Compressor housing for supercharger

A technology of compressor housing and supercharger, which is applied to machines/engines, components of pumping devices for elastic fluids, mechanical equipment, etc., can solve problems such as impeller damage, achieve simple structure, reduce cost, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

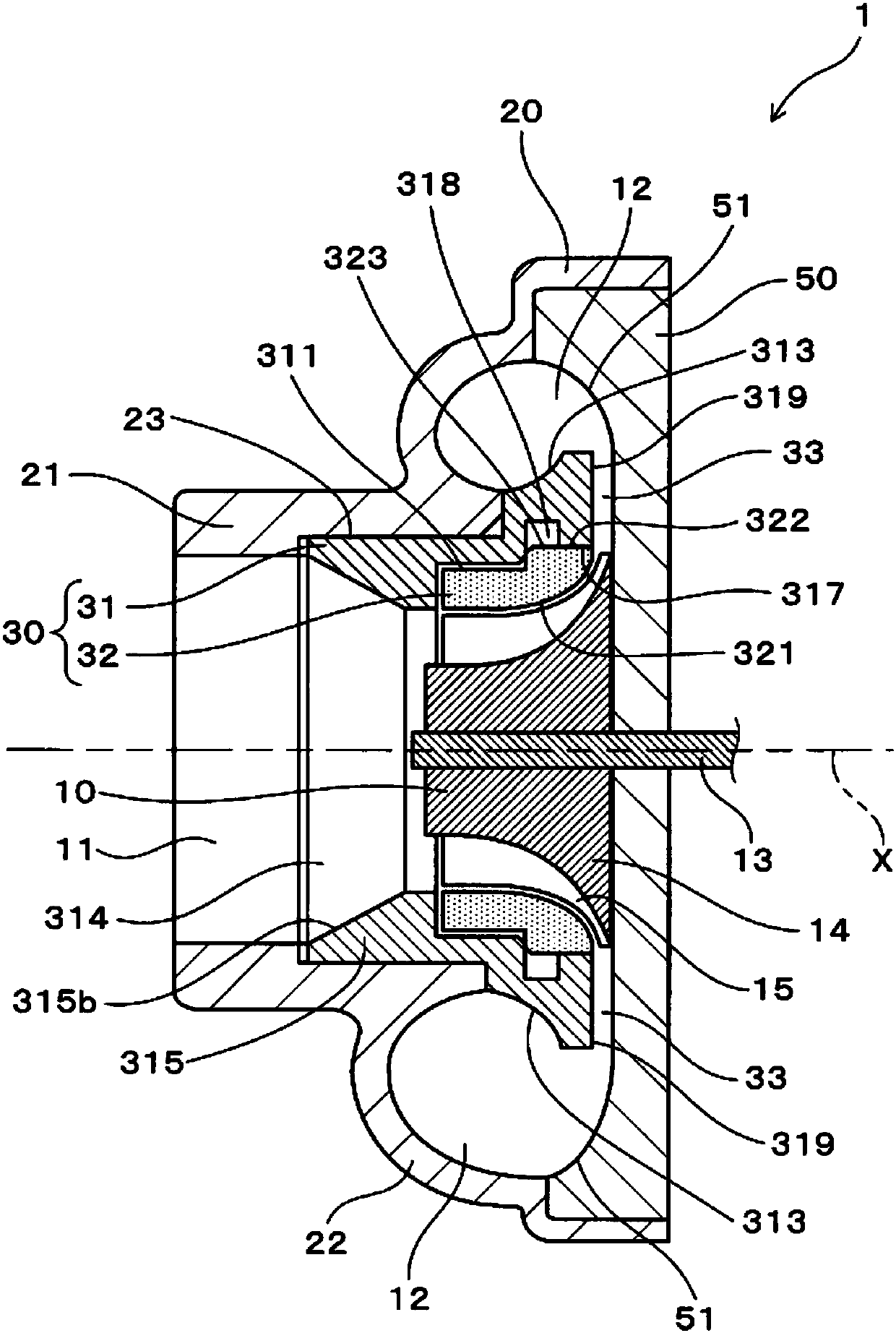

[0061] use Figure 1 to Figure 5 The compressor casing for the supercharger of this example will be described.

