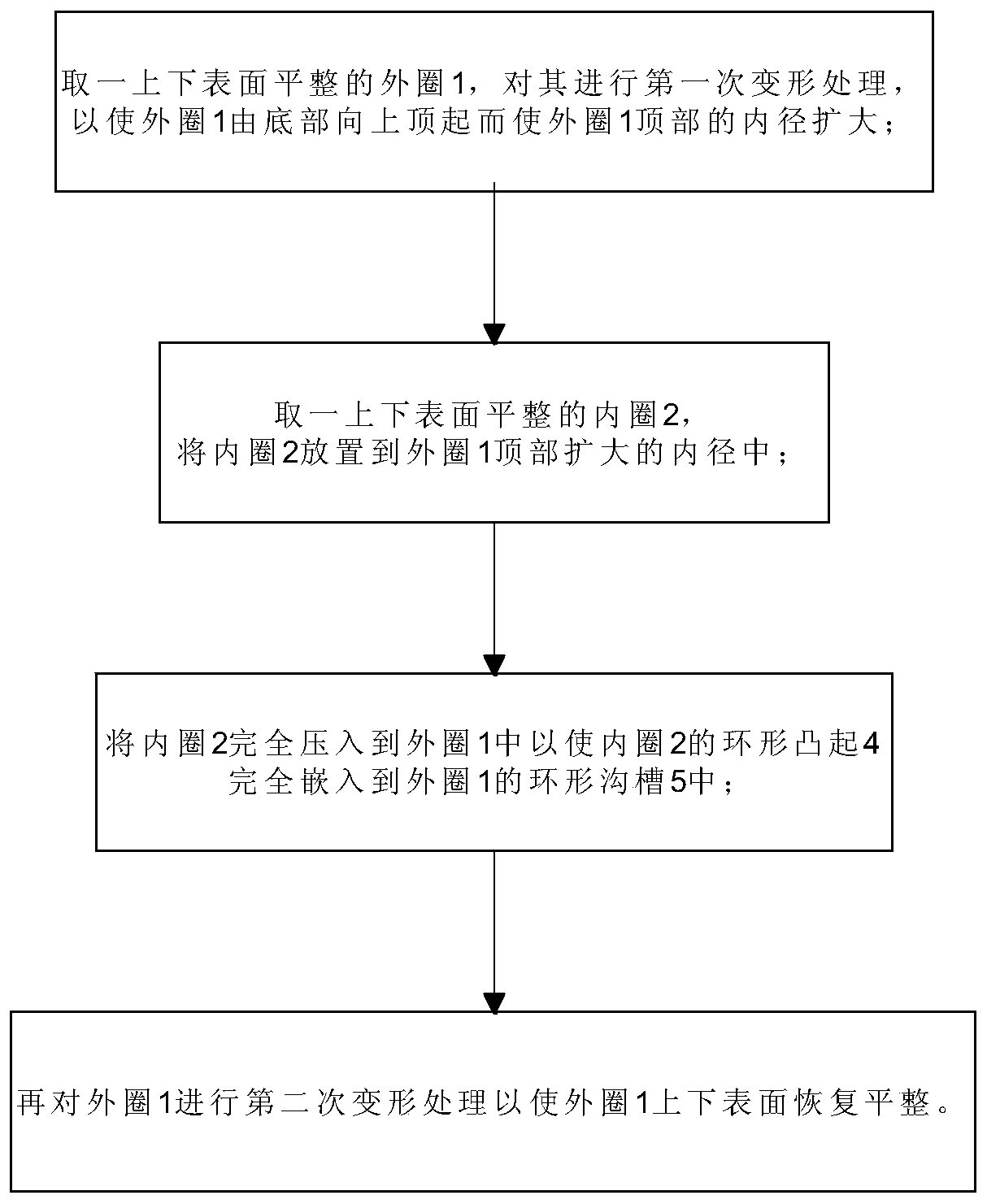

[0036] A manufacturing method of metal spiral wound gasket, which includes the following steps:

[0037] (1) Take an outer ring 1 with flat upper and lower surfaces, and perform the first deformation treatment on it, so that the outer ring 1 is raised from the bottom up and the inner diameter of the top of the outer ring 1 is enlarged;

[0038] (2) Take an inner ring 2 with flat upper and lower surfaces, and place the inner ring 2 in the enlarged inner diameter of the top of the outer ring 1;

[0039] (3) Fully press the inner ring 2 into the outer ring 1 so that the annular protrusion 4 of the inner ring 2 is completely embedded in the annular groove 5 of the outer ring 1;

[0040] (4) The outer ring 1 is deformed a second time to make the upper and lower surfaces of the outer ring 1 smooth.

[0041] Preferably, the first deformation treatment in the step (1) adopts the cold pressing treatment of the outer ring deforming mold 6, which includes a first upper mold 7 and a first lower mol...

Embodiment 2

[0045] A manufacturing equipment for metal spiral wound gaskets includes an outer ring automatic deformation device 22 and an inner and outer ring ring leveling device 23. The outer ring automatic deformation device 22 includes a first table body 24 and a set on the first table body 24. The first multi-station index plate 25. In this embodiment, the first multi-station index plate 25 is provided with six stations, and each station of the first multi-station index plate 25 is provided for placing The first lower mold 8 of the outer ring 1, above the first multi-station index plate 25 is provided with a first upper mold 7 driven by a first press 28, the first upper mold 7 and the first lower mold When the die 8 is pressed together, the outer ring 1 is deformed for the first time, so that the outer ring 1 is lifted from the bottom upwards and the inner diameter of the top of the outer ring 1 is enlarged. The inner and outer ring leveling device 23 includes a device for completely r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com