Anti-interference gear and rolling cutter thereof used for machining

An anti-interference, gear technology, applied in the direction of gear tooth manufacturing tools, gear tooth manufacturing devices, components with teeth, etc., can solve the problems of gear meshing damage, inability to rotate, shortening the life of gears, etc., to improve the service life, The effect of reducing the amount of interference and making it easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

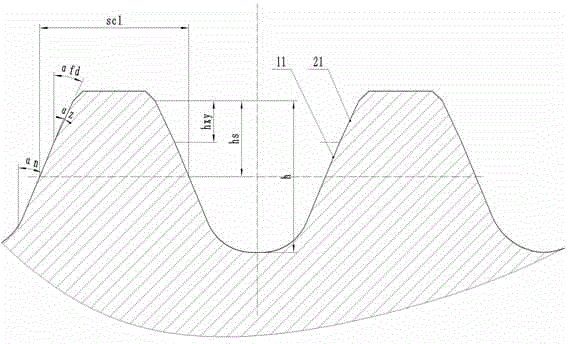

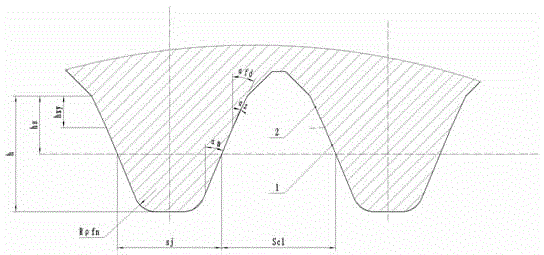

[0037] The specific values of the parameters of the anti-interference gear and its hob for processing are: pressure angle a n=25°, interference amount △δ=0.02, modulus m=0.1, trimming height h- xy =21 (㎝), full tooth height h=78 (㎝), tooth top height h s =39 (㎝), arc tooth thickness s c1 =70.3, Xuan long s j =76.7, fillet Rp fn =25 (㎝);

[0038] Calculated by the formula, it can be known that a fd =44.1°, a z =19.1°.

Embodiment 2

[0039] Implementation example 2, the specific values of each parameter of the anti-interference gear and hob used for processing are: interference amount △δ=0.09, modulus m=0.2, other parameters are the same as implementation example 1,

[0040] It can be known by the formula that a fd =57.5°, a z =32.5°.

Embodiment 3

[0041] Implementation example three, the specific values of each parameter of the anti-interference gear and hob used for processing are: interference amount △δ=0.045, modulus m=0.2, other parameters are the same as implementation example one,

[0042] It can be known by the formula that a fd =45.8°, a z =20.8°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fillet | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com