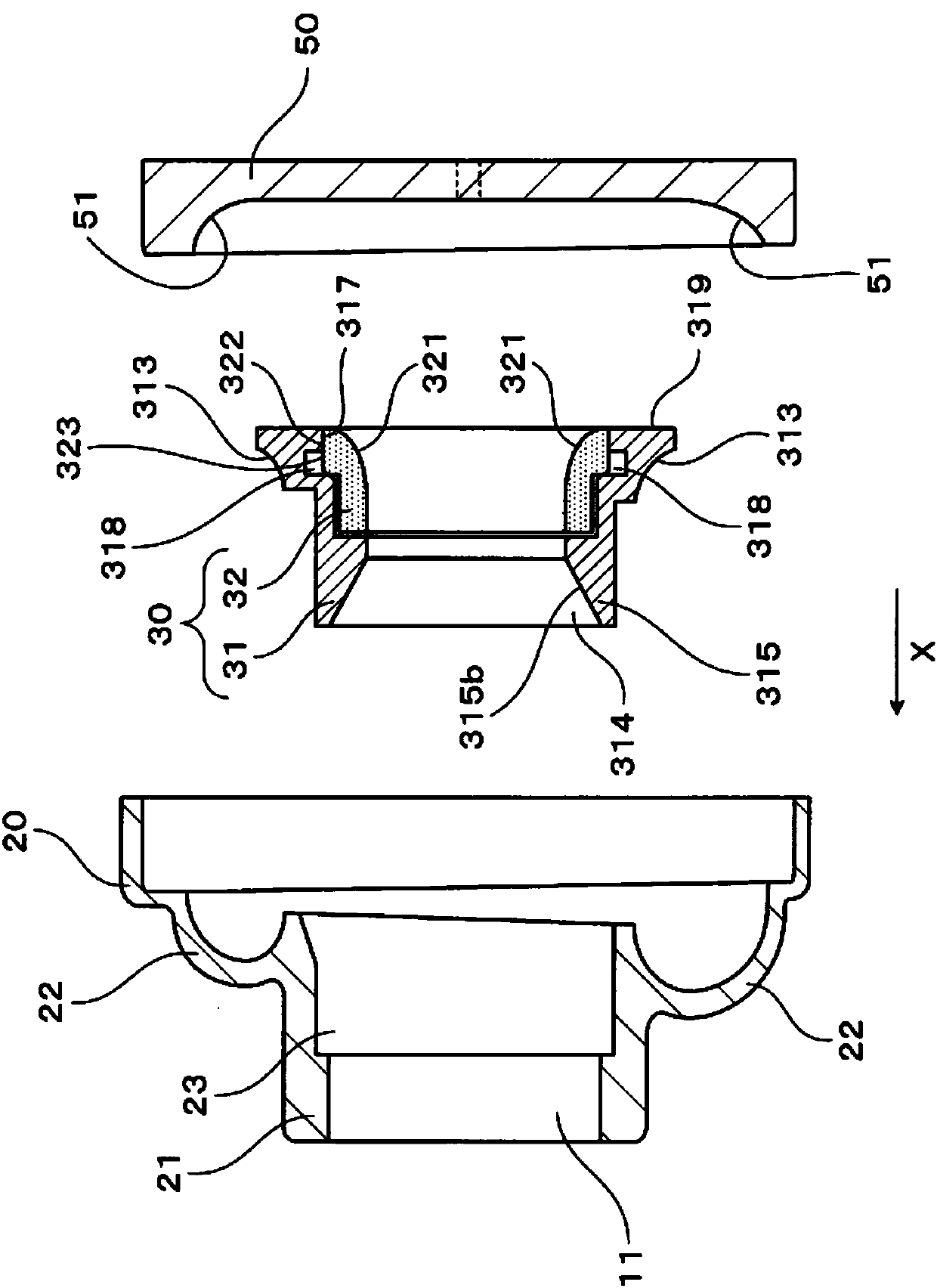

[0062] like figure 1 As shown, a compressor housing 1 for a supercharger (hereinafter, also referred to as “compressor housing 1 ”) of this example is configured to accommodate an impeller 10 and includes a scroll portion 20 and a shroud portion 30 .

[0063] The scroll portion 20 has: an air inlet 11 through which air is sucked toward the impeller 10; To the vortex chamber 12.

