Filtering reducer with high reliability and precision

A reducer, a reliable technology, applied in portable lifting devices, gear transmissions, belts/chains/gears, etc., can solve problems such as poor dynamic performance, reduced reliability, jamming, etc., to reduce Hertzian contact stress and improve contact Stress, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

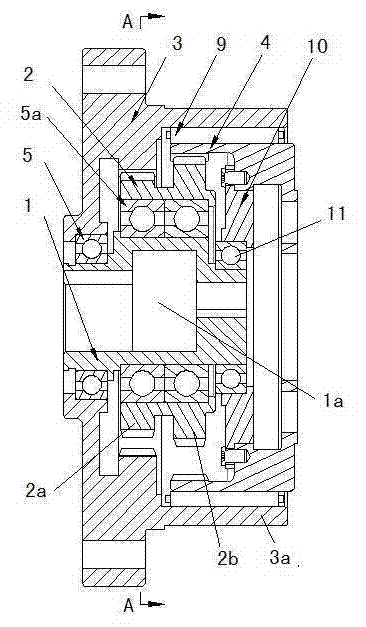

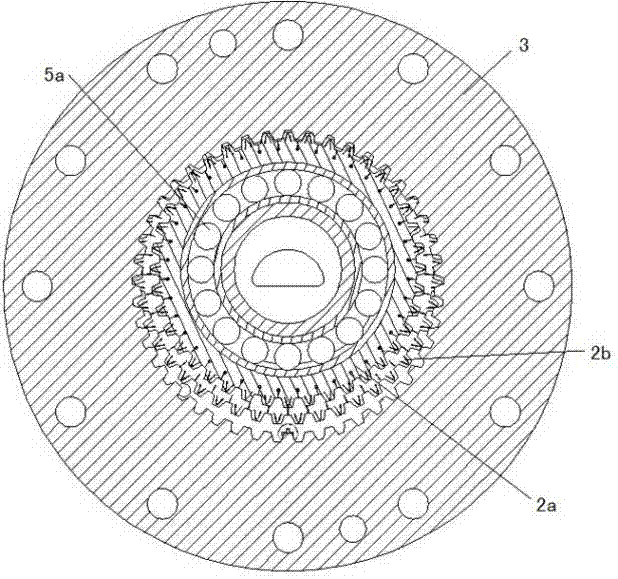

[0049] Such as figure 1 Shown is a schematic structural diagram of an embodiment of the high-reliability precision filter reducer of the present invention. The high-reliability precision filter reducer of this embodiment includes a power input eccentric shaft 1, a double gear 2, and a fixed internal gear 3 and a power output internal gear 4 that are both rotatably fitted on the power input eccentric shaft 1 and a power output internal gear 4. The fixed internal gear 3 and the power output internal gear 4 are rotatably fitted on the power input eccentric shaft 1 through bearings 5 respectively.

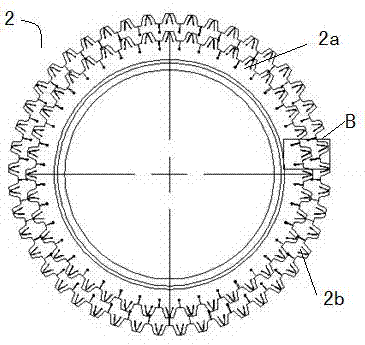

[0050] The power input eccentric shaft 1 is provided with an eccentric section 1a that is eccentrically arranged relative to its axis, and the dual gear 2 includes an external gear I 2a and an external gear II 2b, and the dual gear 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com