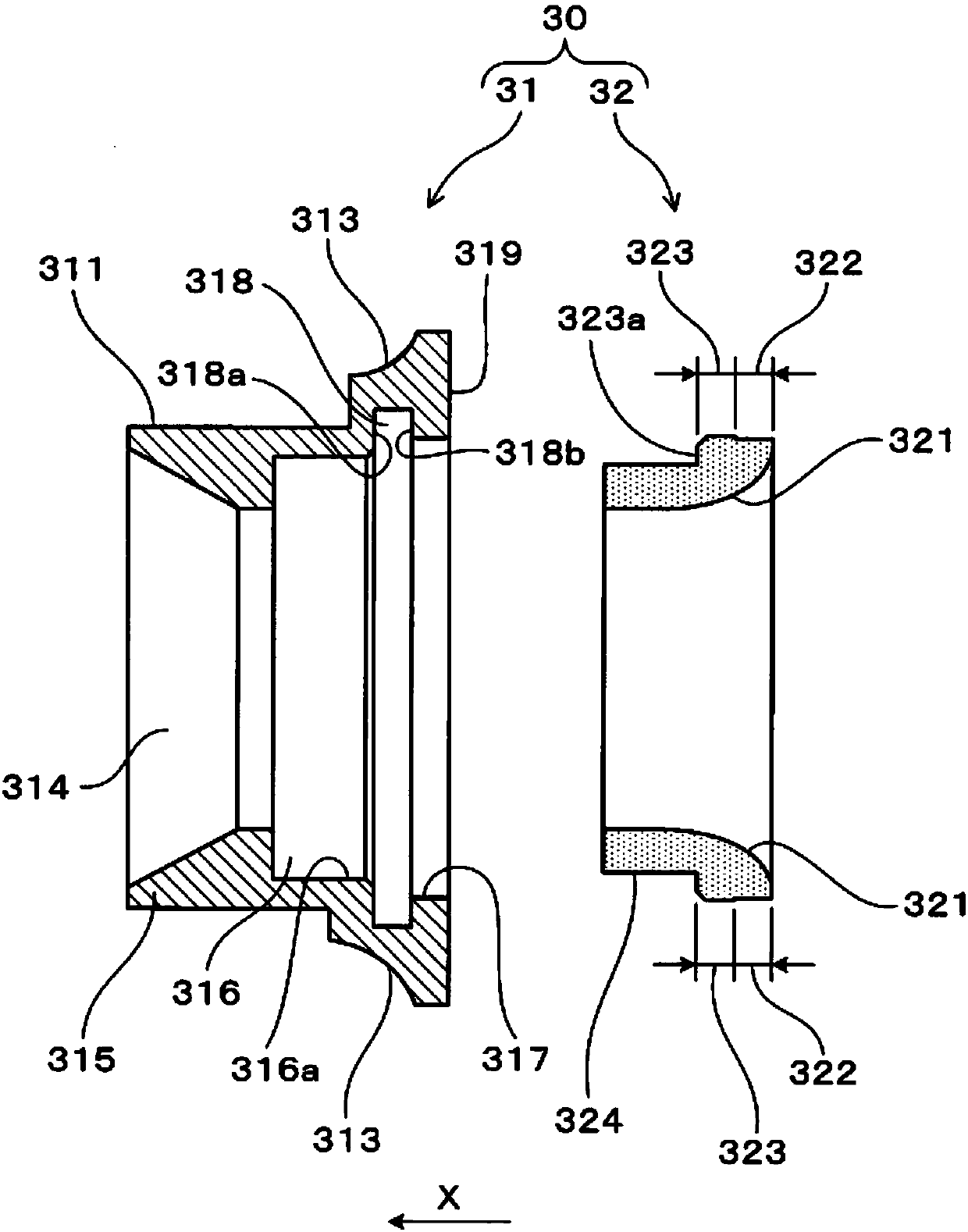

[0064] like figure 2 As shown, the shield portion 30 includes: an elastically deformable annular sliding member 32 whose inner peripheral surface 321 forms a shield surface 321 ; and an annular sliding member fixing portion 31 for fixing the sliding member 32 .

[0065] like image 3 As shown, the slide member fixing part 31 has: a press-fit recess 317 into which the slide member 32 is press-fit; The manner of depression is formed along the circumferential direction.

[0066] The sl...

Embodiment 2

[0107] In the compressor casing 1 that the supercharger of this example is used, as Figure 7 As shown, the sliding member 32 does not have a cylindrical portion 324 ( Figure 4 ), for the wall surface 318a on the front side in the press-in direction X of the groove portion 318, the end portion 323a on the front side in the press-in direction X of the slide member 32 and the front side in the press-in direction X of the groove portion 318 of the slide member fixing portion 31 The wall surface 318a abuts against. Thereby, the slide member 32 is positioned in the axial direction X at the end portion 323a on the front side in the press-fitting direction X. As shown in FIG. In addition, the same code|symbol is attached|subjected to the structural element equivalent to Example 1, and the description is abbreviate|omitted.

[0108] According to this example, in addition to the function and effect achieved by providing the cylindrical portion 324 on the front side in the press-fit ...

Embodiment 3

[0110] In the compressor casing 1 that the supercharger of this example is used, as Figure 8 As shown, the slide member 32 has a notch 325 formed at the rear end of the bulge 323 in the press-fit direction X (ie, the boundary between the bulge 323 and the press-fit abutting portion 322 ). like Figure 8 As shown, the notch portion 325 is formed in the circumferential direction along the wall surface 318 b on the rear side in the press-fitting direction X of the groove portion 318 . The notch portion 325 is a groove having a V-shaped cross-sectional shape in the axial direction X, and is formed uniformly over the entire circumferential direction. In addition to the V-shape, the cross-sectional shape of the notch portion 325 may be U-shaped, rectangular, arc-shaped, or the like. In addition, the same code|symbol is attached|subjected to the structural element equivalent to Example 1, and the description is abbreviate|omitted.

[0111] The depth of the notch 325 (from the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com